Perfluoro polyether type fluorocarbon surfactant as well as preparation method and application thereof

A perfluoropolyether, fluorocarbon surface technology, applied in biochemical equipment and methods, DNA preparation, chemical instruments and methods, etc., can solve the problems of weak hydroxyl reaction activity and low reaction yield, and achieve low cost and purification. Simple, easy-to-synthesize effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A perfluoropolyether fluorocarbon surfactant is synthesized and prepared according to the following route:

[0044]

[0045] (1) Acylation.

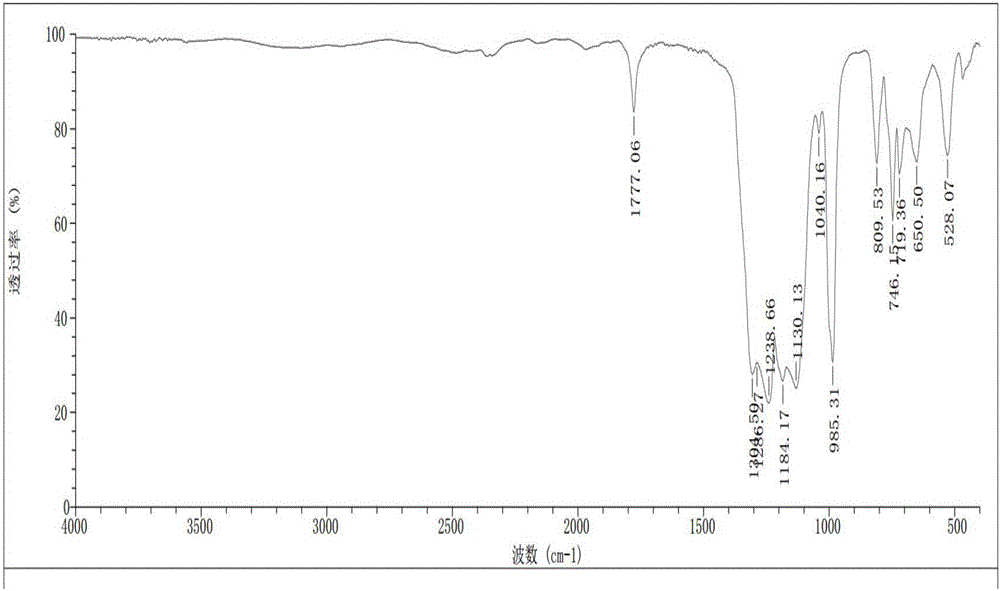

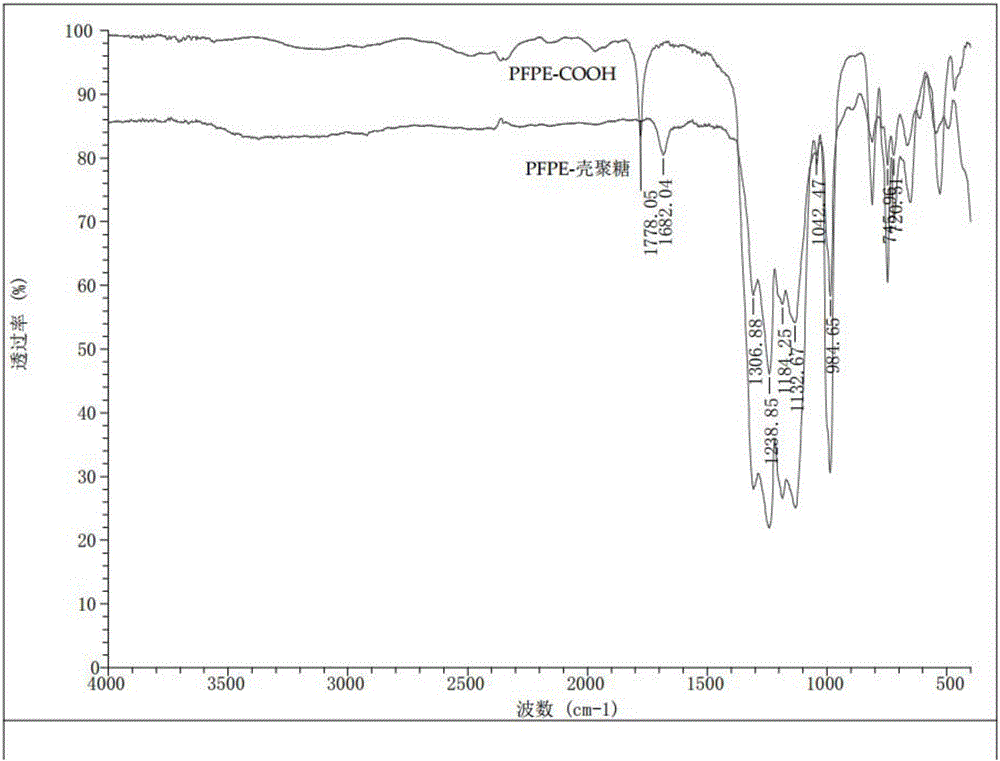

[0046] First weigh 0.729g of carboxyl perfluoropolyether (PFPE-COOH) (purchased from DuPont, Krytox157FSH, average molecular weight is 6500) dissolved in 50ml of solvent fluorine oil (purchased from 3M company, model is Novec TM 7100), then add thionyl chloride 0.16ml (about 20 equivalents), and stir and reflux overnight (about 12h) under the protection of nitrogen.

[0047] After the mixture was cooled to room temperature, it was concentrated by distillation with a rotary evaporator to obtain acylated perfluoropolyether (PFPE-COCl), and the solvent and excess thionyl chloride were removed by vacuuming.

[0048] (2) Reaction.

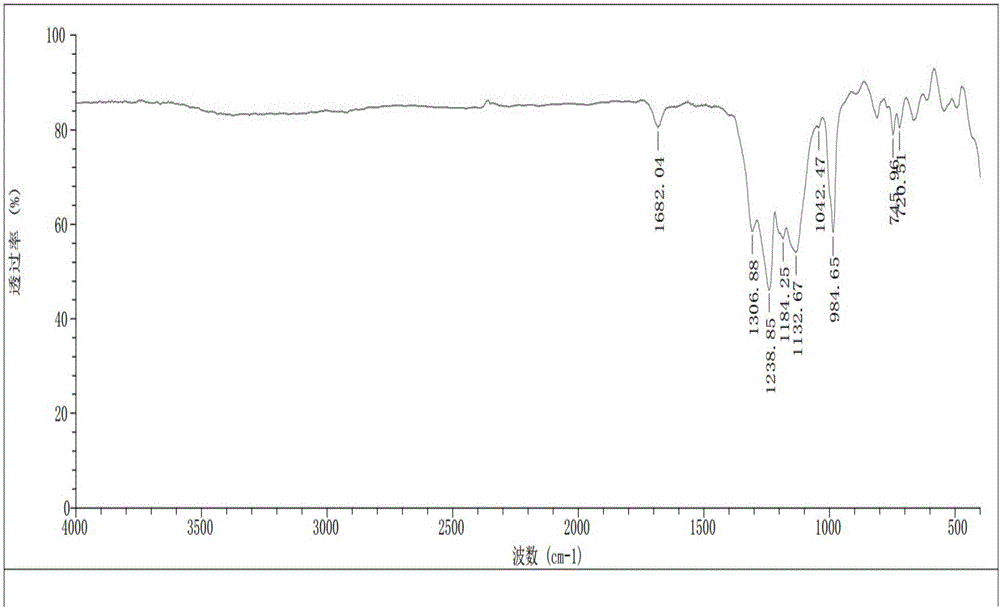

[0049] Dissolve PFPE-COCl in 80ml of (Novec TM 7100: trifluorotoluene=5: 3) in the reaction solvent, under nitrogen protection, add 0.729g chitosan (this chitosan is 1 times of PFPE-COOH quality, deac...

Embodiment 2

[0056] A droplet forming oil, the fluorosurfactant prepared in Example 1 was dissolved in 3M in an amount of 2% by mass TM Novec TM 7500 fluorine oil, that is.

Embodiment 3

[0058] Application of the droplet forming oil of Example 2 in the microdropletization process of PCR amplification.

[0059] PCR oil phase: the droplet forming oil in Example 2 was used as the PCR oil phase.

[0060] PCR water phase: The PCR water phase includes (40-60) 2X Buffer, (0.02-0.06) gDNA (20ng / μL), (0.006-0.01) Taq (5U / μL), (0.02-0.06) Primer-F ( 10 μM), (0.02-0.06) Primer-R (10 μM), (0.01-0.03) Probe (10 μM). The above solutions were uniformly mixed sequentially, and ultrapure water was added dropwise and mixed uniformly as the reaction aqueous phase for later use.

[0061] Take 7 times the volume of the oil phase and 2 times the volume of the water phase to generate well-uniform water-in-oil droplets (20 μm-100 μm) in the microfluidic chip, such as Figure 4 shown.

[0062] Then PCR amplification thermal cycling experiments were performed. The droplet morphology was observed under the microscope before thermal cycling of PCR amplification, such as Figure 5 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com