Slow release fertilizer for inhibiting soil urease activity and preparation method

A technology of urease activity and slow-release fertilizer, which is applied to nitrogen, potassium, and phosphate fertilizers. It can solve problems such as high soil enzyme activity, excessive urea hydrolysis, and unsatisfactory fertilizer efficiency, so as to inhibit urease activity, reduce decomposition, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

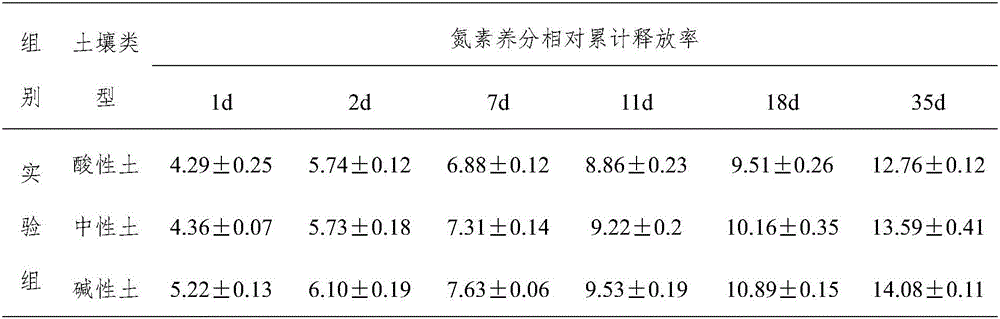

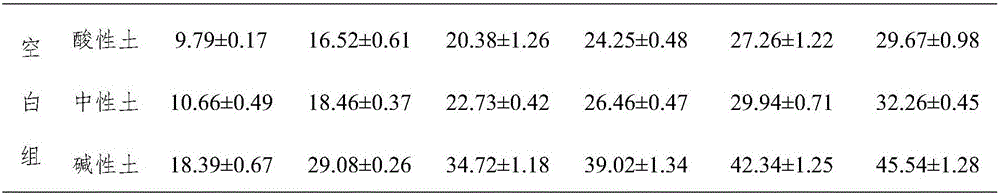

Examples

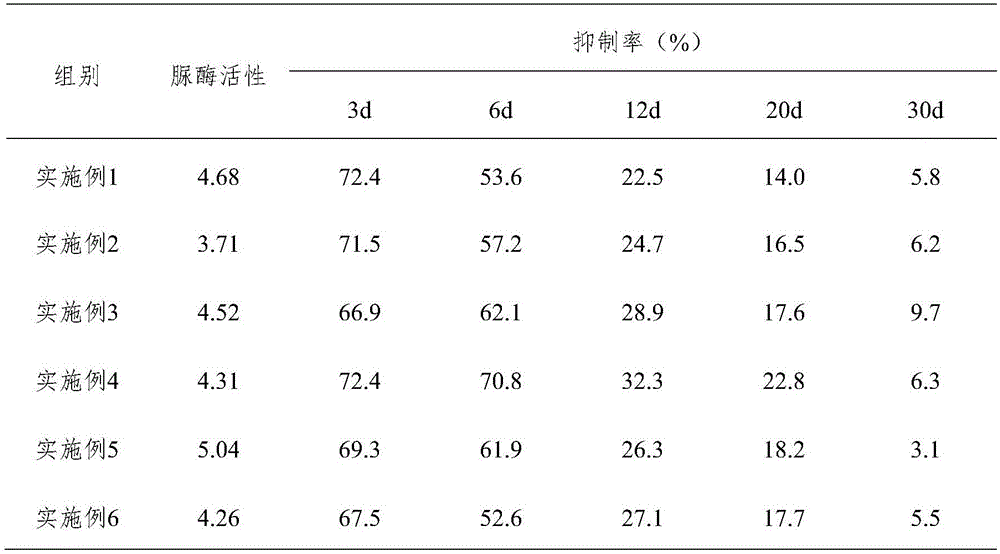

Embodiment 1

[0017] Formula: urea 18kg, humus 3kg, potassium sulfate 16kg, urea phosphate 13kg, gossypol acetate 1kg, tung oil 1kg;

[0018] Preparation:

[0019] (1) Granule preparation: Pour humic acid and molten urea into the reaction kettle at a ratio of 1:6, add methylal solution at the same time, stir and mix well, the stirring speed is 30r / min, the reaction temperature is 50-55°C, and the recovery Methylal, to obtain humic acid-urea complex, then add potassium sulfate and urea phosphate, the stirring speed is 80r / min, and spray dry to obtain an insoluble solid compound, the air temperature of the spray tower is 160 °C, and the air temperature of the tower At 90°C, crush to 60-70 meshes to obtain the primary product.

[0020] (2) Coating: Put the first product into the coating machine, set the speed at 600r / min, and the temperature at 65-68°C, start the hot air blower to preheat the urea granules, then add tung oil to the surface of the tumbling urea granules, Until the particle su...

Embodiment 2

[0022] Formula: urea 36kg, humus 4kg, potassium sulfate 25kg, urea phosphate 18kg, gossypol acetate 3kg, tung oil 3kg;

[0023] Preparation:

[0024] (1) Granule preparation: Pour humic acid and molten urea into the reaction kettle at a ratio of 1:9, add methylal solution at the same time, stir and mix well, the stirring speed is 50r / min, the reaction temperature is 65-70°C, and the recovery Methylal, to obtain humic acid-urea complex, then add potassium sulfate and urea phosphate, the stirring speed is 120r / min, and spray dry to obtain an insoluble solid compound, the air temperature of the spray tower is 180°C, and the air temperature of the tower is 110 ° C, crushed to 60 ~ 70 mesh, that is, to obtain the primary product.

[0025] (2) Coating: Put the first product into the coating machine, set the speed at 700r / min, and the temperature at 72-75°C, start the hot air blower to preheat the urea granules, then add tung oil to the surface of the tumbling urea granules, Until ...

Embodiment 3

[0027] Formula: urea 28kg, humus 4kg, potassium sulfate 20kg, urea phosphate 15kg, gossypol acetate 2kg, tung oil 2kg;

[0028] Preparation:

[0029] (1) Granule preparation: Pour humic acid and molten urea into the reaction kettle at a ratio of 1:7, add methylal solution at the same time, stir and mix well, the stirring speed is 40r / min, the reaction temperature is 60-65°C, and recover Methylal, to obtain humic acid-urea complex, then add potassium sulfate and urea phosphate, the stirring speed is 100r / min, after spray drying, an insoluble solid compound is obtained, the air temperature of the spray tower is 170 ° C, and the air temperature of the tower is 100 ° C, crushed to 60 ~ 70 mesh, that is, to obtain the primary product.

[0030] (2) Coating: put the first product into the coating machine, set the speed at 650r / min, and the temperature at 68-72°C, start the hot air blower to preheat the urea granules, and then add tung oil to the surface of the tumbling urea granules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com