Potassium humate urea and preparation method thereof

A technology of potassium humate and humic acid, applied in the field of potassium humate urea and its preparation, can solve the problems of unbalanced supply, poor slow-release effect, uneven mixing of urine and potassium humate, etc., and achieve a good synergistic effect , Increase the granulation effect and ensure the effect of slow release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] A preparation method of potassium humate urea, comprising:

[0016] Prepare Potassium Humate.

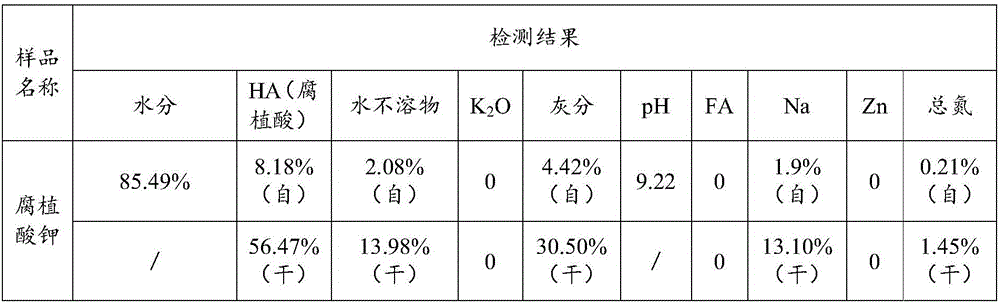

[0017] The raw material of potassium humate in this scheme is liquid potassium humate. The potassium humate can be purchased directly from the market, or can be prepared by yourself, as long as the raw material index of the potassium humate meets the standards in the table below.

[0018] Table 1 Potassium humate raw material index

[0019]

[0020] Note: The indicators in Table 1 are measured by mass fraction.

[0021] The mass content of humic acid in the liquid humic acid raw material for preparing the present potassium humate urea is ≥8.2%. It can be understood that the mass content of humic acid in the liquid humic acid raw material: 8.2%≤the mass content of humic acid in the liquid humic acid raw material<100%.

[0022] Take 1.6-2 parts by weight of the liquid potassium humate raw material and divide it into 0.5-0.8 parts by weight of the first potassium humate a...

Embodiment 1

[0044] Get 0.7kg of the first potassium humate, 2kg of the first superphosphate, 1kg of the first potassium chloride and 10kg of water and mix evenly to obtain a solution. Add the solution to 10 kg of black soil and mix evenly, then perform the first granulation at a temperature of 110° C. to obtain intermediate fertilizer granules.

[0045] Under mechanical stirring conditions, heat 95kg of urea to a molten state, add 4.75kg of water, 1.2kg of the second potassium humate, 5kg of the second superphosphate and 6kg of the second potassium chloride and mix well , to get urine. Add the intermediate fertilizer granules to the urine and mix them evenly, then transport them to the evaporation system to evaporate excess water, then transport them to the prilling tower, and carry out vacuum granulation at a temperature of 130°C and under normal pressure conditions to obtain humic fertilizers. Potassium urea.

Embodiment 2

[0047] Get 0.6kg of the first potassium humate, 4kg of the first superphosphate, 2kg of the first potassium chloride and 12kg of water and mix evenly to obtain a solution. After adding the solution to 14 kg of black soil and mixing evenly, at a temperature of 130° C., perform the first granulation to obtain intermediate fertilizer granules.

[0048] Under mechanical stirring conditions, heat 98kg of urea to a molten state, add 5.88kg of water, 1.4kg of the second potassium humate, 7kg of the second superphosphate and 7kg of the second potassium chloride and mix well , to get urine. Add the intermediate fertilizer granules to the urine and mix them evenly, then transport them to the evaporation system to evaporate excess water, then transport them to the prilling tower, and carry out vacuum granulation at a temperature of 140°C and under normal pressure conditions to obtain humic fertilizers. Potassium urea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com