Efficient separation and purification process for bioleaching solution with low-content nickel and cobalt

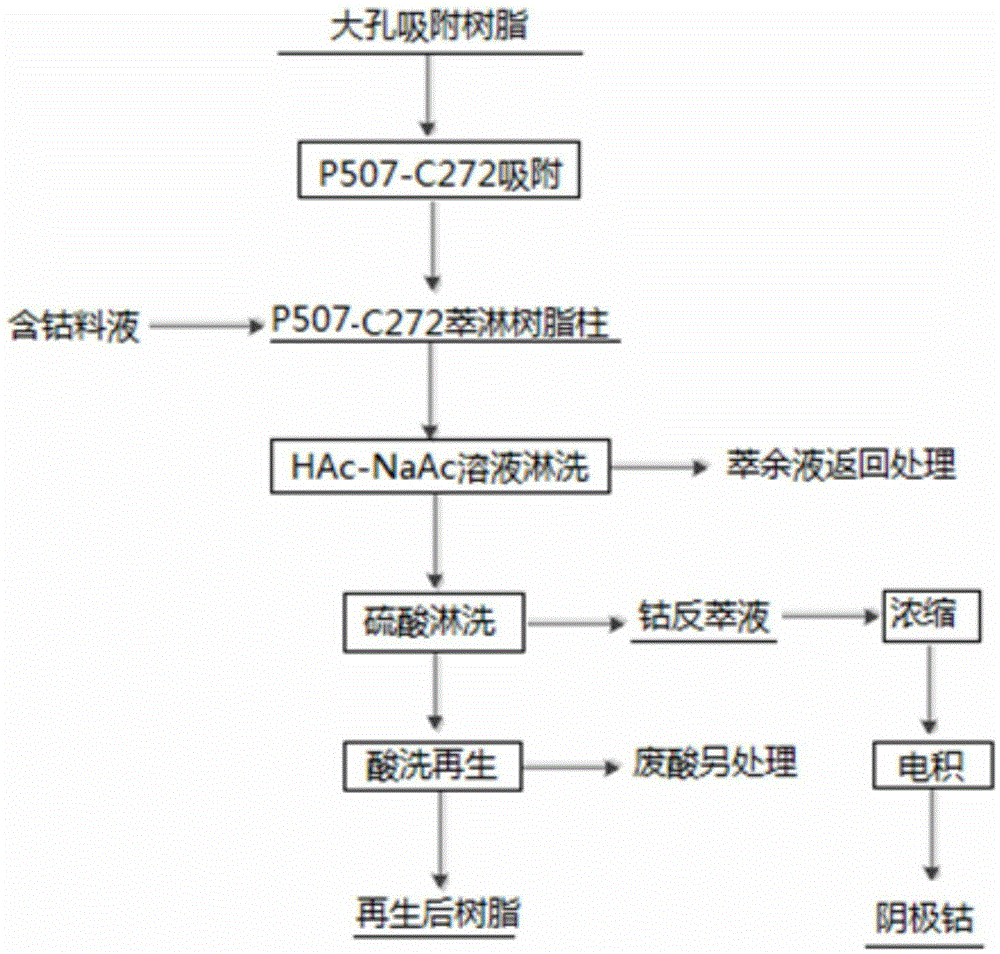

A bioleaching, purification and separation technology, applied in the direction of improving process efficiency, can solve the problems of many extraction stages, low separation efficiency, poor selectivity, etc., and achieve good mass transfer effect, large separation coefficient, and large cobalt loading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Since a nickel-cobalt ore is a low-grade complex and refractory sulfide ore, the content of valuable metal nickel-cobalt in the bioleach solution obtained by bioheap leaching is low, which makes purification and separation difficult. The traditional extraction and separation efficiency is low and the process is complicated, which seriously affects Comprehensive recovery of nickel and cobalt.

[0025] As shown in Table 1, it is the composition analysis of the nickel-cobalt bioleach solution after the nickel-cobalt ore is bioheap leached to remove iron.

[0026] Table 1

[0027] element co Ni Cu Fe Ca Mg Contentmg / L 198 1840 3.22 0.39 390 14760

[0028] Adopting the process of the present invention to separate and purify the biological leachate, the specific steps are:

[0029] (1) Preparation of double extractant extraction resin: select the macroporous adsorption resin of HZ818 (grain grade 20-60 mesh) as the support, and use the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com