Gold-lead zirconate titanate nanocomposite ferroelectric thin film material and preparation method thereof

A ferroelectric thin film and nano-composite technology, applied in circuits, capacitors, electrical components, etc., can solve the problems of low polarization intensity and achieve the effect of increasing polarization intensity, simple method, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

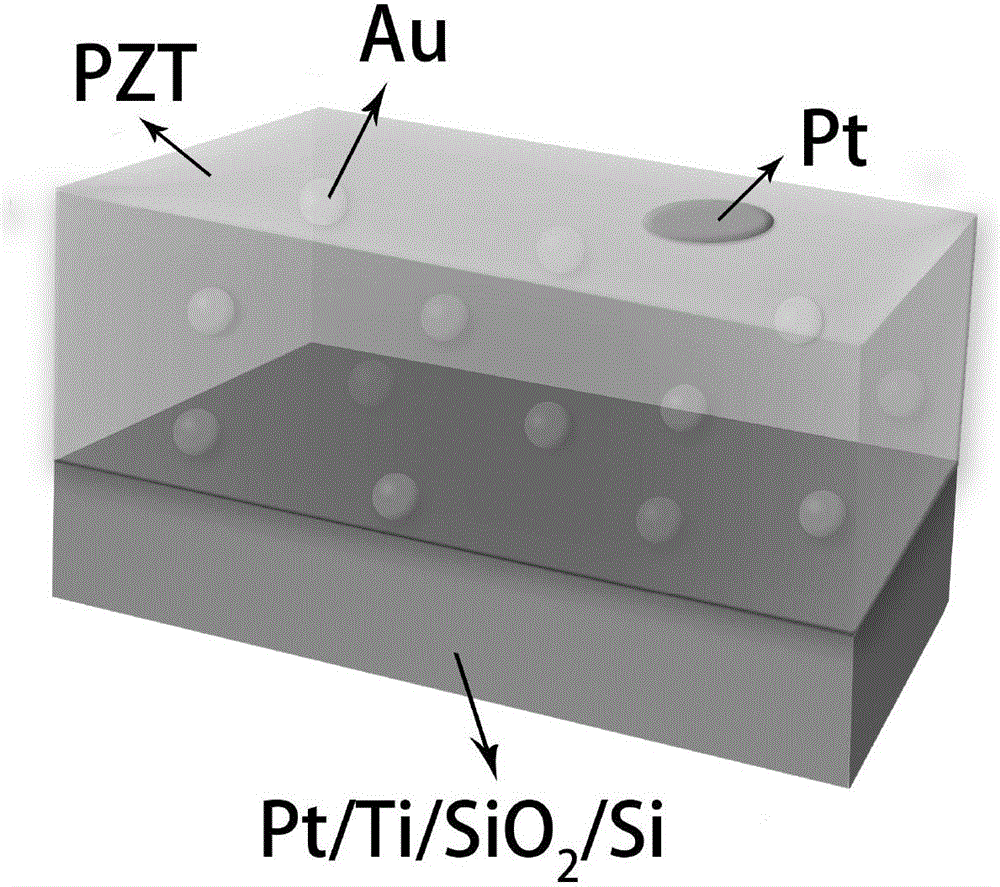

[0022] Embodiment 1 (molar composition is Au:0.6mol%, Pb (Zr 0.4 Ti 0.6 )O 3 :99.4mol%)

[0023] Step 1: Prepare the solution

[0024] With water, acetic acid and isopropanol as solvent, chloroauric acid, lead acetate, zirconium n-propoxide and titanium isopropoxide as solute, according to Pb:Ti:Zr molar ratio is 5:3:2, according to Au:Pb( Zr 0.4 Ti 0.6 )O 3 The molar ratio is 0.006:1, take chloroauric acid, lead acetate, zirconium n-propoxide and titanium isopropoxide, add water, acetic acid and isopropanol respectively with the concentration standard of 0.4mol / L, then carry out at room temperature Stir until the chloroauric acid, lead acetate, zirconium n-propoxide and titanium isopropoxide are all dissolved to obtain a light yellow transparent solution;

[0025] Step 2: Preparation of film material

[0026] (1) Using Pt / Ti / SiO 2 / Si(100) substrate. Drop the solution prepared in step 1 onto the substrate for spin coating at a speed of 1500 rpm for 10 seconds, then ...

Embodiment 2

[0031] Embodiment 2 (molar composition is Au: 1.2mol%, Pb (Zr 0.4 Ti 0.6 )O 3 :98.8mol%)

[0032] Step 1: Prepare the solution

[0033] With water, acetic acid and isopropanol as solvent, chloroauric acid, lead acetate, zirconium n-propoxide and titanium isopropoxide as solute, according to Pb:Ti:Zr molar ratio is 5:3:2, according to Au:Pb( Zr 0.4 Ti 0.6 )O 3 The mol ratio is 0.012:1, take by weighing chloroauric acid, lead acetate, zirconium n-propoxide and titanium isopropoxide, add water, acetic acid and isopropanol respectively with the concentration standard of 0.4mol / L, then carry out at room temperature Stir until the chloroauric acid, lead acetate, zirconium n-propoxide and titanium isopropoxide are all dissolved to obtain a light yellow transparent solution;

[0034] Step 2: Preparation of film material

[0035] (1) Using Pt / Ti / SiO 2 / Si(100) substrate. Drop the solution prepared in step 1 onto the substrate for spin coating at a speed of 1500 rpm for 10 sec...

Embodiment 3

[0040]Embodiment 3 (molar composition is Au:1.2mol%, PbTiO 3 :98.8mol%)

[0041] Step 1: Prepare the solution

[0042] With water, acetic acid and isopropanol as solvent, chloroauric acid, lead acetate, titanium isopropoxide as solute, according to Au:PbTiO 3 The molar ratio is 0.012:1, take by weighing chloroauric acid, lead acetate, titanium isopropoxide, add water, acetic acid and isopropanol respectively with the concentration standard of 0.4mol / L, then stir at room temperature, stir until chlorine Auric acid, lead acetate, and titanium isopropoxide are all dissolved until a light yellow transparent solution is obtained;

[0043] Step 2: Preparation of film material

[0044] (1) Using Pt / Ti / SiO 2 / Si(100) substrate. Drop the solution prepared in step 1 onto the substrate for spin coating at a speed of 1500 rpm for 10 seconds, then increase the speed to 4000 rpm for 40 seconds to obtain a raw material film;

[0045] (2) Dry the raw film at 120°C for 10 minutes, therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com