A kind of itaconic acid-based water-based UV resin and preparation method thereof

An itaconic acid-based water-based and aconic acid-based water-based technology, applied in polyester coatings, coatings and other directions, can solve the problems of complex preparation process, unfavorable wide application, relatively expensive isocyanate, etc., and achieve high biomass content and cost. Low, short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

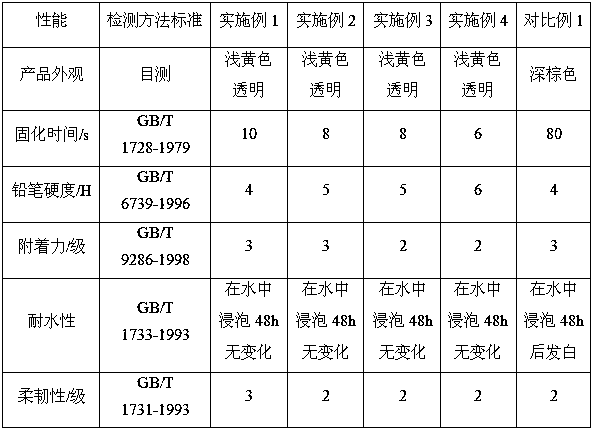

Examples

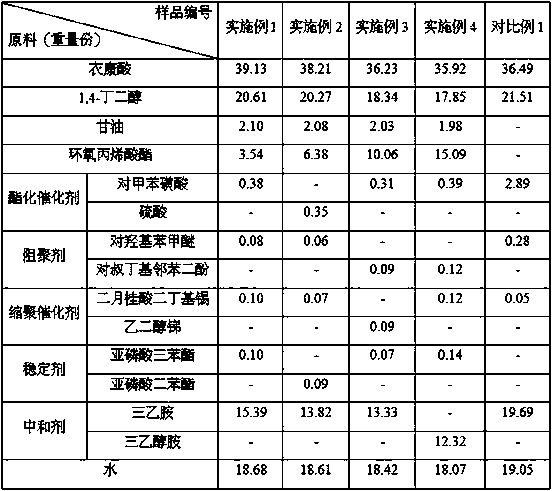

Embodiment 1

[0046] (1) According to the raw materials and dosage of Example 1 in Table 1, add itaconic acid, 1,4-butanediol, glycerin, epoxy acrylate, p-toluenesulfonic acid and p-hydroxyanisole into the three-necked bottle, and Protected with nitrogen, heated to 130°C for 1 hour, then depressurized to a vacuum of 0.02MPa for dehydration until anhydrous was formed, then cooled to 70°C to obtain a precondensed polymer;

[0047] (2) According to the raw materials and dosage of Example 1 in Table 1, add dibutyltin dilaurate and triphenyl phosphite to the precondensed polymer obtained in step (1), and depressurize to a vacuum of 0.09MPa. After heating to 140°C and reacting for 4 hours, cool down to 80°C, then add triethylamine, and finally add water, and stir evenly to obtain itaconic acid-based water-based UV resin.

[0048] After testing, the pH value of the obtained itaconic acid-based water-based UV resin product was 7.4, and the solid content was 81%.

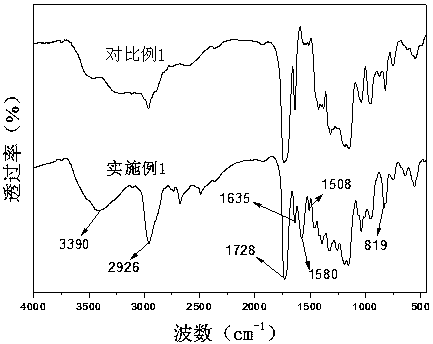

[0049] Depend on figure 1 It can...

Embodiment 2

[0051] (1) According to the raw materials and dosages of Example 2 in Table 1, add itaconic acid, 1,4-butanediol, glycerin, epoxy acrylate, sulfuric acid and p-hydroxyanisole into a three-necked bottle, and pass through nitrogen protection , heated to 125°C for 1.5h, then depressurized to a vacuum of 0.03MPa for dehydration until anhydrous was formed, then cooled to 70°C to obtain a precondensed polymer;

[0052] (2) According to the raw materials and dosage of Example 2 in Table 1, add dibutyltin dilaurate and diphenyl phosphite to the precondensed polymer obtained in step (1), and under the condition of decompression to a vacuum of 0.1MPa, After heating to 140°C and reacting for 3 hours, cool down to 80°C, then add triethylamine, and finally add water, and stir evenly to obtain itaconic acid-based water-based UV resin.

[0053] After testing, the pH value of the obtained itaconic acid-based water-based UV resin product was 7.1, and the solid content was 81%.

Embodiment 3

[0055] (1) According to the raw materials and dosage of Example 3 in Table 1, add itaconic acid, 1,4-butanediol, glycerin, epoxy acrylate, p-toluenesulfonic acid and p-tert-butylcatechol into the three-necked bottle, Introduce nitrogen protection, heat to 135°C to react for 1 hour, then depressurize to a vacuum of 0.02MPa to react and dehydrate until anhydrous is formed, then cool to 60°C to obtain a precondensed polymer;

[0056] (2) According to the raw materials and dosage of Example 3 in Table 1, add ethylene glycol antimony and triphenyl phosphite to the precondensed polymer obtained in step (1), and heat under the condition of decompression to a vacuum degree of 0.09MPa After reacting at 150°C for 3 hours, lower the temperature to 65°C, then add triethylamine, and finally add water, and stir evenly to obtain itaconic acid-based water-based UV resin.

[0057] After testing, the pH value of the obtained itaconic acid-based water-based UV resin product was 7.0, and the soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com