Aromatic polyamide composite RO (reverse osmosis) membrane grafted with fluorocarbon materials and aminoglycoside antibiotics as well as preparation method

A technology of aminoglycosides and aromatic polyamides, applied in chemical instruments and methods, reverse osmosis, semi-permeable membrane separation, etc., to achieve excellent anti-pollution performance, low cost, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

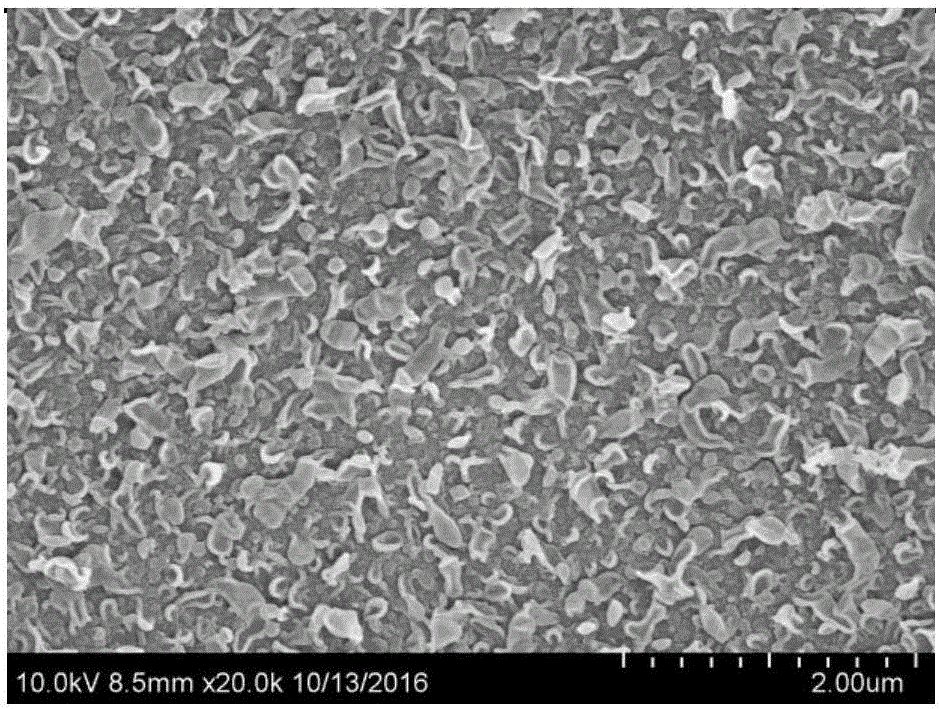

[0021] Prepare a solution containing hexafluorobutyl methacrylate with a molar concentration of 0.05mol / L and bromo-3,4-dimethoxyacetophenone initiator solution with a molar concentration of 0.001mol / L; immerse the surface of the nascent reverse osmosis membrane in the above After being immersed in the solution for 5 seconds, take out the reverse osmosis membrane and initiate grafting under ultraviolet light for 10 seconds; then immerse the surface of the reverse osmosis membrane in a tobramycin solution with a molar concentration of 0.005 mol / L for 1 minute, and finally dry the membrane to obtain Polyhexafluorobutyl methacrylate and tobramycin modified aromatic polyamide composite reverse osmosis membrane. Electron microscope pictures such as image 3 shown.

[0022] At 1.55MPa and 25°C, the initial permeate flux and salt rejection rate of polyhexafluorobutyl methacrylate and tobramycin modified aromatic polyamide composite reverse osmosis membrane were tested by using 2000m...

Embodiment 2

[0028]Prepare a solution containing octafluoropentyl methacrylate with a molar concentration of 0.2mol / L and bromo-3,4-dimethoxyacetophenone initiator solution of 0.1mol / L; immerse the surface of the nascent reverse osmosis membrane in the above-mentioned In the solution for 30s, take out the membrane and initiate grafting under a UV lamp for 5min; then immerse the surface of the reverse osmosis membrane in kanamycin with a molar concentration of 0.1mol / L for 20s, and finally dry the membrane to obtain methacrylic acid Aromatic polyamide composite reverse osmosis membrane modified by octafluoropentyl ester and kanamycin. Electron microscope pictures such as Figure 4 shown.

[0029] At 1.55MPa and 25°C, the initial permeate flux and salt rejection rate of the aromatic polyamide composite reverse osmosis membrane modified by octafluoropentyl methacrylate and kanamycin were tested by using 2000mg / L sodium chloride aqueous solution, respectively. 45L / (m 2 • h) and 99.1%.

[0...

Embodiment 3

[0035] Prepare a solution containing trifluoroethyl methacrylate with a molar concentration of 0.1mol / L and bromo-3,4-dimethoxyacetophenone initiator solution at 0.05mol / L; immerse the surface of the nascent reverse osmosis membrane in the above After 5 minutes in the solution, take out the membrane and initiate grafting under ultraviolet light for 1 minute; then immerse the surface of the reverse osmosis membrane in gentamicin with a molar concentration of 0.008mol / L for 5 minutes, and finally dry the membrane to obtain methacrylic acid Aromatic polyamide composite reverse osmosis membrane modified by trifluoroethyl ester and gentamicin. Electron microscope pictures such as Figure 5 shown.

[0036] At 1.55MPa and 25°C, the initial permeate flux and salt rejection rate of trifluoroethyl methacrylate and gentamicin modified aromatic polyamide composite reverse osmosis membrane were tested by using 2000mg / L sodium chloride aqueous solution as 55L / (m 2 • h) and 99.1%.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salt rejection | aaaaa | aaaaa |

| Salt rejection | aaaaa | aaaaa |

| Salt rejection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com