Method for extracting xylan from wheat brans

A technology for wheat bran and xylan, which is applied to the field of xylan extraction from wheat bran, can solve the problems of residual xylan impurities, easily destroy xylan molecules, cannot meet needs, etc., and achieves good stability, High purity, suitable for accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

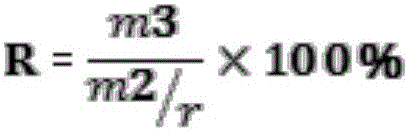

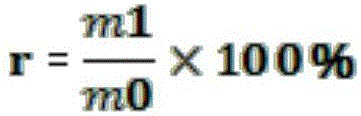

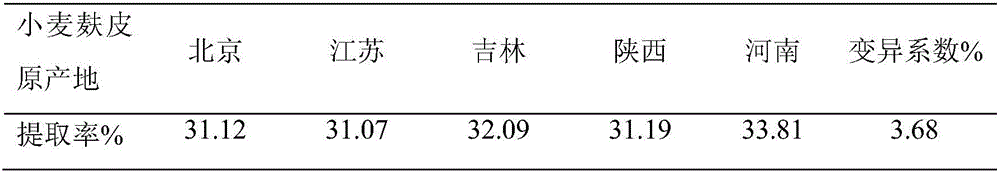

[0065] Example 1: Extraction and Extraction Rate Determination of Wheat Bran Xylan from Beijing, the Place of Origin

[0066]Wheat bran pretreatment: take 200-300g of wheat bran originating in Beijing, grind them, and pass through a 60-mesh sieve. Wrap the sieved wheat bran with fine-meshed cotton cloth, add trypsin, tie it tightly with a rubber band, wash it in hot water several times and wring it dry. Put the destarched bran into a 5L beaker, add 0.2% (w / v) EDTA solution, stir for 1h, filter with fine-pored cotton cloth (4.1), wash with distilled water and wring dry. Dry at 105°C for 4 hours, crush and save.

[0067] Extraction of xylan: Weigh an appropriate amount of pretreated wheat bran in alkali solution, add hydrogen peroxide solution, the ratio of solid to liquid is 1:50, add 4M NaOH solution to adjust the pH to alkaline while stirring magnetically, heat and shake in a constant temperature water bath overnight . Then use 10% hydrochloric acid to adjust the pH value ...

Embodiment 2

[0068] Embodiment 2: the wheat bran xylan extraction of place of origin Jiangsu

[0069] Except that the wheat bran was sourced from Jiangsu, other parameters were the same as in Example 1, and the extraction rate was determined to be 31.07% according to the above formula.

Embodiment 3

[0070] Example 3: Extraction of wheat bran xylan from Jilin, the place of origin

[0071] Except that the wheat bran was from Jilin, other parameters were the same as in Example 1, and the extraction rate was determined to be 32.09% according to the above formula.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com