A method for synthesizing analcime from fly ash

A synthesis method and technology of fly ash, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of long hydrothermal time, environmental pollution, land occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

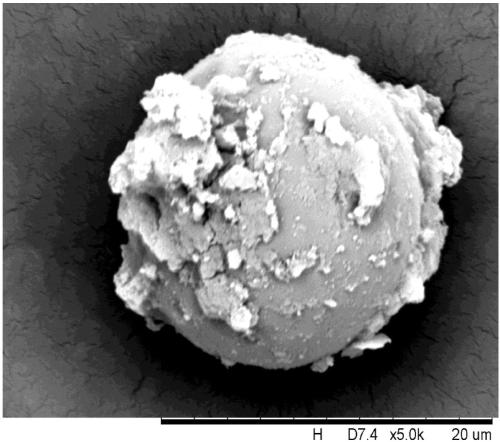

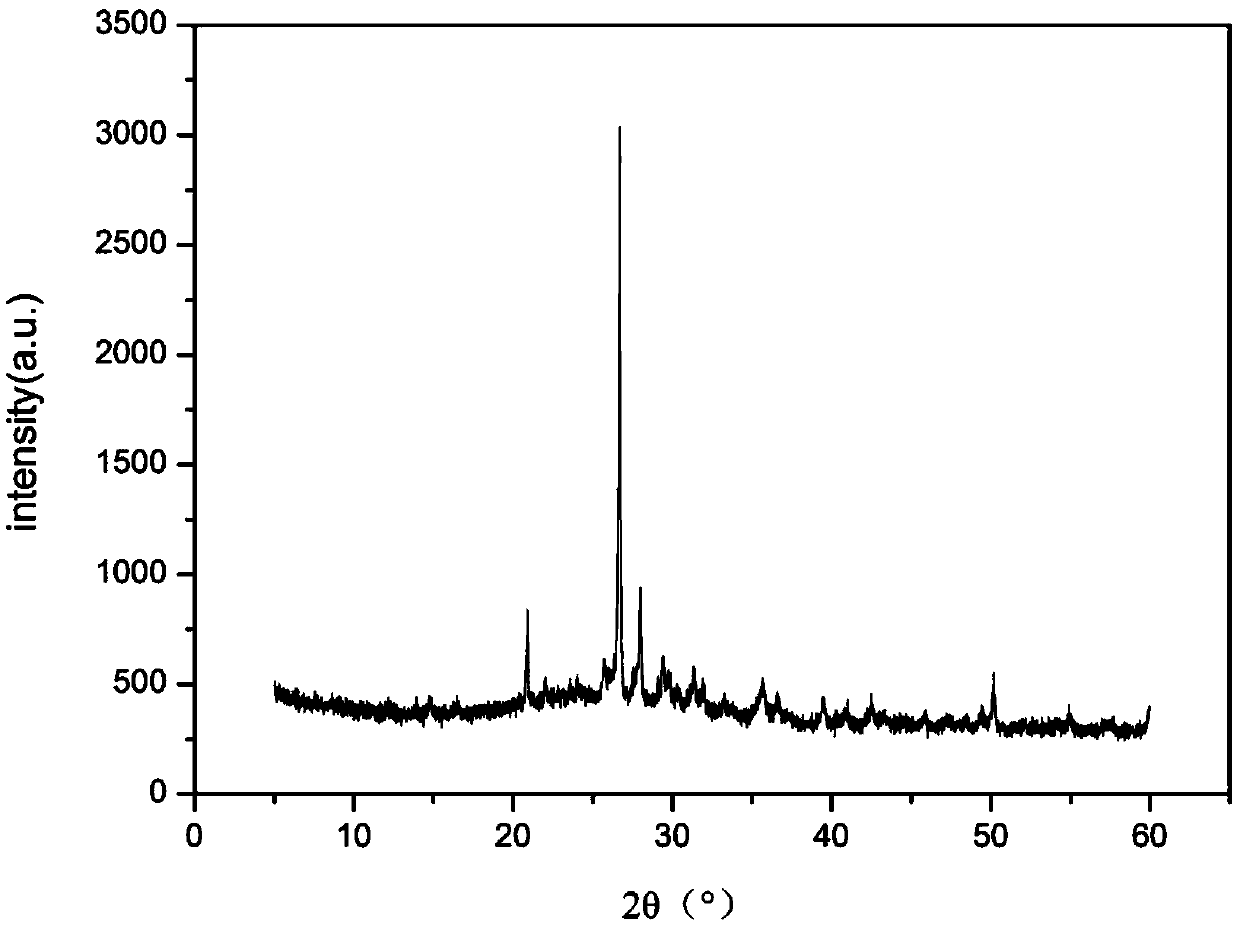

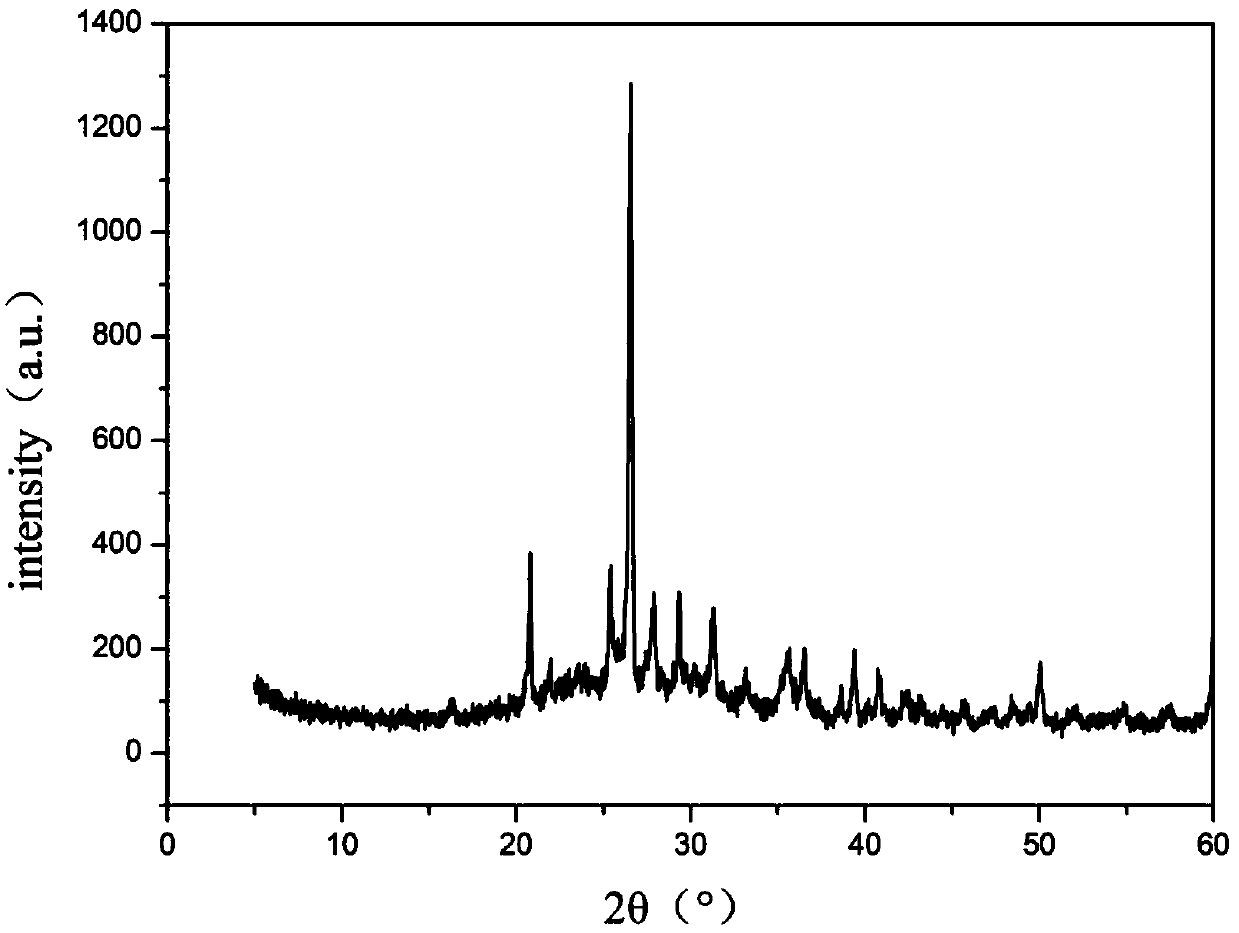

Image

Examples

Embodiment 1

[0041] 1): Take the fly ash of a power plant and grind it into fine ash with a grinder. The particle size after grinding is 200 mesh;

[0042] 2): Take 30g of the ground product, put it in a crucible, and put it in a muffle furnace for calcination at 550°C for 2h;

[0043] 3): Take 20g of the calcined product, soak it in 200ml hydrochloric acid solution with a concentration of 4mol / L, stir and react at 90°C for 4h, then filter it, wash it with distilled water until pH=6.0, and dry it at 105°C ;

[0044] 4): Take step 3), add 35g of sodium silicate, 5.6g of sodium hydroxide, 4.7g of concentrated sulfuric acid, and 280ml of distilled water to 10g of dry material after treatment, then stir and age at room temperature for 12h, then transfer the mixture to water In the thermal reaction kettle, seal it well and conduct crystallization reaction at 140°C for 24 hours. After the reaction is completed, take it out and cool it to room temperature, pour off the supernatant, filter the s...

Embodiment 2

[0047] 1): Take the fly ash of a power plant and grind it into fine ash with a grinder. The particle size after grinding is 150 mesh;

[0048] 2): Take 30g of the ground product, place it in a crucible, and put it in a muffle furnace for calcination at 850°C for 1.5h;

[0049] 3): Take 20g of the calcined product, soak it in 200ml hydrochloric acid solution with a concentration of 4mol / L, stir and react at 90°C for 2h, then filter it, wash it with distilled water until pH=6.0, and dry it at 105°C ;

[0050] 4): Take 10g of dry material after step 3), add 38g of sodium silicate, 5.6g of sodium hydroxide, 4.7g of concentrated sulfuric acid, 280ml of distilled water, then stir and age at room temperature for 10h, then transfer the mixture to a hydrothermal In the reactor, seal it well and conduct crystallization reaction at 140°C for 24 hours. After the reaction is completed, take it out and cool it to room temperature, pour off the supernatant, filter the solid product, and wa...

Embodiment 3

[0053] 1): Take the fly ash of a power plant and grind it into fine ash with a grinder. The particle size after grinding is 100 mesh;

[0054] 2): Take 30g of the ground product, place it in a crucible, and put it in a muffle furnace for calcination at 750°C for 1.5h;

[0055] 3): Take 20g of the calcined product, soak it in 200ml hydrochloric acid solution with a concentration of 4mol / L, stir and react at 90°C for 2h, then filter it, wash it with distilled water until pH=6.0, and dry it at 105°C ;

[0056] 4): Take 10g of dry material after step 3), add 37g of sodium silicate, 5.6g of sodium hydroxide, 4.7g of concentrated sulfuric acid, 300ml of distilled water, then stir and age at room temperature for 10h, then transfer the mixture to a hydrothermal In the reactor, seal it well and conduct crystallization reaction at 170°C for 12 hours. After the reaction is completed, take it out and cool it to room temperature, pour off the supernatant, filter the solid product, and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com