Diamond substrate-based gallium nitride high-electron-mobility transistor and preparation method thereof

A high electron mobility, gallium nitride-based wafer technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of difficult growth, poor material quality, large dislocation density, etc. Wrinkled or broken, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention is based on a diamond substrate gallium nitride high electron mobility transistor and a preparation method thereof, comprising the following steps:

[0028] 1) Clean the silicon carbide-based gallium nitride wafer and the surface of the temporary slide with hydrochloric acid, rinse with deionized water, and then put it into a dryer for drying.

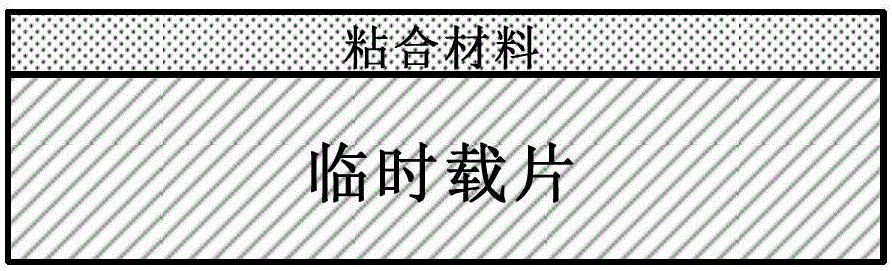

[0029] 2) Coating an adhesive material as a bonding material on the front side of the temporary carrier. The coating in the step 2) adopts the spin coating method, the rotating speed is 1000 rpm-3000 rpm, and the time is 30-60 seconds.

[0030] 3) Place the temporary slides face up on a hot plate and bake. The baking time in the step 3) is 2-5 minutes, and the temperature of the hot plate is 100-110 degrees Celsius.

[0031] 4) After the temporary carrier is naturally cooled at room temperature, the silicon carbide-based gallium nitride wafer and the temporary carrier are bonded facing each other. The bo...

Embodiment

[0039] The preparation method of the gallium nitride high electron mobility transistor based on the diamond substrate of the present invention is prepared by the following steps:

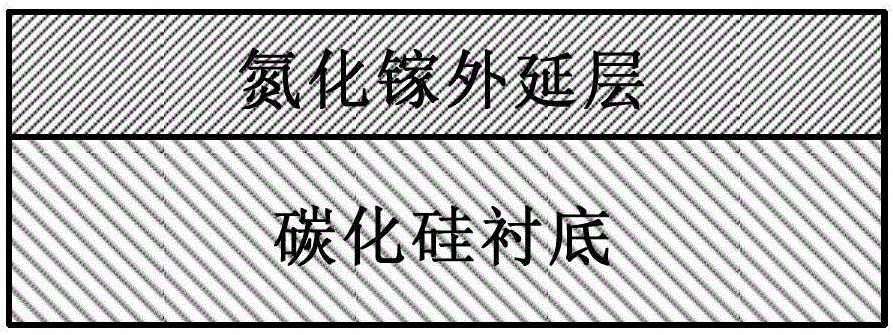

[0040] ①Preparation of samples: Soak GaN-on-SiC wafers and glass slides in dilute hydrochloric acid for 60 seconds, rinse with deionized water, blow dry with nitrogen, and finally dry the water thoroughly in an oven. Make sure the surface is clean and dry. Such as figure 1 , figure 2 shown.

[0041] ②Apply adhesive material on the front of the temporary slide: drop an appropriate amount of adhesive material on the front of the temporary slide, and spin coat at a rate of 1000-3000 rpm according to different thicknesses, and the spin coating time should not be less than 30 seconds After 10 minutes, place the temporary carrier coated with the adhesive material face up on the hot plate for pre-baking. The temperature of the hot plate is about 100-110 degrees Celsius, and the time is 2-5 minutes. If...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com