New Denmark series sow lactation period breaking fodder and preparation method thereof

A technology for lactation and sows, which is applied in the field of crushed feed for Xindan sows during lactation and its preparation. It can solve problems such as insufficient limbs and hooves, slow postpartum recovery, and insufficient feed intake, so as to promote postpartum recovery and alleviate weight loss. , Improve the effect of subsequent litter size and utilization years

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

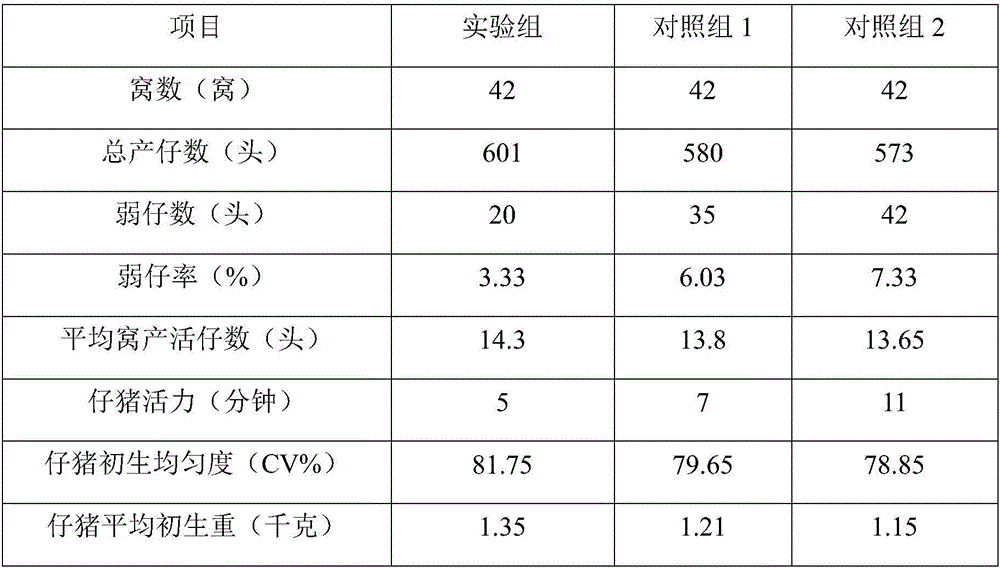

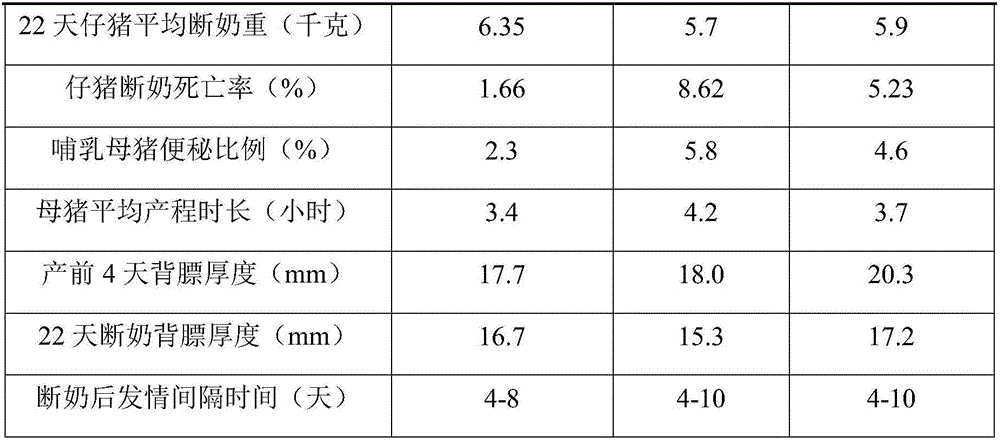

Examples

Embodiment 1

[0031] (1) A broken feed for sows of the Xindan system during lactation, consisting of the following raw materials in parts by weight:

[0032] 45 parts of corn, 5 parts of wheat, 5 parts of barley, 15 parts of soybean meal, 1 part of wheat bran, 5 parts of rice bran, 5 parts of corn DDGS, 1 part of puffed flaxseed, 2 parts of puffed soybean, 5 parts of fish meal, 2 parts of soybean hull, 0.5 part of soybean oil, 1 part of stone powder, 0.1 part of table salt, 0.1 part of baking soda, 1 part of sugar, 0.1 part of choline chloride, 1 part of amino acid, 0.1 part of vitamin C, 0.03 part of organic calcium HyD, 1 part of calcium hydrogen phosphate, 1 part of compound microecological preparation, 1 part of compound premix, 0.01 part of antioxidant, 1 part of beet pulp, 1 part of oat bran.

[0033] The preparation method of the puffed linseed is as follows: mix barley and linseed at 1:1, crush to 500-700 μm and then puff, wet puffing at a temperature of 110-130° C., and a preparati...

Embodiment 2

[0048] (1) A broken feed for sows of the Xindan system during lactation, consisting of the following raw materials in parts by weight:

[0049] 35 parts of corn, 10 parts of wheat, 10 parts of soybean meal, 3 parts of wheat bran, 10 parts of rice bran, 10 parts of corn DDGS, 2 parts of puffed flaxseed, 5 parts of puffed soybean, 3 parts of fish meal, 3 parts of soybean hull, 1 part of corn oil , 1.2 parts of stone powder, 0.2 parts of table salt, 0.2 parts of baking soda, 2 parts of sugar, 0.2 parts of choline chloride, 0.7 parts of amino acids, 0.2 parts of vitamin C, 0.01 parts of organic calcium HyD, 1.5 parts of calcium hydrogen phosphate, compound microecological preparation 0.7 part, 1 part of compound premix, 0.02 part of antioxidant, 1 part of apple pomace.

[0050] The preparation methods of the expanded linseed, expanded soybean and stone powder are the same as in Example 1.

[0051] The fish meal is imported steam fish meal, the crude protein content is higher than...

Embodiment 3

[0061] (1) A broken feed for sows of the Xindan system during lactation, consisting of the following raw materials in parts by weight:

[0062] 35 parts of corn, 5 parts of barley, 20 parts of soybean meal, 5 parts of wheat bran, 6 parts of rice bran, 7 parts of corn DDGS, 3 parts of puffed flaxseed, 3 parts of puffed soybean, 1 part of fish meal, 1 part of soybean hull, 1 part of soybean oil , 1 part of rice bran oil, 1 part of phospholipid oil, 2 parts of stone powder, 0.3 part of table salt, 0.3 part of baking soda, 3 parts of sugar, 0.3 part of choline chloride, 0.5 part of amino acid, 0.1 part of vitamin C, 0.02 part of organic calcium HyD , 0.5 parts of calcium hydrogen phosphate, 0.5 parts of compound probiotics, 1 part of compound premix, 0.03 parts of antioxidant, and 3 parts of beet pulp.

[0063] The preparation methods of the expanded linseed, expanded soybean and stone powder are the same as in Example 1.

[0064] The fish meal is imported steam fish meal, the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com