Flexible solar cell array suitable for near space super long endurance aircraft

A flexible solar cell and near space technology, applied in the field of flexible solar cell arrays, can solve problems such as heavy weight, inflexibility, and difficulty in meeting areal density requirements, achieve no impact on performance, strong environmental resistance, and improve flatness and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

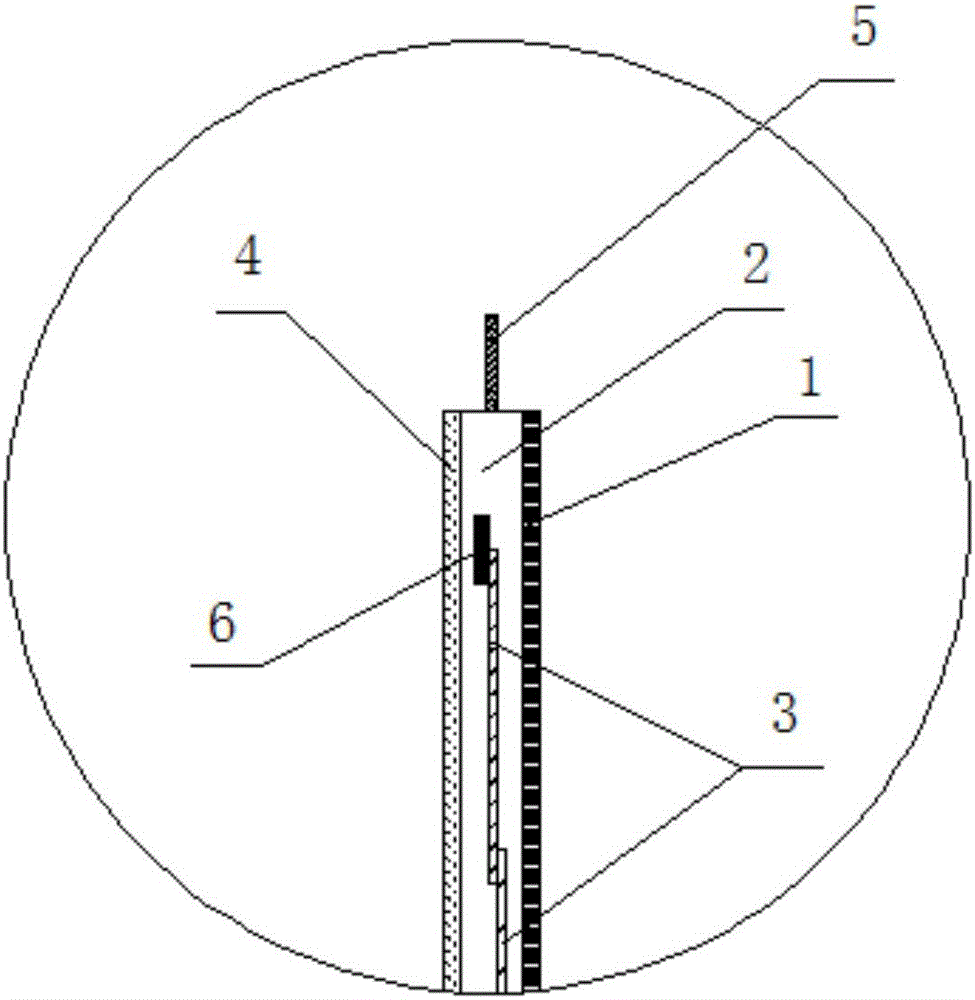

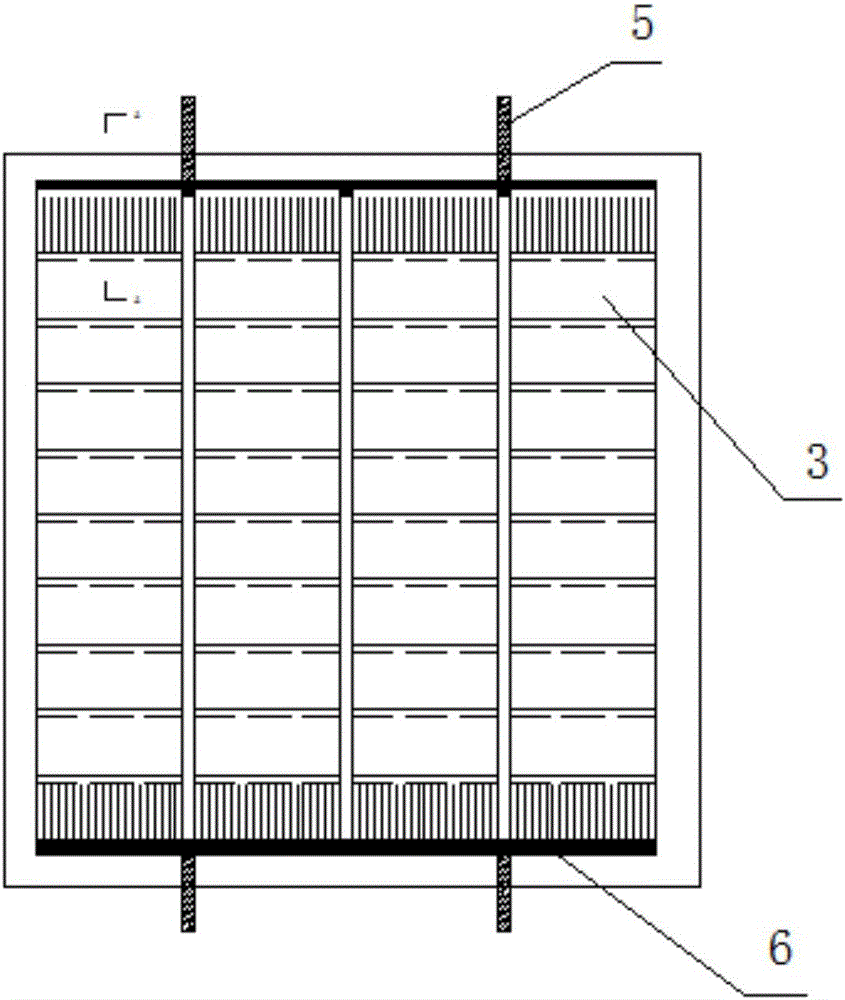

[0034] A flexible solar cell array suitable for ultra-long-endurance aircraft in near space. From top to bottom, transparent fluoropolymer film, polyolefin film, battery string, polyolefin film, transparent or white polymer film Sequential lamination, the battery string adopts flexible multi-junction GaAs battery as the power generation unit, and the overlapping contact method of the battery is adopted to realize the series and parallel connection between the batteries. Made of fluorine-containing polymer film, the lower surface is encapsulated with transparent or white polymer film, and the adhesive is hot-melt polyolefin film, which is polymerized with fluorine-containing transparent polymer film and / or white polymer film on the front and back sides of the battery string respectively The material film is hot-melt bonded, and the flexible solar cell array is laminated at one time at high temperature.

[0035] Flexible solar arrays for ultra-long-endurance vehicles in near spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com