L-citrulline succinate and preparation method and application thereof

A technology of citrulline succinate and citrulline, which is applied in the field of medicine and chemical industry, can solve the problems of lack of L-citrulline succinate, etc., and achieve the effects of enhancing body immunity, low production cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Microorganism fermentation method prepares L-citrulline aqueous solution, comprises the steps:

[0040] (1) plate activation, inoculate the bacterial strain (preservation number is CGMCC No.11567) on LB medium under aseptic conditions for cultivation, the cultivation temperature is 30°C, and the cultivation time is 24h;

[0041] (2) Expanded cultivation: pick a single colony from the LB plate of step (1) and receive it in the seed medium, the temperature of the expanded cultivation is 30°C, the shaking table speed is 200rpm, and the incubation time is 12h;

[0042] Seed medium (g / L): glucose 20, dipotassium hydrogen phosphate trihydrate 1.5, potassium dihydrogen phosphate 0.5, urea 2.5, manganese sulfate monohydrate 0.02, ferrous sulfate heptahydrate 0.02, biotin 10 -4 , VB1 2×10 -4 , arginine 0.2, magnesium sulfate heptahydrate 0.4, potassium hydroxide to adjust the pH to 6.5;

[0043] (3) Fermentation culture in a 5L fermenter: inoculate the expanded cultured bacter...

Embodiment 2

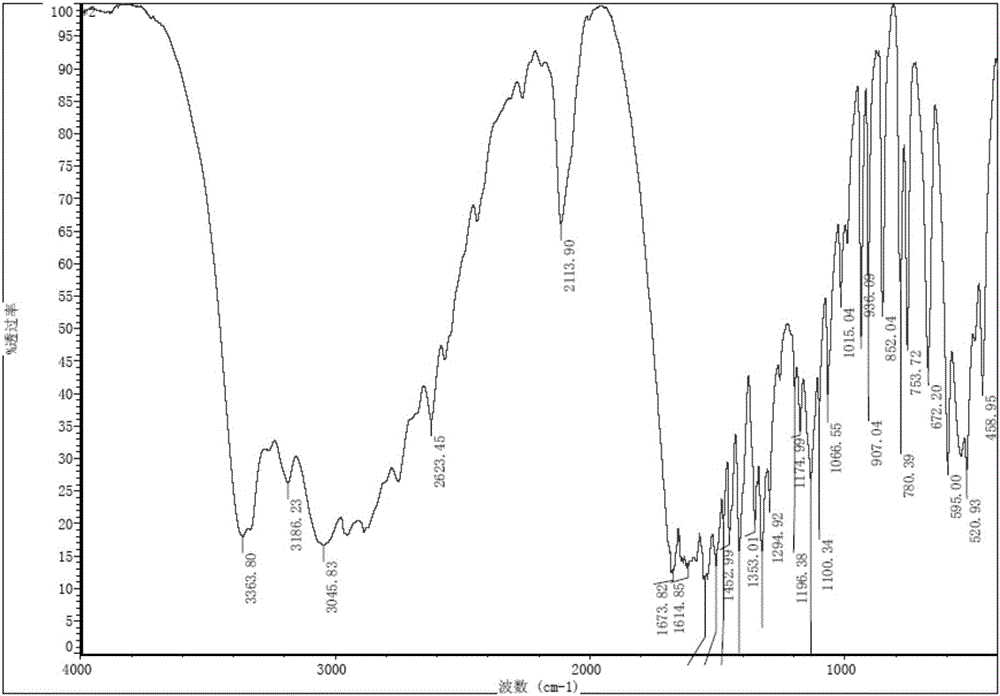

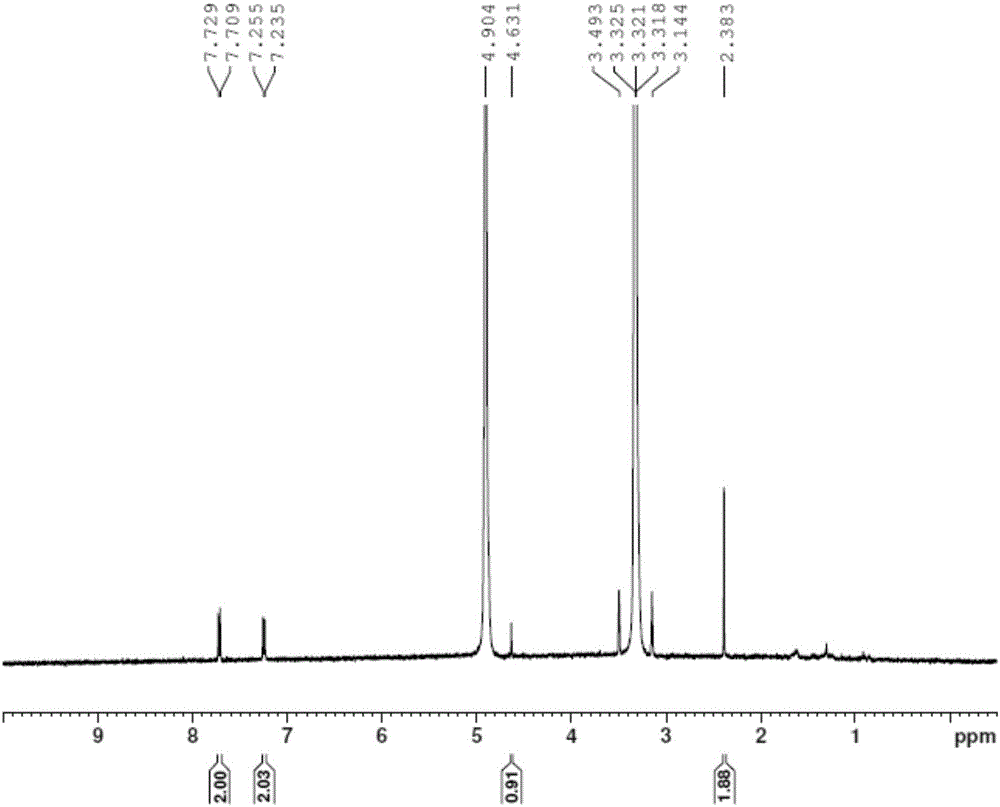

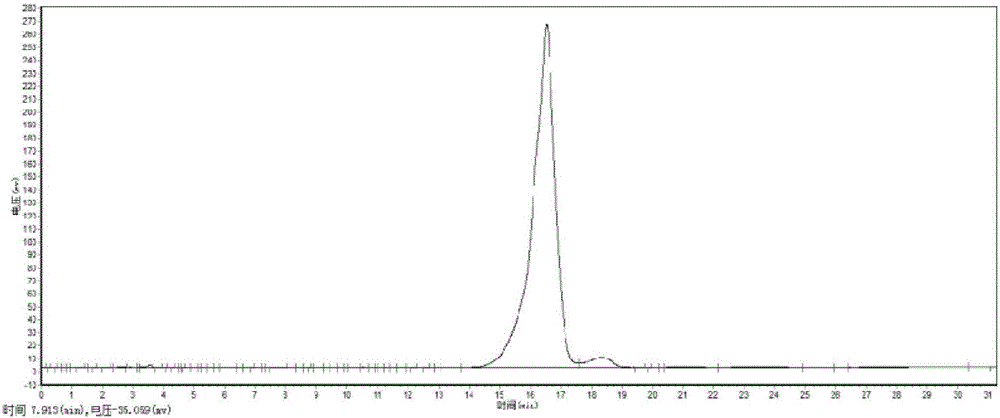

[0047] Configure the L-citrulline prepared in Example 1 into an aqueous solution with a concentration of 223g / L, take 20ml, add 1.5g of succinic acid, stir the reaction solution at 50°C until it becomes transparent (stirring time 40-45min), and dissolve the solution Cool down to room temperature, and add 11ml of absolute ethanol to make the solution quickly approach saturation. At room temperature, add 90 ml of 80% ethanol at 0.48 ml / min and keep stirring, the stirring speed is 200 rpm. Slowly lower the temperature of the solution to 4°C and cool overnight to crystallize, filter, wash, and dry the crystals in a vacuum oven. The product is 3.53g, and the yield is 64.4%. The infrared spectrum of the product is shown in figure 1 As shown in the hydrogen spectrum, see figure 2 shown in the liquid chromatogram image 3 As shown, the purity measured by high performance liquid chromatography was 97.5%.

Embodiment 3

[0049] Purify the L-citrulline fermented liquid prepared in Example 1 to obtain an aqueous solution of L-citrulline, concentrate the aqueous solution to 200g / L, take 22ml, add 1.5g of succinic acid, 0.5g of palladium Carbon, the temperature is 55°C and the reaction solution is stirred until it is transparent (stirring time is about 20-25min), the solution is cooled to room temperature, and 11ml of absolute ethanol is added to make the solution quickly approach a saturated state. At room temperature, 90 ml of 80% ethanol was added at 0.5 ml / min and stirred continuously, and the stirring speed was 150 rpm. Slowly lower the temperature of the solution to 4°C and cool overnight to crystallize, filter, wash, and dry the crystals in a vacuum oven. The product is 3.6406 g, the yield is 66.35%, and the purity measured by high performance liquid chromatography is 98.1%. After adding the catalyst, the reaction rate is nearly doubled, that is, the reaction time is shortened from 40-45min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com