Light conversion film for green dye containing agglomeration-induced emission (AIE) properties

A technology of aggregation-induced luminescence and light-conversion film, which is applied in the field of green light dyes and flat-panel displays, and can solve problems such as unreported, increased display panel thickness, and insufficient film absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

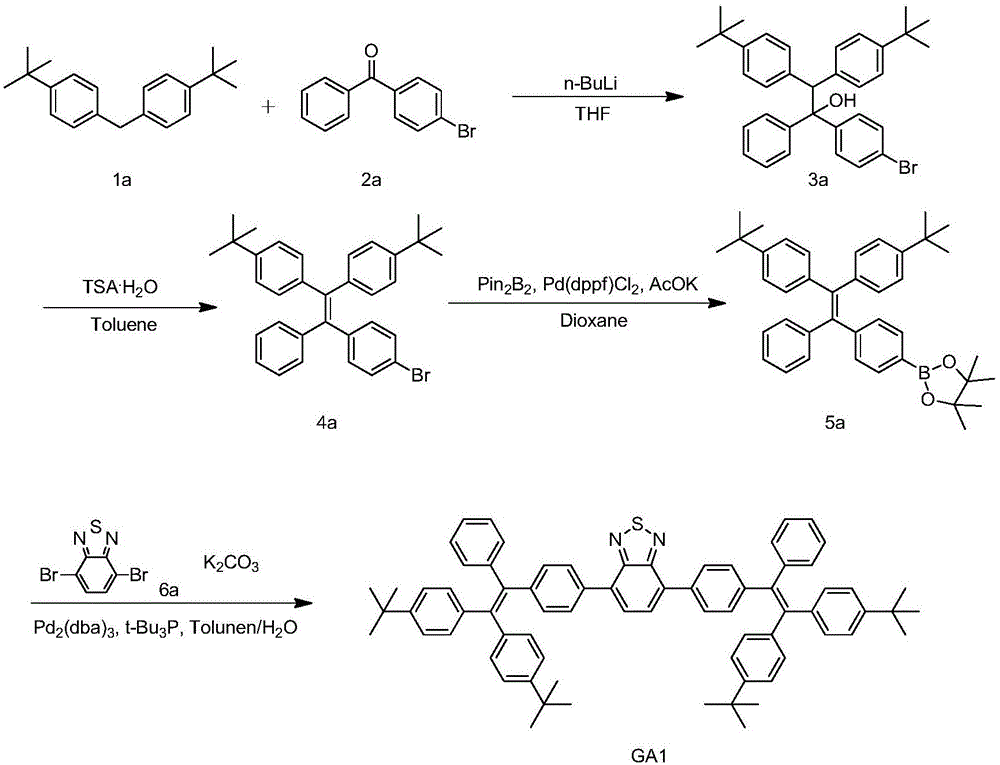

[0043] The synthesis of embodiment 1 green light dye GA1:

[0044]

[0045] (1) Synthesis of compound 3a

[0046] Synthesis steps: Dissolve compound 1a (commercially available) (5.61g, 20mmol) in anhydrous THF (100mL) under nitrogen protection, cool the reaction solution to 0°C, slowly add butyllithium (2.2M, 14mL) dropwise under stirring After the dropwise addition, continue stirring at low temperature for 1 h, then add compound 2a (commercially available) (10.45 g, 40 mmol) into the reaction solution, and continue stirring at low temperature for 1 h. The reaction solution was then warmed to room temperature and stirred overnight.

[0047] Post-reaction treatment: After the reaction, the reaction solution was poured into water, extracted with EA (100mL*3) and separated, the organic layers were combined, dried with anhydrous sodium sulfate, and evaporated to dryness under reduced pressure. The crude product was directly used in the next reaction without purification.

[...

Embodiment 2

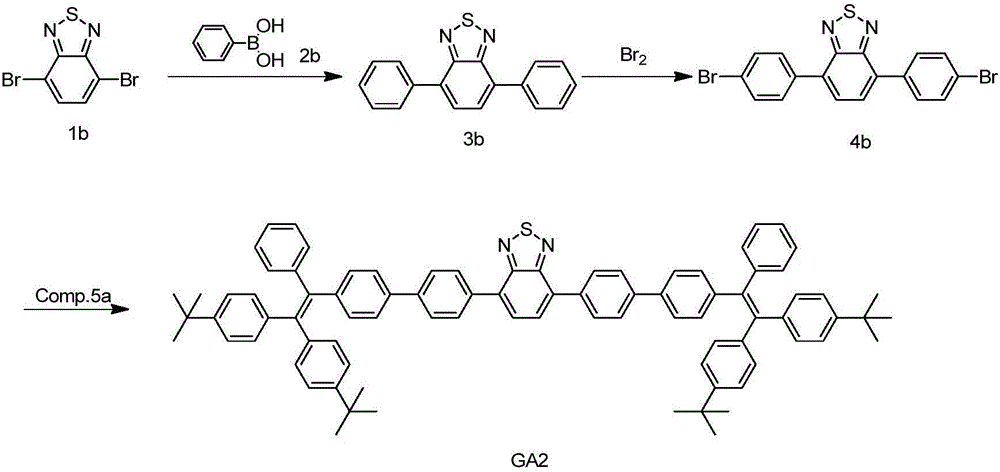

[0060] The synthesis of embodiment 2 green light dye GA1:

[0061]

[0062] (1) Synthesis of compound 3b

[0063] Synthetic steps: add compound 6a (commercially available) (2.93g, 10mmol) to 250mL reaction flask, compound 2b (commercially available) (2.68g, 22mmol), tetrakistriphenylphosphine palladium (1.15g, 5%), K 2 CO 3 (4.14g, 30mmol), toluene (100mL) and water (20mL). Nitrogen was evacuated 3 times, heated up to 80° C., kept at this temperature, and reacted for 8 hours. TLC detected that the reaction of compound 6a was complete.

[0064] Post-reaction treatment: Stop heating, lower the temperature to 20°C, pour the reaction liquid into water, extract and separate the liquids with EA (100 mL*3), combine the organic layers, dry with anhydrous sodium sulfate, and evaporate to dryness under reduced pressure. The crude product was subjected to column chromatography to obtain pale yellow compound 3b (2.3g, yield 79.8%). 1 H NMR (400 MHz, CHLOROFORM-d) δ = 7.97 (d, J = 7...

Embodiment 3

[0073] The photophysical property test of embodiment 3 green light dyes GA1 and GA2:

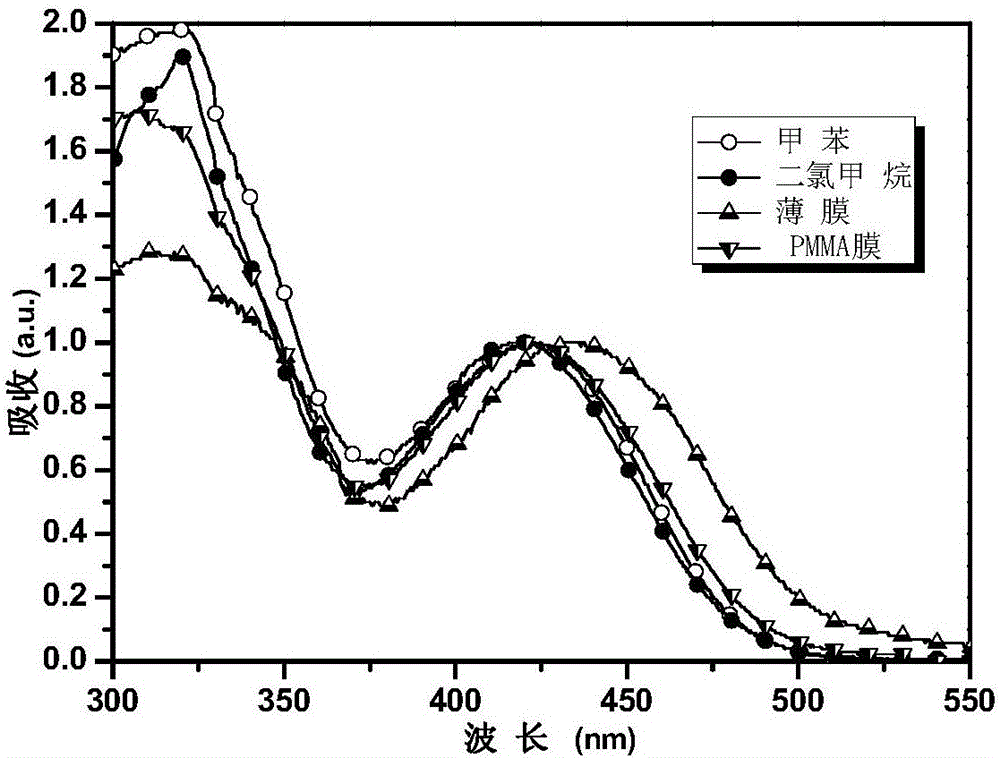

[0074] The test of photophysical properties of green light dyes GA1 and GA2 in solution is to dissolve the corresponding dyes in toluene or dichloromethane, and the concentration of the solution is 1×10 -5 mol / L, the dye-based CCF film was prepared by dissolving the dye and the corresponding proportion of PMMA in toluene, and then drying it. The photophysical properties of the dye film were measured after the dye was dissolved in THF and then spin-coated to prepare the film. The effect of CCF films prepared with GA1 and GA2 on background blue light (λ max ≈450nm) has good absorption, and the emitted light is green light. The fluorescence of GA1 and GA2 in solution is weak (QY<50%), and they show strong fluorescence after being made into solid or PMMA film, with With typical AIE properties, the present invention applies AIE dye molecules to organic light conversion film materials for the fir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap