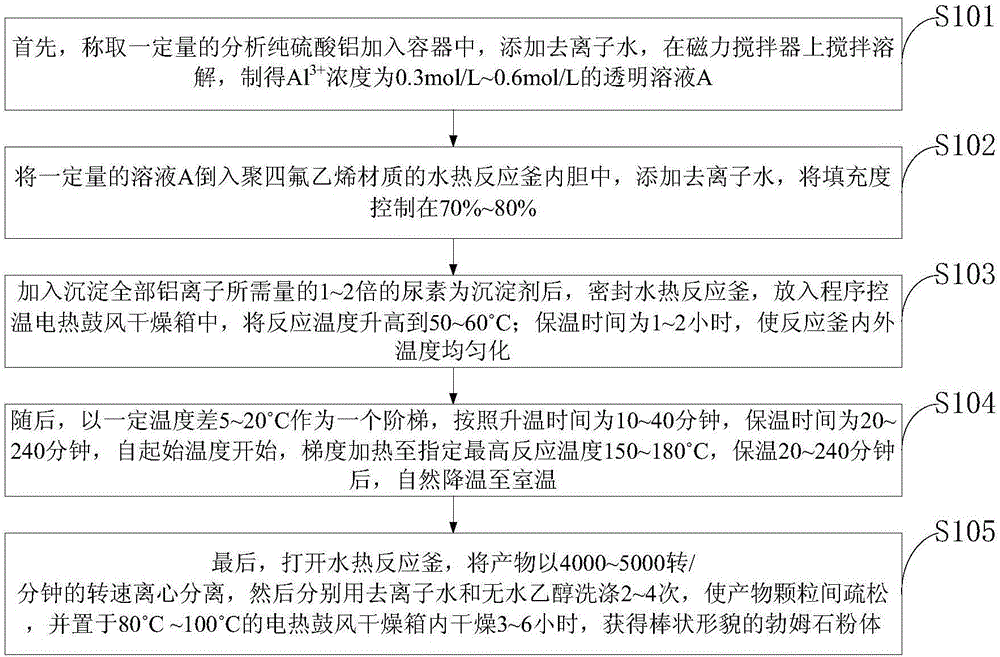

Method for preparing rod-like boehmite powder by gradient-heating hydrothermal process

A gradient heating and hydrothermal technology, applied in the preparation of alumina/hydroxide, etc., to achieve the effect of outstanding innovation, obvious comprehensive advantages and obvious environmental protection advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) First, weigh a certain amount of analytically pure aluminum sulfate reagent, add it to a container, add deionized water, stir it on a magnetic stirrer to dissolve it, and prepare Al 3+ A transparent solution A with a concentration of 0.5mol / L;

[0052] 2) Pour 20ml of solution A into the liner of a polytetrafluoroethylene hydrothermal reaction kettle with a volume of 50ml, add 20ml of deionized water, and control the filling degree at 80%;

[0053] 3) After adding 2.730g of urea with a purity of 99% as a precipitating agent, seal the hydrothermal reaction kettle, put it into a programmed temperature-controlled electric blast drying oven, raise the reaction temperature to 60°C, and keep it warm for 90 minutes, so that Realize the homogenization of the temperature inside and outside the reactor. The amount of urea used is 1.5 times the amount required for the precipitation of all aluminum ions.

[0054] 4) Then, with a temperature difference of 10°C as a step, the he...

Embodiment 2

[0059] 1) First, weigh a certain amount of analytically pure aluminum sulfate reagent, add it to a container, add deionized water, stir it on a magnetic stirrer to dissolve it, and prepare Al 3+ A transparent solution A with a concentration of 0.4mol / L;

[0060] 2) Pour 20ml of solution A into a 50ml Teflon-made hydrothermal reactor liner, add 15ml of deionized water, and control the filling degree to 70%;

[0061] 3) After adding 2.912g of urea as a precipitant, seal the hydrothermal reaction kettle, put it into a programmed temperature-controlled electric blast drying oven, raise the reaction temperature to 50°C, and maintain it for 120 minutes, so as to achieve the internal and external temperature of the reaction kettle. of homogenization. The amount of urea used is twice the amount required for the precipitation of all aluminum ions.

[0062] 4) Subsequently, with a temperature difference of 15°C as a step, the heating time is 20 minutes, and the holding time is 40 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com