Preparation method for forming spinel coating on surface of alloy

A spinel coating and alloy technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of easy burning of rare earth, short coating life, affecting the mechanical properties and welding performance of furnace tubes and other problems to achieve the effect of preventing excessive manganese content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

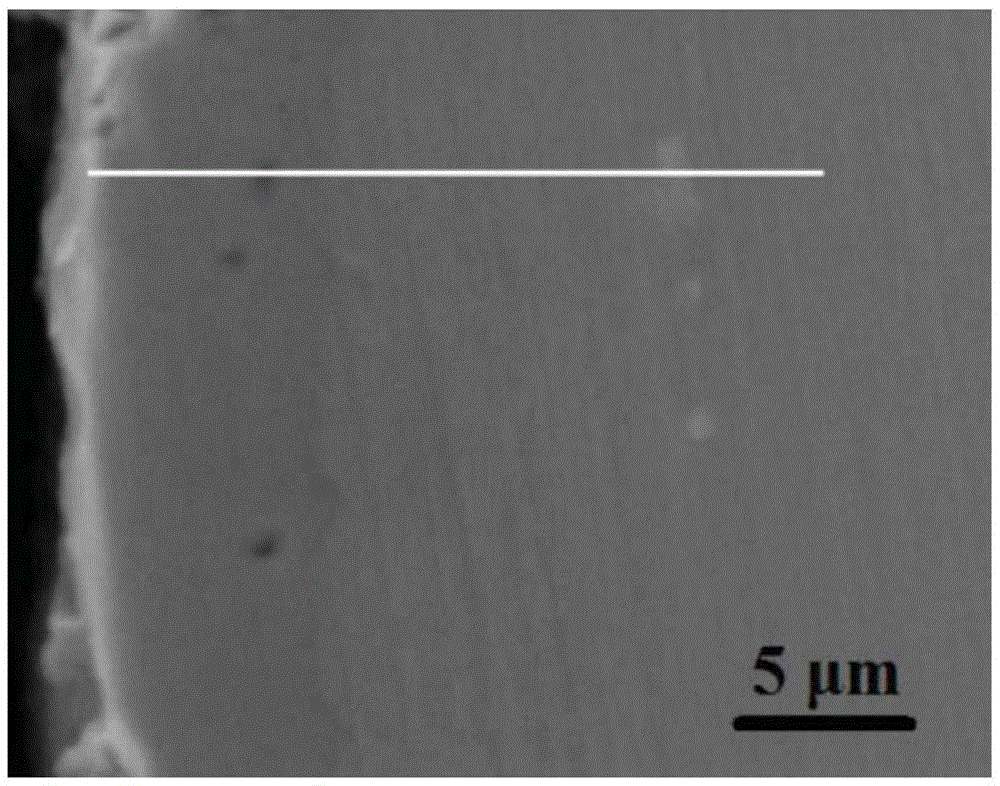

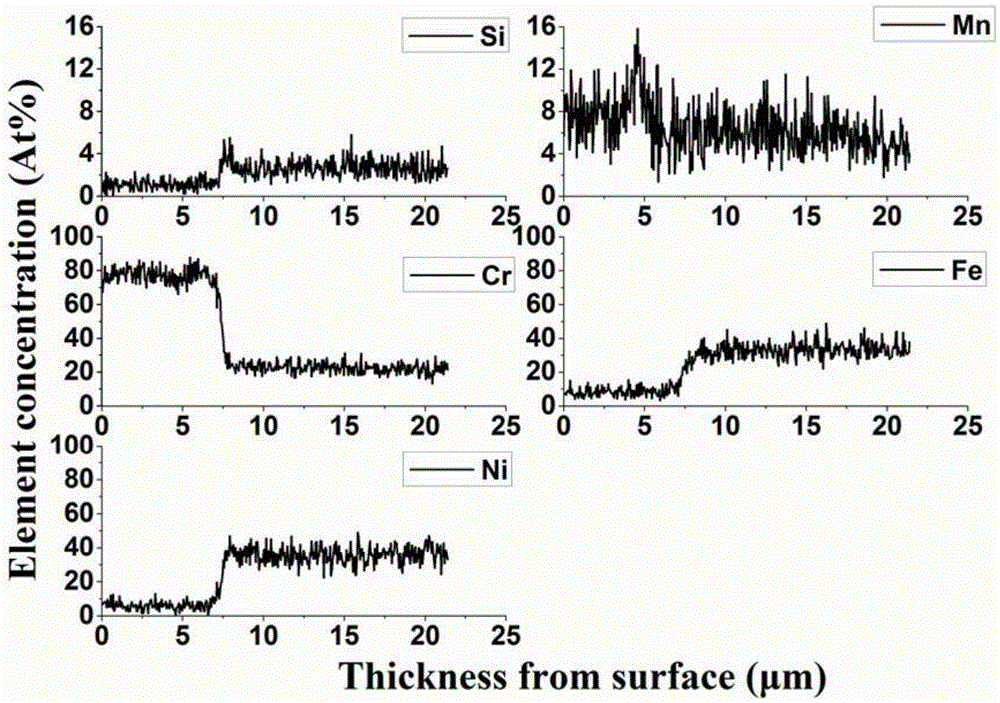

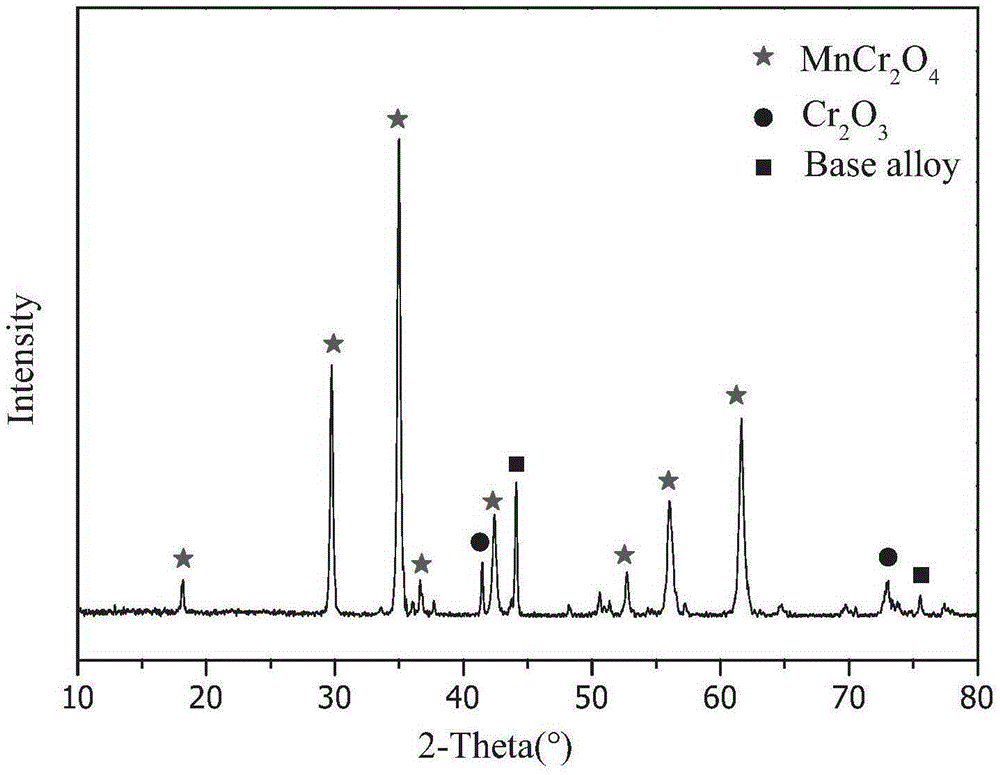

[0047] Example Prepared dense, uniform MnCr with a certain thickness on the surface of HP40 alloy 2 o 4 Spinel coating.

[0048] After degreasing and derusting the surface of the HP40 alloy material, put it into the infiltration tank together with the embedding infiltration agent. The mass percentage of the infiltration agent is: chromium powder 25%, ferromanganese powder (40% iron content) 30%, Ammonium chloride 1.5%, sodium fluoride 0.4%, cerium oxide 0.2%, the balance is Al 2 o 3pink. The infiltration tank is sealed with refractory mud, and then the infiltration tank is put into the muffle furnace for co-infiltration heat treatment. The heat treatment temperature in the muffle furnace is 1050°C, the holding time is 5h, and the cooling rate is 10°C / min. When the temperature in the furnace drops to 100°C, take out the seepage tank, soak the surface of the HP40 alloy material with 30% NaOH aqueous solution, clean it with clean water, and then place it in a tubular heat tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com