Diluent for live vaccine for hog cholera

A technology of live swine fever vaccine and diluent, which is applied in the field of diluent for live swine fever vaccine, can solve the problems of reducing the immune effect of live swine fever vaccine, the uniformity of immune titers is not high, and the difference between vaccines is large, so as to improve the overall Immunization levels, reduced batch-to-batch variability, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

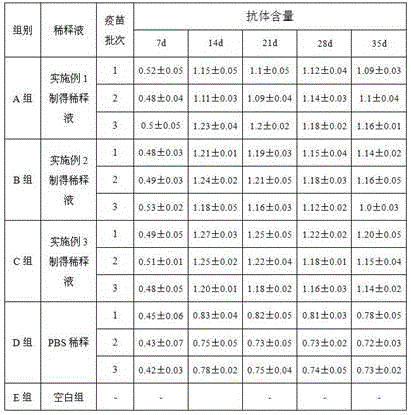

Examples

Embodiment 1

[0024] 1. Prepare Agaricus blazei polysaccharide, comprising the following steps:

[0025] (1) Grinding Agaricus blazei to obtain Agaricus blazei powder, according to the ratio of material to liquid: 1:70g / ml, add distilled water to Agaricus blazei powder and adjust the pH to 7.0;

[0026] (2) Microwave extraction: set the microwave power to 500W, extract for 8 minutes, and collect the extract. The microwave extraction process is intermittent microwave extraction, that is, after 2 minutes of extraction, pause for 1 minute, and at the same time add the lost water to keep the volume of the extract relatively constant. ;

[0027] (3) Repeat step (2) to collect the extract;

[0028] (4) Mix the filtrate obtained in steps (2) and (3), concentrate to 1 / 4 volume with a rotary evaporator, add 80% ethanol, let stand at 4 °C for 12 h, and collect the precipitate by centrifugation;

[0029] (5) The precipitate obtained in step (4) is washed with absolute ethanol and acetone in sequence...

Embodiment 2

[0039] 1. Prepare Agaricus blazei polysaccharide, comprising the following steps:

[0040] (1) Grind Agaricus blazei to obtain Agaricus blazei powder, according to the ratio of material to liquid: 1:80g / ml, add distilled water to Agaricus blazei powder to adjust the pH to 7.0;

[0041] (2) Microwave extraction: set the microwave power to 700W, extract for 10 minutes, and collect the extract. The microwave extraction process is intermittent microwave extraction, that is, after 2 minutes of extraction, pause for 1 minute, and at the same time add the lost water to keep the volume of the extract relatively constant. ;

[0042] (3) Repeat step (2) to collect the extract;

[0043] (4) Mix the filtrate obtained in steps (2) and (3), concentrate to 1 / 4 volume with a rotary evaporator, add 80% ethanol, let stand at 4 °C for 12 h, and collect the precipitate by centrifugation;

[0044] (5) The precipitate obtained in step (4) is washed with absolute ethanol and acetone in sequence, a...

Embodiment 3

[0054] 1. Prepare Agaricus blazei polysaccharide, comprising the following steps:

[0055] (1) Grind Agaricus blazei to obtain Agaricus blazei powder, add distilled water to Agaricus blazei powder according to the material-to-liquid ratio of 1:90g / ml and adjust the pH to 7.0;

[0056](2) Microwave extraction: set the microwave power to 600W, extract for 12 minutes, and collect the extract. The microwave extraction process is intermittent microwave extraction, that is, after 2 minutes of extraction, pause for 1 minute, and at the same time add the lost water to keep the volume of the extract relatively constant. ;

[0057] (3) Repeat step (2) to collect the extract;

[0058] (4) Mix the filtrate obtained in steps (2) and (3), concentrate to 1 / 4 volume with a rotary evaporator, add 80% ethanol, let stand at 4 °C for 12 h, and collect the precipitate by centrifugation;

[0059] (5) The precipitate obtained in step (4) is washed with absolute ethanol and acetone in sequence, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com