A kind of preparation method of degradable corn cob biomass water retaining agent

A technology of corncob and water-retaining agent, which is applied in the field of biomass materials, can solve the problems of limited water-absorbing capacity, limited water-retaining time, and high cost of water-retaining agents, and achieve the effects of inhibiting water evaporation, increasing adsorption rate, and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

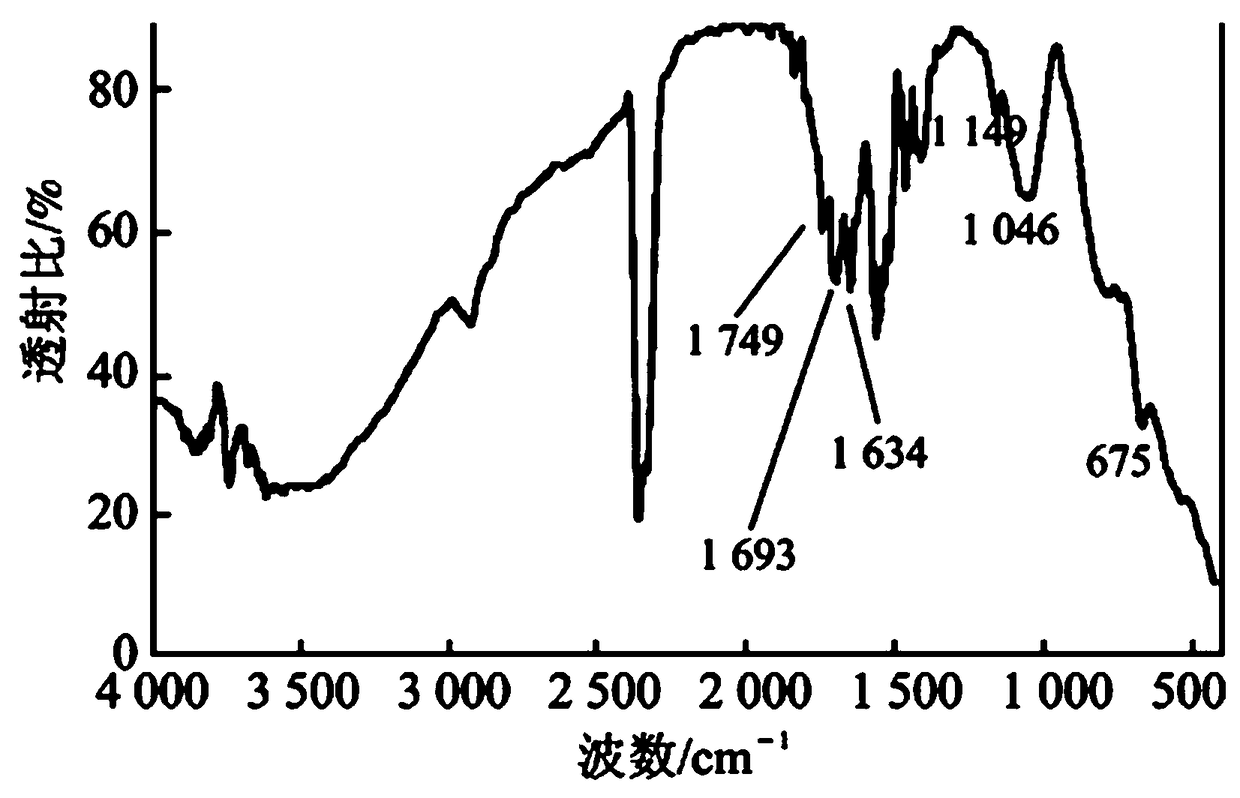

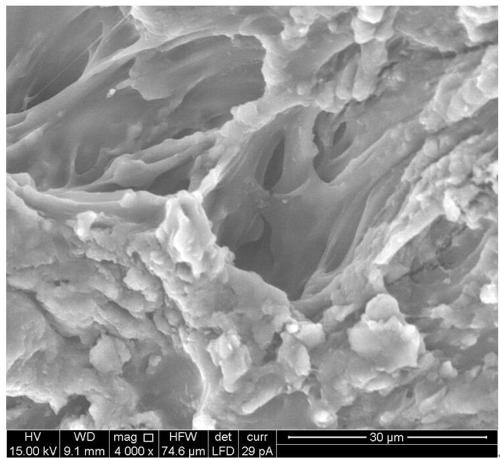

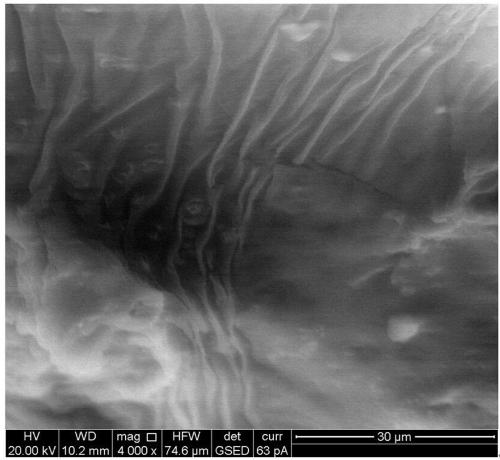

[0030] A preparation method of a degradable corncob biomass water-retaining agent, the specific preparation process is as follows: First, use a pulverizer to crush the dried corncob to 200 mesh, weigh 1000g and modify it with microwave radiation at 100w for 10min, and after microwave radiation The corncobs were put into 2L 0.5mol / L acetic anhydride solution, reacted at 60°C for 4h, then rinsed with water for 2-3 times, dried and set aside.

[0031] Weigh 10g of the secondary modified corncob powder and disperse it in 150ml of water, gelatinize at 50°C for 0.5h; then add 80g of acrylamide to the system, stir evenly, and add 0.12g of N,N- Methylbisacrylamide, 0.8g ammonium persulfate-sodium bisulfite until gel is formed, finally washed with 95% ethanol, and dried to obtain a degradable corncob biomass water retaining agent.

Embodiment 2

[0033] A preparation method of a degradable corncob biomass water-retaining agent, the specific preparation process is as follows: First, use a pulverizer to crush the dried corncob to 100 mesh, weigh 1000g and modify it with microwave radiation at 200w for 5min, and after microwave radiation The corncobs were put into 4L 1mol / L formic anhydride solution, reacted at 30°C for 10h, then rinsed with water for 2-3 times, dried and set aside.

[0034] Weigh 10g of secondary modified corn cob powder and disperse in 200ml of water, gelatinize at 80°C for 1h; then add 50g of acrylamide to the system, stir evenly, and add 0.4g of N,N-dimethyl base formamide, 0.5g ammonium persulfate until the gel is formed, finally washed with 50% ethanol, and dried to obtain the degradable corncob biomass water retaining agent.

Embodiment 3

[0036] A preparation method of a degradable corncob biomass water-retaining agent, the specific preparation process is as follows: First, use a pulverizer to crush the dried corncob to 500 mesh, weigh 1000g and modify it by microwave radiation at 100w for 20min, and after microwave radiation The corn cobs were put into 2L 0.8mol / L phthalic anhydride solution, reacted at 80°C for 6h, then rinsed with water for 2-3 times, dried and set aside.

[0037] Weigh 10g of secondary modified corncob powder and disperse in 100ml of water, gelatinize at 65°C for 0.8h; then add 100g of acrylamide to the system, stir evenly, and under nitrogen protection, add 0.1g of glycerol, 0.6 g potassium persulfate, finally washed with 50% ethanol, and dried to obtain degradable corncob biomass water retaining agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com