Wavelength scanning confocal micro-displacement measurement device and method

A wavelength scanning and measurement device technology, applied in the field of precision measurement, can solve the problems of inability to realize fast and precise scanning, high cost of large-stroke precision displacement, confocal microscope imaging and measurement speed limitations, etc., to avoid mechanical movement or disturbance, The effect of flexible design and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

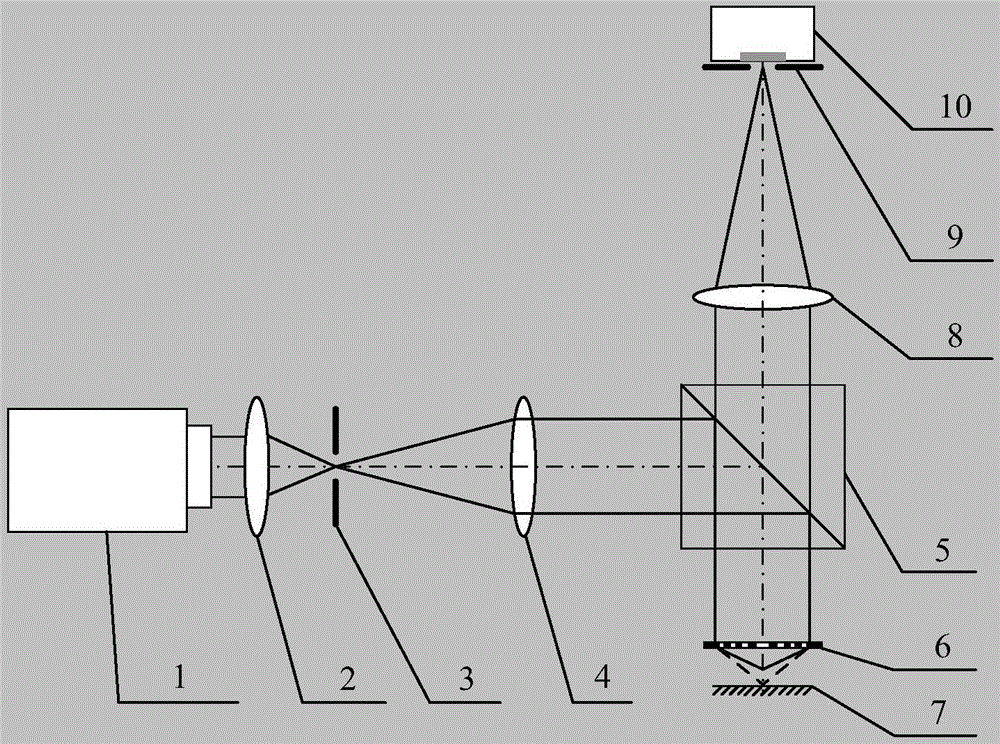

[0029] like figure 1 As shown, a wavelength-scanning confocal micro-displacement measuring device of the present invention has the working principle of its optical path system: a laser beam emitted by a wavelength-tunable laser 1 is focused by a converging lens 2, filtered by an illumination pinhole 3, and then collimated The lens 4 is collimated to form a parallel beam, and then reflected by the beam splitter 5. The reflected beam is converged by the binary structure Fresnel zone plate 6 to provide point illumination. Near the focal plane of the zone plate 6, the light beam reflected by the plane mirror or the sample 7 to be tested is transmitted by the beam splitter 5, converged by the collecting objective lens 8, filtered by the confocal detection pinhole 9, and finally passed by the photodetector 10 to receive and output a valid signal.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com