A biodegradable high-barrier plastic product and its preparation method

A plastic product and biodegradation technology, applied in the field of plastic packaging, can solve the problems of material performance degradation, less application, and easy precipitation of plasticizers, etc., to reduce thermal decomposition, speed up molding speed, increase mechanical strength and barrier properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

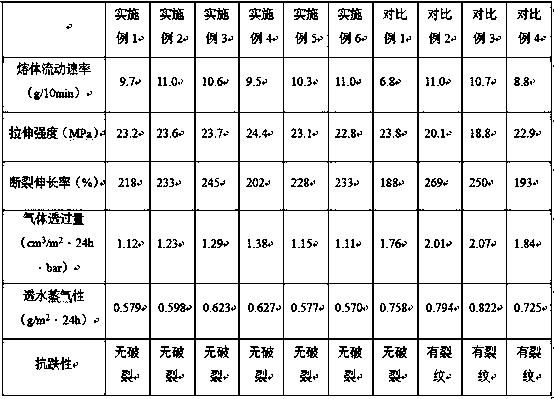

Examples

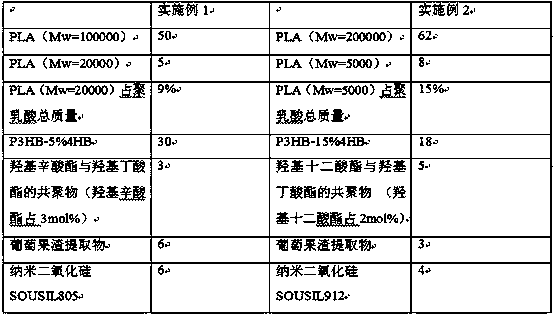

Embodiment 1

[0037] According to the formula shown in Table 2, the grape pomace extract was dissolved in methanol, and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and copolymer of hydroxycaprylate and hydroxybutyrate were added (the molar content of hydroxycaprylate is 3%), stir to obtain a suspension; raise the temperature and keep it at 50~60°C, stir until the solvent is completely volatilized, and obtain a modified polyhydroxyalkanoate; prepare the modified polyhydroxyalkanoate Ester, polylactic acid PLA and hydrophobic nano-silica are mixed evenly in a high-speed mixer, then melted and plasticized in a twin-screw extruder, and pelletized to obtain plastic pellets. The plasticizing temperature is 140°C; finally, the plastic pellets are heated And the injection molded embryo is stretched and blow molded into a plastic bottle in a blow mold at a molding temperature of 55°C.

Embodiment 2

[0039] According to the formula shown in Table 2, the grape pomace extract was dissolved in methanol, and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and copolymerization of hydroxydodecanoate and hydroxybutyrate were added (the molar content of hydroxydodecanoic acid ester is 2%), stir to obtain a suspension; raise the temperature and keep it at 50~60°C, stir until the solvent is completely volatilized, and obtain a modified polyhydroxyalkanoate; prepare the modified polyhydroxyalkanoate Hydroxy fatty acid ester, polylactic acid PLA and hydrophobic nano-silica are mixed evenly in a high-speed mixer, then melted and plasticized in a twin-screw extruder, and pelletized to obtain plastic pellets. The plasticizing temperature is 165°C; finally, the plastic The pellets are heated and injection-molded into embryos, stretched and blow-molded into plastic bottles in a blow-molding mold, and the molding temperature is 70°C.

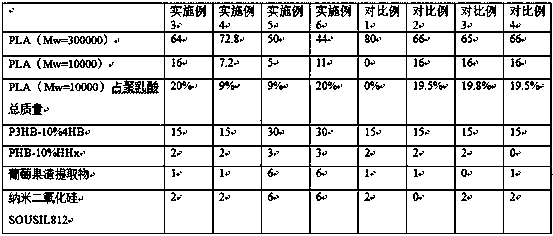

Embodiment 3

[0041] According to the formula shown in Table 2, the grape pomace extract was dissolved in methanol, and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3 -hydroxycaproic acid ester) (3-hydroxycaproic acid ester molar content is 10%), stirring to obtain a suspension; heating and maintaining at 50-60 ° C, stirring until the solvent is completely volatilized, to obtain a modified polyhydroxyalkanoate; Mix the prepared modified polyhydroxyalkanoate, polylactic acid PLA and hydrophobic nano-silica in a high-speed mixer, then melt and plasticize in a twin-screw extruder, and granulate to obtain plastic pellets. The plasticizing temperature is 170°C; Finally, the plastic pellets are heated and injection-molded into embryos, stretched and blown into plastic bottles in a blow mold, and the molding temperature is 65°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com