Quantum dot structure and manufacturing method, quantum dot light-emitting diode and manufacturing method

A technology of quantum dot luminescence and manufacturing methods, which is applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., and can solve problems such as unfavorable preparation of high-performance quantum dot light-emitting diodes, quantum dot collapse, and lattice mismatch. , to achieve the effect of ensuring monodispersity, eliminating compressive stress, and excellent structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

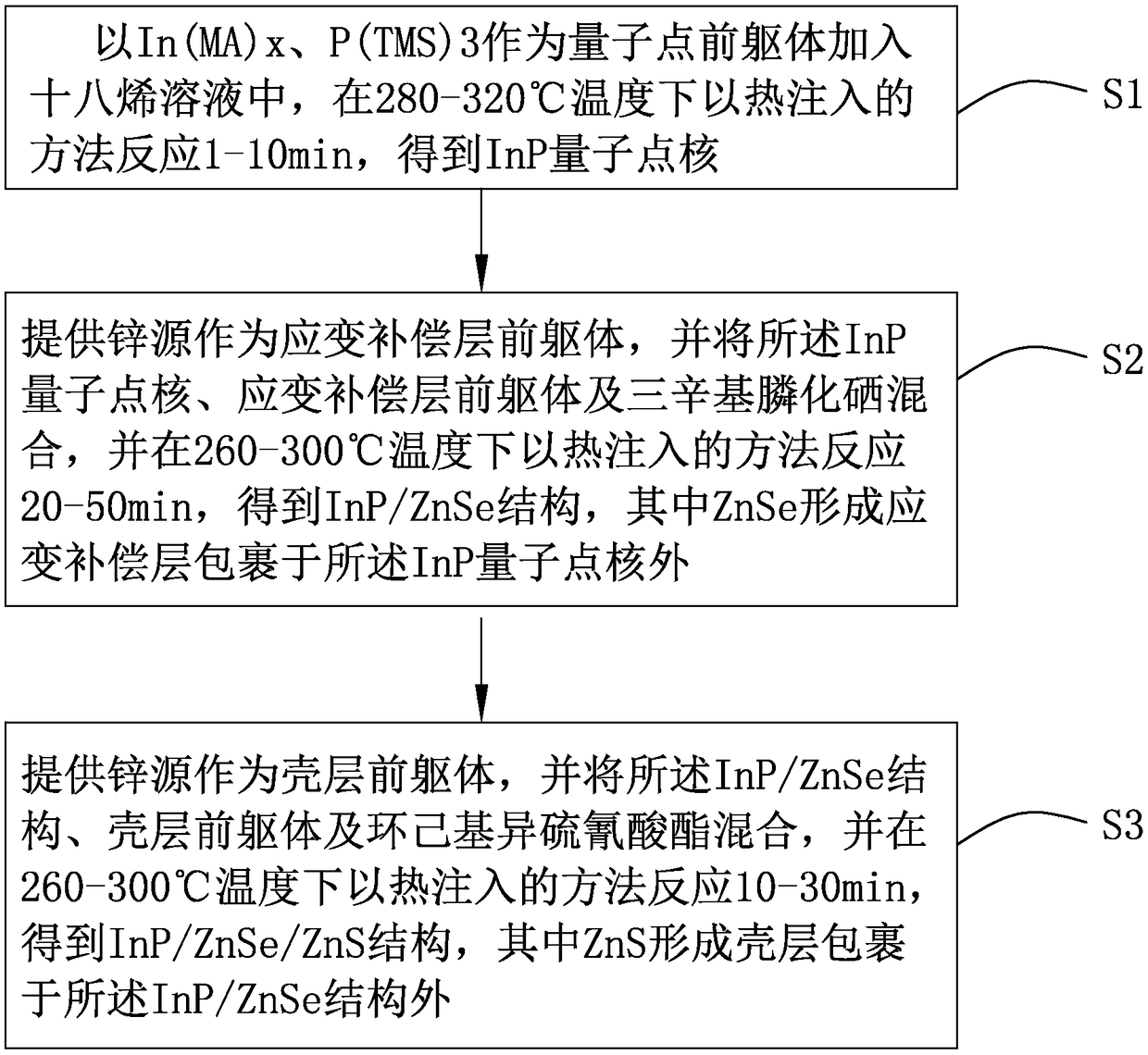

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

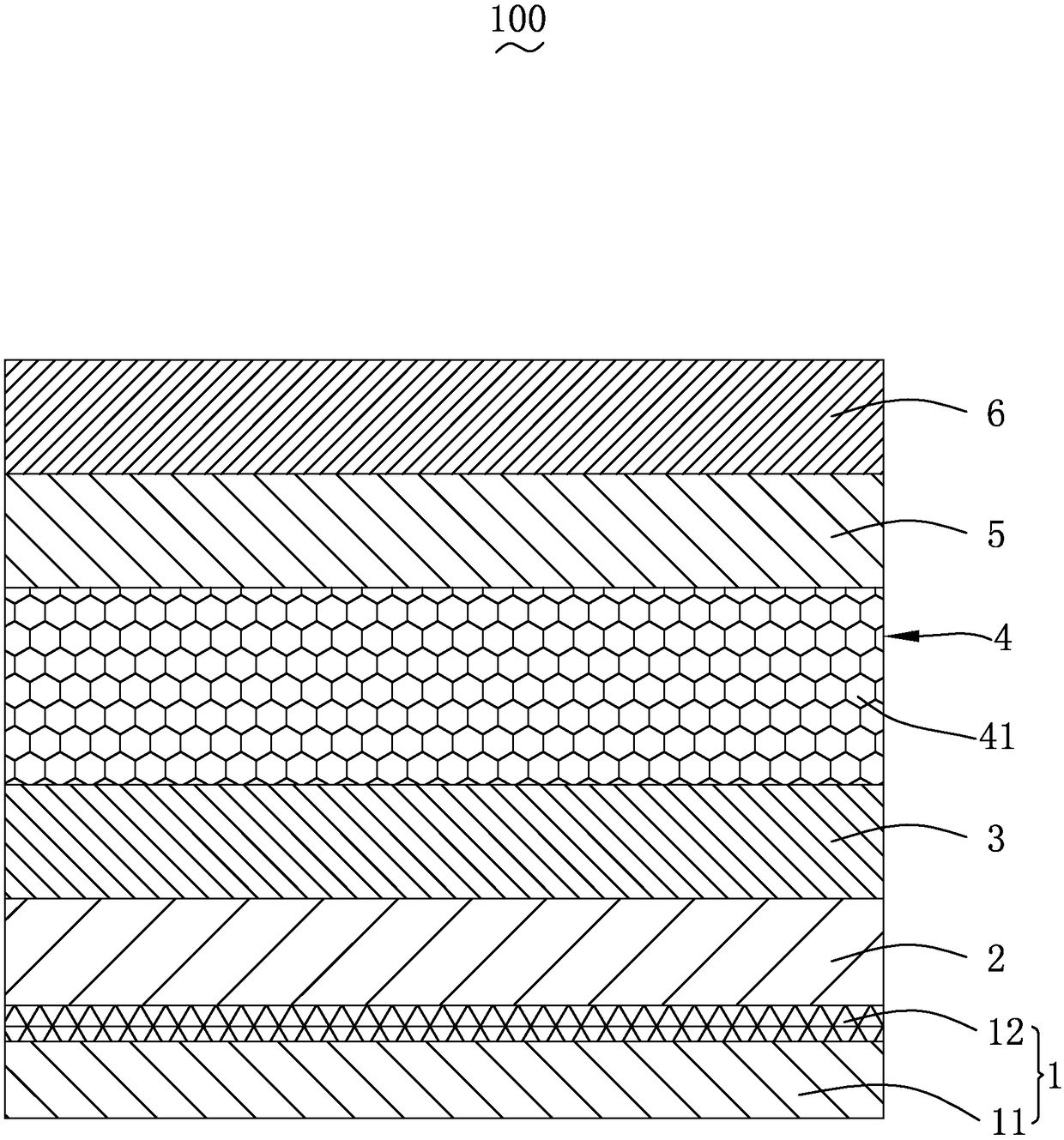

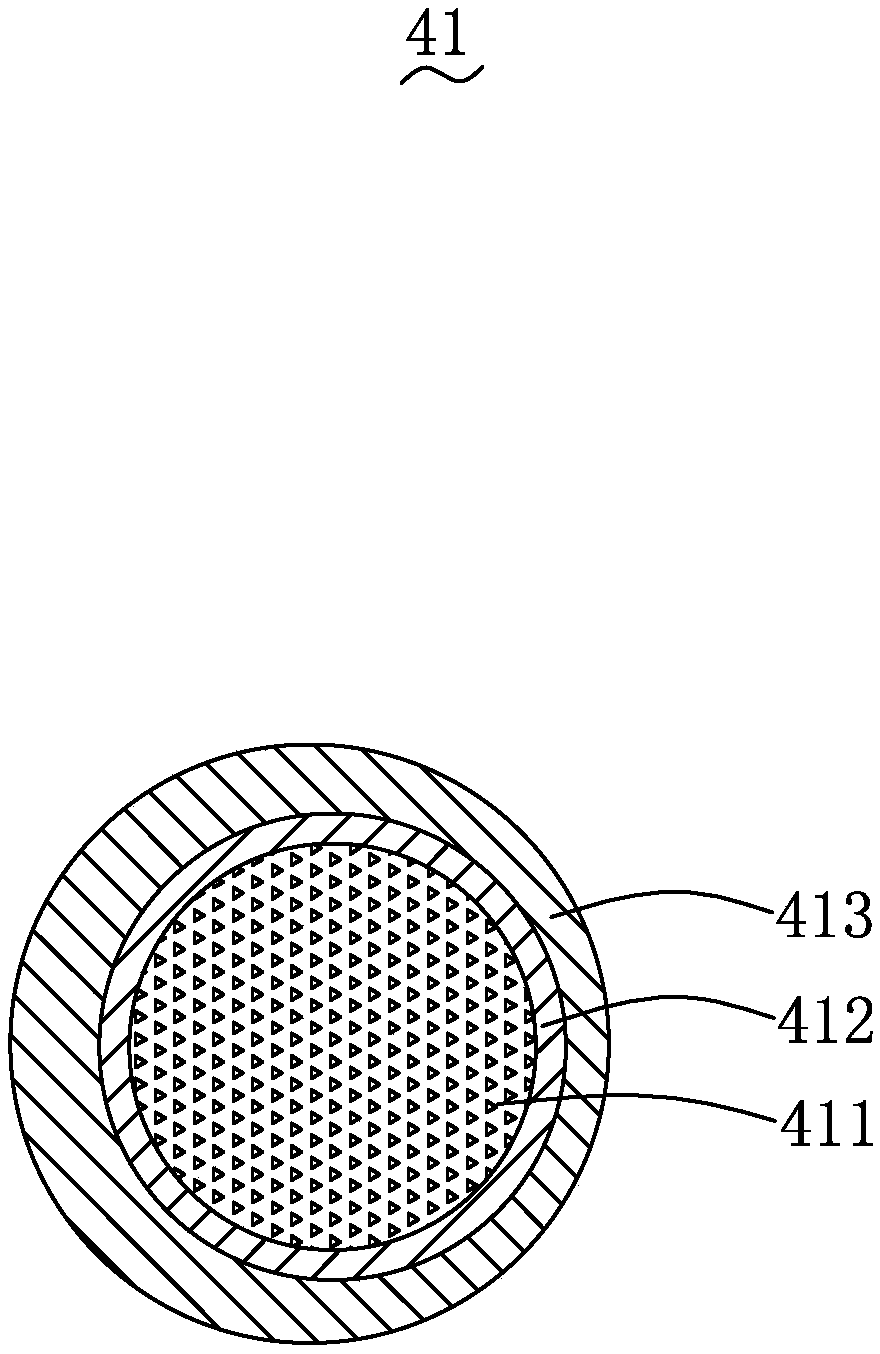

[0034] see figure 1 , is a schematic structural diagram of the quantum dot light-emitting diode provided by the present invention. The quantum dot light emitting diode 100 includes a substrate 1 , a hole injection layer 2 , a hole transport layer 3 , a quantum dot light emitting layer 4 , an electron transport layer 5 and a cathode 6 stacked in sequence.

[0035] The substrate 1 includes a substrate 11 and a conductive anode 12 deposited on the substrate 11 . The substrate 11 is a rigid substrate or a flexible substrate, wherein the rigid substrate is glass, silicon wafer or other rigid materials; the flexible substrate is a plastic substrate, aluminum foil, ultra-thin metal or ultra-thin glass. The conductive anode 12 is formed of ITO, graphene, indium gallium zinc oxide or other conductive materials, and is deposited on the surface of the substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com