Porous carbon material for alkali lignin-based supercapacitor as well as preparation method and application thereof

A supercapacitor and alkali lignin technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, carbon preparation/purification, etc., can solve the problems of complex process and cost increase, achieve wide sources and reduce production costs , The effect of electrochemical cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] After dissolving the alkali lignin in the papermaking black liquor in water, adjust the pH to 9 with mineral acid, and take the filtrate after filtration; then continue to adjust the pH to 3 with inorganic acid, filter, wash 3 times, and obtain rough purified alkali lignin after drying white.

[0025] Weigh 35 g of the crudely purified alkali lignin and dissolve it in 870 mL of water, adjust the pH to neutral with dilute sulfuric acid, and perform suction filtration. Take the filtrate, continue to adjust the pH of the solution to 2.5 with dilute sulfuric acid, and reflux in an oil bath at 80°C for 8 hours. Filter, wash with water 3 times until neutral and dry for use. Weigh 10g alkali lignin, 10g polyether F127 and 32g Mg(CH 3 COO) 2 4H 2 O, dissolved in 550mL of tetrahydrofuran and water mixed solution with a volume ratio of 1:1, added 2mL of formaldehyde and 1.5mL of hydrochloric acid, and fully stirred evenly. The above mixed liquid was dried at 75° C. to obtain...

Embodiment 2

[0028] Take 500mL of papermaking black liquor and dilute it into 1000mL of water, adjust the pH to neutral with dilute hydrochloric acid, and perform suction filtration. Take the filtrate, continue to adjust the pH of the solution to 2, and reflux in an oil bath at 90°C for 8 hours. Filter, wash with water twice until neutral and dry to obtain alkali lignin for use. Get 10g alkali lignin, 15g polyether F127 and 42.6g Mg(CH 3 COO) 2 4H 2O, dissolved in 600mL of tetrahydrofuran and water mixed solution with a volume ratio of 1:1, added 2mL of formaldehyde and 1.3mL of hydrochloric acid, and fully stirred evenly. The above mixed liquid was dried at 70° C. to obtain a dark brown lumpy solid. Then under the protection of nitrogen, heat from room temperature to 70°C at a rate of 10°C / min, heat to 400°C at a rate of 2°C / min, and then heat from 400°C to 1000°C at a rate of 2°C / min for carbonization, and keep at 1000°C 30min, and then continue to feed nitrogen to cool to room temp...

Embodiment 3

[0031] After dissolving the alkali lignin in the papermaking black liquor in water, adjust the pH to 9 with mineral acid, and take the filtrate after filtration; then continue to adjust the pH to 3 with inorganic acid, filter, wash 3 times, and obtain rough purified alkali lignin after drying white.

[0032] Weigh 30 g of the crudely purified alkali lignin and dissolve it in 800 mL of water, adjust the pH to neutral with dilute sulfuric acid, and perform suction filtration. Take the filtrate, continue to adjust the pH of the solution to 2, and reflux in an oil bath at 80°C for 9 hours. Filter, wash with water 3 times until neutral and dry for use. Weigh 10g alkali lignin, 32g polyether F127 and 21.3g Mg(CH 3 COO) 2 4H 2 O, dissolved in 400mL of a mixed solution of tetrahydrofuran and water with a volume ratio of 4:6, added 2mL of formaldehyde and 1.34mL of hydrochloric acid, and fully stirred evenly. The above mixed liquid was dried at 70° C. to obtain a dark brown lumpy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

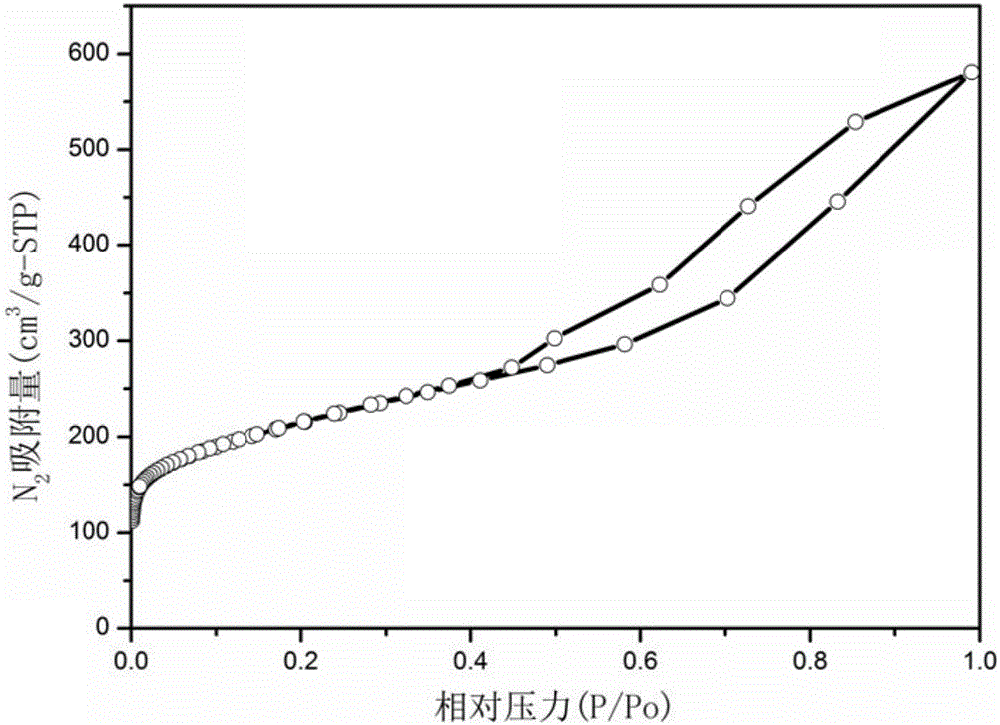

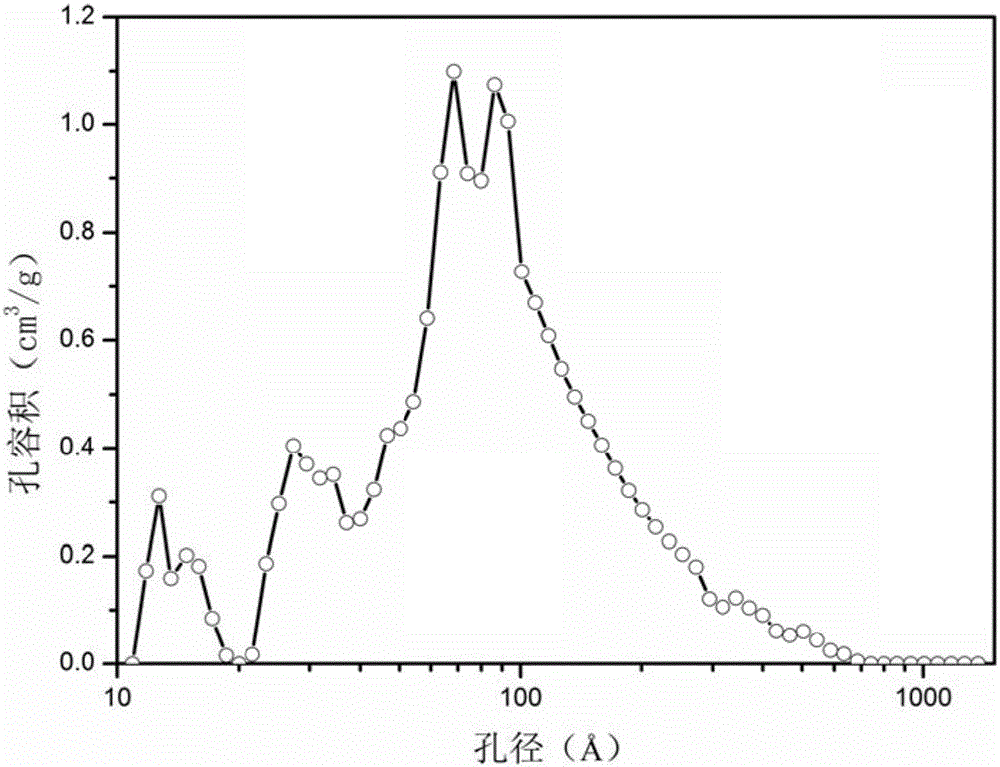

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

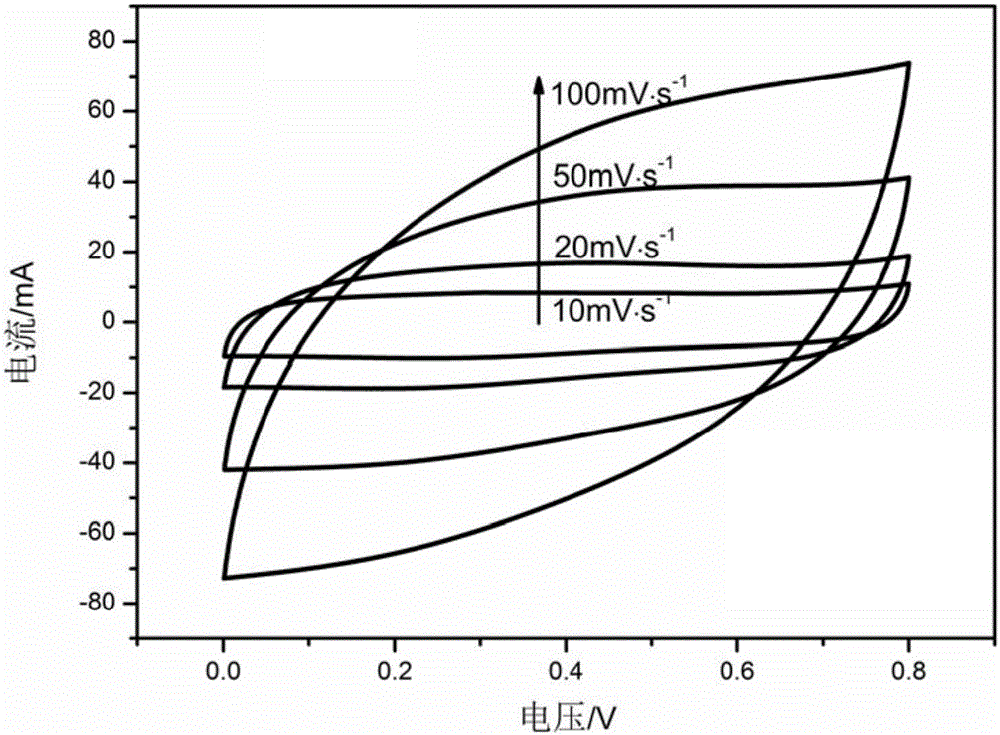

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com