A kind of ultra-high-strain high-strength thermal insulation material and its preparation method

A thermal insulation material and high-strength technology, applied in the field of building thermal insulation materials, can solve the problems of low strength, poor load-bearing capacity, easy cracking, etc., and achieve the effects of low water absorption, high thermal insulation efficiency, and good ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

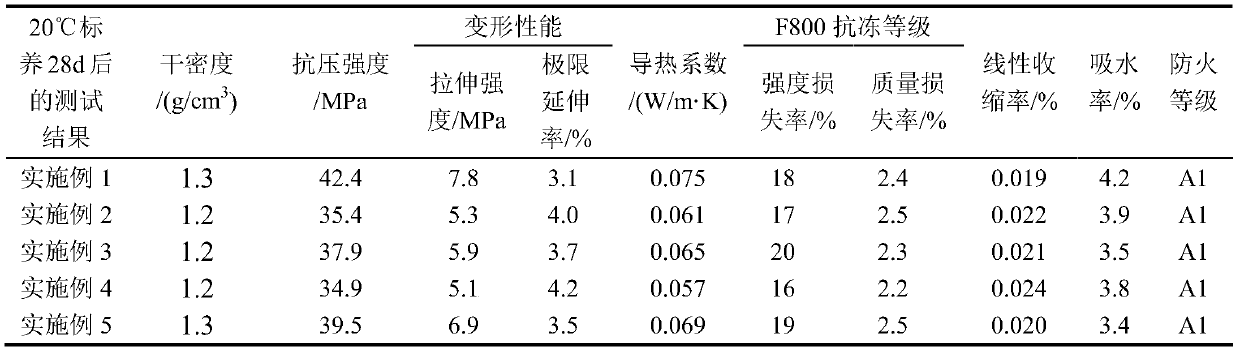

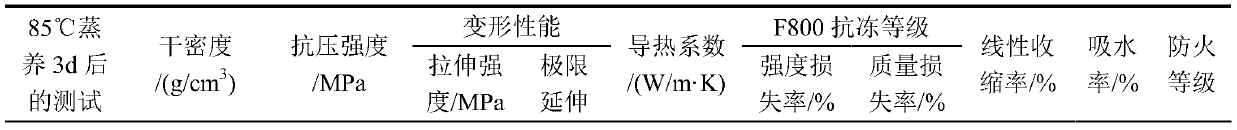

Examples

Embodiment 1

[0027] An ultra-high-strain and high-strength thermal insulation material, the material is composed of: the amount of mixing water is expressed as a water-cement ratio of 0.20, the volume percentage of fibers is 1.7%, and the other components are composed of the following components in mass percentages Composition: 48% of cement, 14% of silica fume, 5% of calcium powder, 5% of fly ash, 25% of sand, 0.039% of aminosilane modifier, 2.861% of water reducer, and foaming agent of 0.1%.

[0028] Among them, cement is grade 52.5 Portland cement; silica fume is commercially available common silica fume, and its SiO 2 The content is greater than 92%; the calcium carbonate content of calcium powder is greater than 95%wt, and the average particle size is 5-20μm; the fly ash is high-quality Class F, Class I low-calcium fly ash, in which the mass content of free CaO is less than 1%; the fiber It is polyvinyl alcohol (PVA) fiber, the fiber length is 6mm-12mm, the diameter is 12-39μm, the e...

Embodiment 2

[0030] An ultra-high-strain and high-strength thermal insulation material, the material is composed of: the amount of mixing water is expressed as a water-cement ratio of 0.24, the volume percentage of fibers is 2.3%, and other components are composed of the following components in mass percentages Composition: 30% of cement, 10% of silica fume, 17% of calcium powder, 17% of fly ash, 23% of sand, 0.026% of aminosilane modifier, 2.834% of water reducer, and foaming agent of 0.14%.

[0031] Among them, cement is grade 52.5 Portland cement; silica fume is commercially available common silica fume, and its SiO 2 The content is greater than 92%; the calcium carbonate content of calcium powder is greater than 95%wt, and the average particle size is 5-20μm; the fly ash is high-quality Class F, Class I low-calcium fly ash, in which the mass content of free CaO is less than 1%; the fiber It is polyvinyl alcohol (PVA) fiber, the fiber length is 6mm-12mm, the diameter is 12-39μm, the el...

Embodiment 3

[0033] An ultra-high-strain and high-strength thermal insulation material, the material is composed of: the amount of mixing water is expressed as a water-cement ratio of 0.22, the volume percentage of fibers is 2.0%, and other components are composed of the following components in mass percentages Composition: 33% of cement, 6% of silica fume, 16% of calcium powder, 23% of fly ash, 19% of sand, 0.019% of aminosilane modifier, 2.851% of water reducing agent, and foaming agent of 0.13%.

[0034] Among them, cement is grade 52.5 Portland cement; silica fume is commercially available common silica fume, and its SiO 2 The content is greater than 92%; the calcium carbonate content of calcium powder is greater than 95%wt, and the average particle size is 5-20μm; the fly ash is high-quality Class F, Class I low-calcium fly ash, in which the mass content of free CaO is less than 1%; the fiber It is polyethylene (PE) fiber, the fiber length is 6mm-12mm, the diameter is 12-39μm, the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com