Bottom sizing agent for polyurethane sealant and preparation method of bottom sizing agent

A polyurethane sealant and primer technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of restricted product market expansion, slow research and development progress, etc., and achieve long open time, short surface drying time, and durability. Good moist heat performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

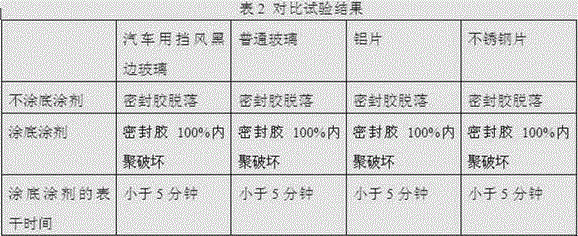

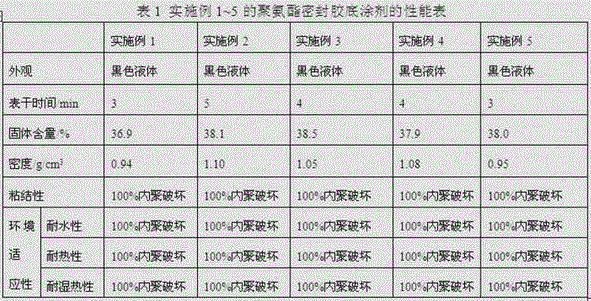

Examples

preparation example Construction

[0078] The present invention also includes the preparation method of polyurethane sealant primer, comprising the following steps:

[0079] ①Put the polyester polyol at 100~120°C, pressure ≥0.092MPa, remove water for 1~2 hours, cool down to 60~70°C, add diisocyanate 1 to it, and react at 80~85°C for 2~3 hours , lower the temperature to 45-55°C, then add a silane-capping agent to it, react for 0.5-1 hour, then cool down to 20-30°C to obtain a silane-terminated polyurethane polymer;

[0080] Among them, the mass ratio of polyester polyol, diisocyanate 1, and silane blocking agent is 10~20:2~5:1~4;

[0081] The diisocyanate 1 is 4,4'-diphenylmethane diisocyanate, toluene diisocyanate, isophorone diisocyanate, hexamethylene diisocyanate, xylylene diisocyanate or liquefied MDI;

[0082] The silane capping agent is 3-aminopropyltrimethoxysilane, γ-aminopropyltriethoxysilane, γ-mercaptopropyltrimethoxysilane, anilinomethyltrimethoxysilane or γ-aminoethyl Aminopropyltrimethoxysilane;...

Embodiment 1

[0108] A polyurethane sealant primer, consisting of the following raw materials: 20 kg of silane-terminated polyurethane polymer, 20 kg of modified polyurethane, 1 kg of p-toluenesulfonyl isocyanate, 2 kg of carbon black, and anti-settling agent Organic bentonite 1kg, adhesion promoter N-75 2kg, solvent ethyl acetate 30kg and catalyst bismorpholino diethyl ether 0.05kg.

[0109] Its preparation method comprises the following steps:

[0110] ① Remove water from 30kg of polyester polyol at 100°C and pressure ≥ 0.092MPa for 1 hour, cool down to 60°C, add 6kg of 4,4`-diphenylmethane diisocyanate to it, and react at 80°C for 2 hours , lower the temperature to 45°C, then add 12kg of 3-aminopropyltrimethoxysilane to it, react for 0.5 hours, then lower the temperature to 20°C to obtain a silane-terminated polyurethane polymer;

[0111] ② Remove water from 30kg of acrylate polyol at 100°C and pressure ≥ 0.092MPa for 1 hour, cool down to 60°C, add 15kg of toluene diisocyanate into it, ...

Embodiment 2

[0114] A polyurethane sealant primer, consisting of the following raw materials: 30kg of silane-terminated polyurethane polymer, 30kg of modified polyurethane, 2kg of water-removing agent vinyltrimethoxysilane, 10kg of carbon black, and gas-phase anti-settling agent Silica 2kg, adhesion promoter TDI trimer 5kg, solvent butyl acetate 65kg and catalyst triethylamine 0.2kg;

[0115] Its preparation method comprises the following steps:

[0116] ① Put 40kg of polyester polyol at 120°C, pressure ≥ 0.092MPa, remove water for 2 hours, cool down to 70°C, add 10kg of isophorone diisocyanate to it, react at 85°C for 3 hours, cool down to 55°C , and then adding 2kg of γ-aminopropyltriethoxysilane to it, reacting for 1 hour, and cooling to 30°C to obtain a silane-terminated polyurethane polymer;

[0117] ② Remove water from 40kg of acrylate polyol at 120°C and pressure ≥0.092MPa for 2 hours, cool down to 70°C, add 6kg of hexamethylene diisocyanate to it, react at 85°C for 3 hours, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com