Method for rapidly preparing solid light-emitting material

A solid-state luminescent and fast technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high energy consumption and long preparation cycle, and achieve the effects of low energy consumption, low cost and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 0.5 g of citric acid, 0.17 g of methylamine hydrochloride, and 0.78 g of lanthanum chloride heptahydrate, place them in a mortar, grind them well and mix them evenly, transfer them to a conical flask, place them in a microwave oven for 4 minutes, and the reaction is over Then the solid luminescent material can be obtained.

Embodiment 2

[0026] Take 0.5 g of citric acid, 0.35 g of methylamine hydrochloride, and 0.39 g of lanthanum chloride heptahydrate, place them in a mortar, grind them well and mix them evenly, transfer them to a conical flask, place them in a microwave oven for pyrolysis for 1 minute, and the reaction is over Then the solid luminescent material can be obtained.

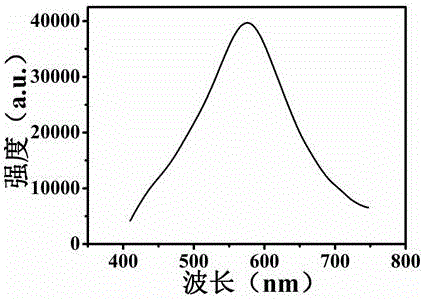

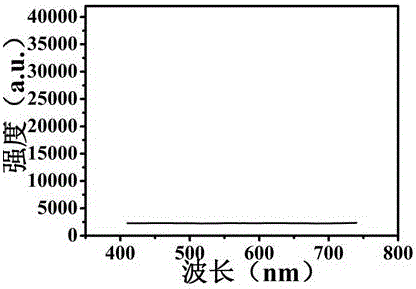

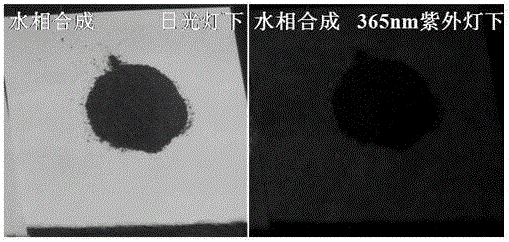

[0027] Such as figure 1 As shown, the maximum emission wavelength of the solid luminescent material prepared in Example 1 is about 580nm; figure 2 , image 3 As shown, the material prepared by the aqueous phase method has no obvious emission spectrum, and the solid has no fluorescence signal; as Figure 4 As shown, the solid-phase luminescent material prepared in Example 2 can see obvious yellow fluorescence under a 365nm ultraviolet lamp, and the product yield is high, and it has great application prospects in mass production and industrial promotion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com