Method for regenerating precious-metal mercury-free catalyst for acetylene hydrochlorination

A technology of acetylene hydrochlorination and mercury catalyst, which is applied in catalyst regeneration/reactivation, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problems of few research reports, achieve low operating cost, restore activity, prolong The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

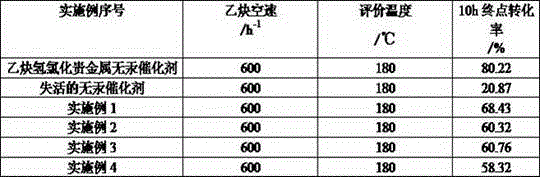

Embodiment 1

[0014] Take 10 g of the above-mentioned deactivated mercury-free catalyst and put it in a beaker, take 0.25 g of potassium thiocyanate and dissolve it in 20 ml of water, soak the deactivated catalyst in the potassium thiocyanate solution for 12 hours; dry at 120°C. Evaluations were performed on a fixed-bed microreactor.

Embodiment 2

[0016] Take 10 g of the above deactivated mercury-free catalyst and put it in a beaker, take 0.50 g of thiourea and dissolve it in 20 ml of water, soak the deactivated catalyst in the thiourea solution for 8 hours; dry at 120°C. Evaluations were performed on a fixed-bed microreactor.

Embodiment 3

[0018] Take 10 g of the above-mentioned deactivated mercury-free catalyst and put it in a beaker, take 0.40 g of dichloroacetonitrile sodium urate and dissolve it in 20 ml of water, soak the deactivated catalyst in the dichloroacetonitrile sodium urate solution for 16 hours; dry at 120°C. Evaluations were performed on a fixed-bed microreactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com