A mesoporous reverse water gas shift catalyst and its preparation method

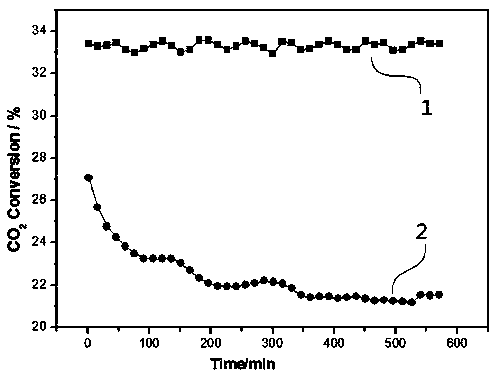

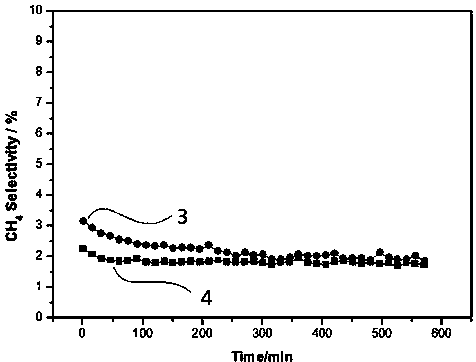

A technology for changing catalysts and reverse water gas, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high energy consumption, stability and selectivity to be improved, and achieve less side effects of methanation, The effect of low Ni content and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A mesoporous reverse water gas shift catalyst and a preparation method thereof, the specific steps are:

[0017] 1) Preparation of SBA-16 carrier: Weigh 10~15 parts of F127 (tri-block copolymer), 25~35 parts of n-butanol, 400~600 parts of distilled water, and stir with a constant temperature magnetic stirrer at 43~47°C for 0.8~1.2 h to mix well. Add 15-20 parts of hydrochloric acid with a concentration of 35-40%, slowly add 40-60 parts of TEOS (tetraethyl orthosilicate) dropwise, and stir for 20-25 hours at a constant temperature of 43-47°C. Transfer the mixed solution to a reaction kettle, conduct hydrothermal reaction at 105-120°C for 20-25 hours, cool to room temperature, filter with suction, and wash 2-5 times. Transfer the white powder to a watch glass, dry it at 75~90°C for 10~15h, put it into a muffle furnace, set the heating rate at 1~1.5°C / min, raise it from room temperature to 550~600°C, and calcine for 3~5h , to obtain the target product SBA-16 carrier. Th...

Embodiment 2

[0020] A mesoporous reverse water gas shift catalyst and its preparation method, the most preferred steps are:

[0021] 1) Weigh 10.0g of F127 (tri-block copolymer), 30.0g of n-butanol, 475ml of distilled water, and stir with a constant temperature magnetic stirrer at 45°C for 1 hour until they are evenly mixed. Add 17.5ml of 37% hydrochloric acid, slowly add 47.3g of TEOS (tetraethyl orthosilicate) dropwise, and stir at a constant temperature of 45°C for 24h. The mixed solution was transferred to a reaction kettle, subjected to hydrothermal reaction at 110° C. for 24 hours, cooled to room temperature, suction filtered, and washed several times to obtain a white powder. Transfer the white powder to a watch glass, dry it at 80°C for 12h, put it into a muffle furnace, set the heating rate at 1°C / min, and then calcine it for 4h after rising from room temperature to 600°C to obtain the target product mesoporous SBA-16 carrier .

[0022] 2) Preparation of 1%Ni / SBA-16 catalyst: We...

Embodiment 3

[0025] A mesoporous reverse water gas shift catalyst and its preparation method:

[0026] 1) Weigh 10.0g of F127 (tri-block copolymer), 30.0g of n-butanol, 475ml of distilled water, and stir with a constant temperature magnetic stirrer at 45°C for 1 hour until they are evenly mixed. Add 17.5ml of 37% hydrochloric acid, slowly add 47.3g of TEOS (tetraethyl orthosilicate) dropwise, and stir at a constant temperature of 45°C for 24h. The mixed solution was transferred to a reaction kettle, subjected to hydrothermal reaction at 110° C. for 24 hours, cooled to room temperature, suction filtered, and washed several times to obtain a white powder. Transfer the white powder to a watch glass, dry it at 80°C for 12h, put it into a muffle furnace, set the heating rate at 1°C / min, and then calcine it for 4h after rising from room temperature to 600°C to obtain the target product mesoporous SBA-16 carrier .

[0027] 2) Preparation of 1%Ni / SBA-16 catalyst: Weigh 0.05gNi(NO3 ) 2 ·6H 2 O,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com