Polylactic-acid ceramic-imitating material and preparation method thereof

A technology of imitation porcelain material and polylactic acid, which is applied in the field of polylactic acid plasticization, heat-resistant composite materials and its manufacturing, can solve the problems of poor toughness and thermal deformation temperature of polylactic acid, improve surface gloss, increase total crystallization speed, increase Effect of heat deflection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] It is made from the following raw materials in parts by weight:

[0027] 60 parts of polylactic acid resin,

[0028] 1 part tributyl citrate,

[0029] 0.3 parts of polyhydrazide imine compounds,

[0030] 10 parts of talcum powder,

[0031] 0.2 parts of stearylamide,

[0032] Mix the polylactic acid resin, plasticizer, organic nucleating agent, inorganic nucleating agent, and crystallization accelerator with a high-speed mixer, then add it to an internal mixer for mixing, melt and blend through a twin-screw extruder, and screw extrude The length-to-diameter ratio of the screw of the machine is 35:1, and the temperature in each area of the equipment is 170°C, 175°C, 180°C, 185°C, 190°C, 195°C, 200°C, after which the strands are extruded, water-cooled, moisture-absorbed, and pelletized. The obtained granular composite material is airtightly stored after being dried to prevent moisture.

Embodiment 2

[0034] It is made from the following raw materials in parts by weight:

[0035] 75 parts of polylactic acid resin,

[0036] 5.5 parts of polyethylene glycol,

[0037] 0.7 parts of polyhydrazide imine compounds,

[0038] 15 parts of talcum powder,

[0039] 5.0 parts of erucamide;

[0040] Mix the polylactic acid resin, plasticizer, organic nucleating agent, inorganic nucleating agent, and crystallization accelerator with a high-speed mixer, then add it to an internal mixer for mixing, melt and blend through a twin-screw extruder, and screw extrude The length-to-diameter ratio of the screw of the machine is 40:1, and the temperature of each zone of the equipment is 170°C, 175°C, 180°C, 185°C, 190°C, 195°C, 200°C, and then extrudes the strands, water-cools, absorbs moisture, and pelletizes. The obtained granular composite material is airtightly stored after being dried to prevent moisture.

Embodiment 3

[0042] It is made from the following raw materials in parts by weight:

[0043] 90 parts of polylactic acid resin,

[0044] 10 parts of epoxy soybean oil,

[0045] 1 part of polyhydrazide imine compound,

[0046] 20 parts of talcum powder,

[0047] 10 parts of ethylene bis stearamide,

[0048] Mix the polylactic acid resin, plasticizer, organic nucleating agent, inorganic nucleating agent, and crystallization accelerator with a high-speed mixer, then add it to an internal mixer for mixing, melt and blend through a twin-screw extruder, and screw extrude The length-to-diameter ratio of the screw of the machine is 45:1, and the temperatures in each area of the equipment are 170°C, 175°C, 180°C, 185°C, 190°C, 195°C, and 200°C, after which the strands are extruded, water-cooled, moisture-absorbed, and pelletized. The obtained granular composite material is airtightly stored after being dried to prevent moisture.

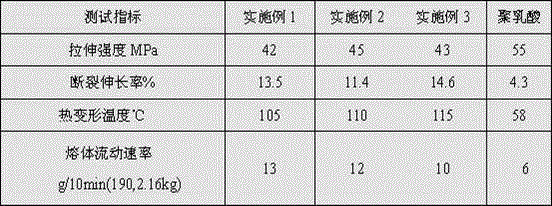

[0049] Further illustrate the effect of the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com