Preparation method and application of attapulgite/molybdenum sulfide composite material

A technology of attapulgite and composite materials, applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc., can solve problems such as low utilization rate of visible light, and achieve the effects of avoiding curling and breaking, promoting transfer, and avoiding compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 0.97g of sodium molybdate, 1.5g of thioacetamide and 0.21g of attapulgite into 60ml of deionized water for ultrasonication and stir for 30min, transfer the resulting mixture to a reaction kettle at 240°C for 24h, filter and filter cake After fully washing with water and alcohol, dry at 100°C for 24 hours to obtain the attapulgite / molybdenum sulfide composite material.

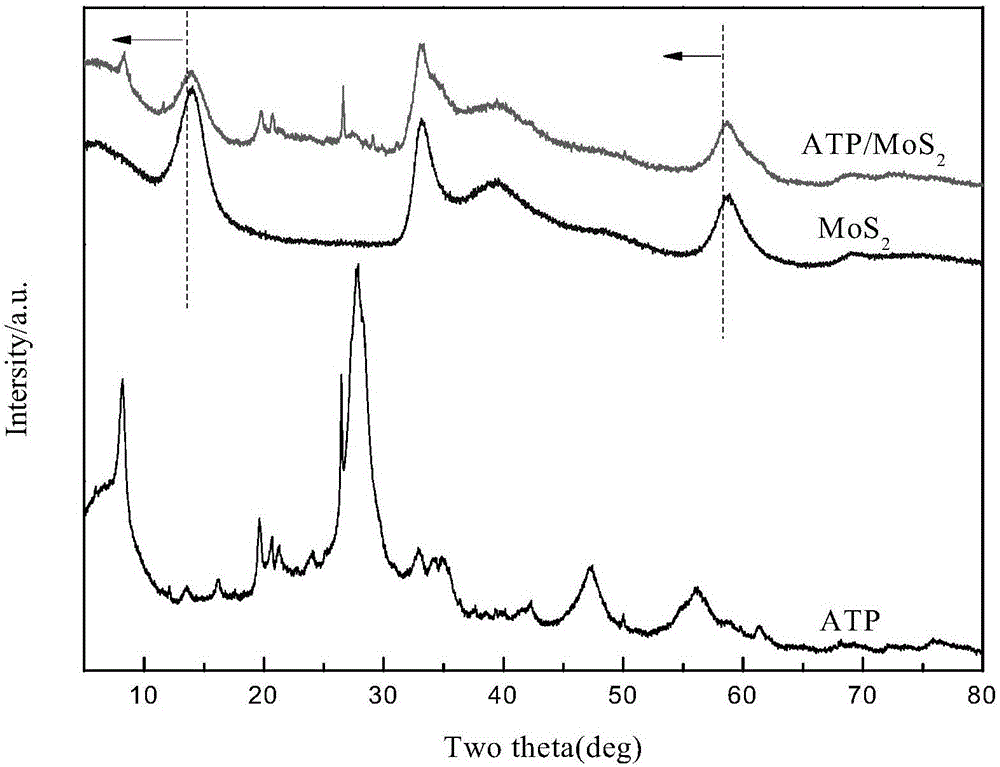

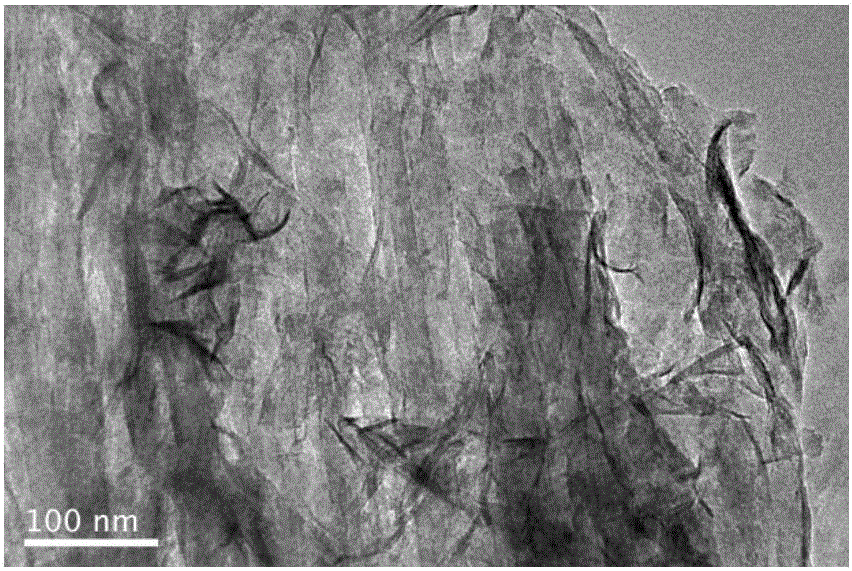

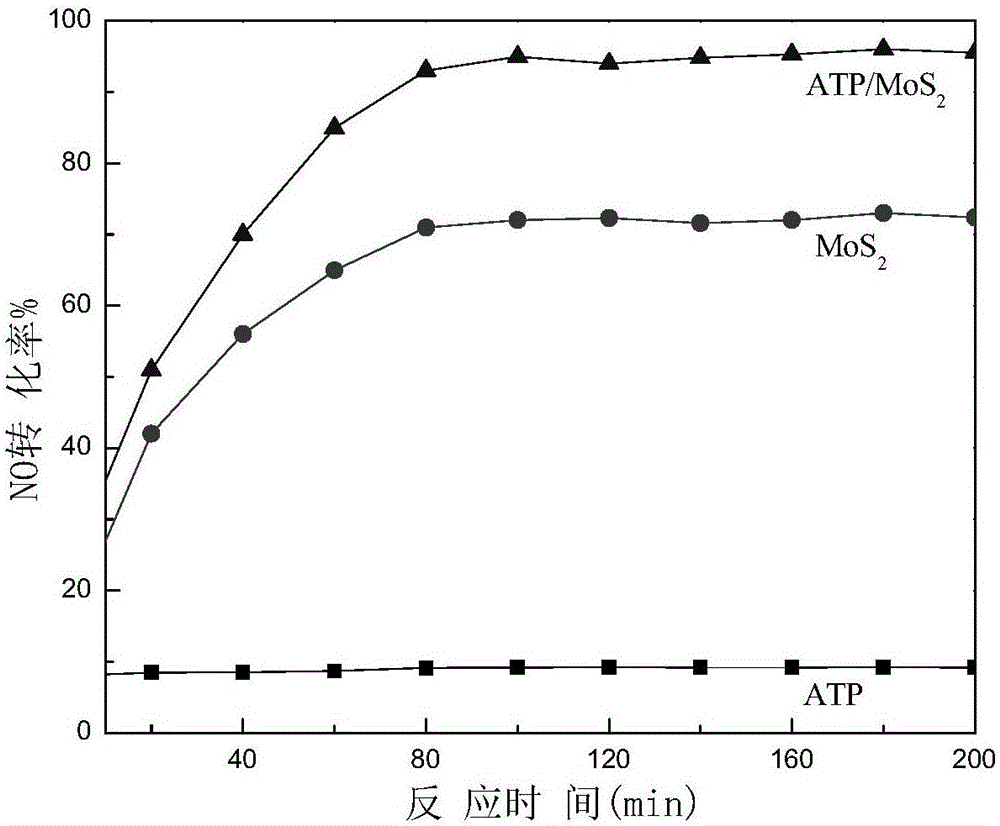

[0021] Carry out X-ray powder diffraction experiment to the attapulgite / molybdenum sulfide composite material prepared in the present embodiment, and observe its morphology and structure under the transmission electron microscope, it and the XRD pattern of attapulgite, molybdenum sulfide are as follows figure 1 As shown: in the XRD of the composite material, the characteristic diffraction peaks of attapulgite and molybdenum sulfide appeared, and the respective peak intensities were all reduced, indicating that attapulgite and molybdenum sulfide were successfully composited; in addition, ATP / MoS 2 Med...

Embodiment 2

[0026] Add 0.97g of sodium molybdate, 1.5g of thioacetamide and 0.08g of attapulgite into 60ml of deionized water for ultrasonication and stir for 30min, transfer the resulting mixture to a reaction kettle at 180°C for 16h, filter and filter cake After fully washing with water and alcohol, dry at 60°C for 12 hours to obtain the attapulgite / molybdenum sulfide composite material, and the subsequent detection is as in Example 1.

Embodiment 3

[0028] Add 0.97g of sodium molybdate, 1.5g of thioacetamide and 0.32g of attapulgite into 60ml of deionized water for ultrasonication and stir for 30min, transfer the resulting mixture to a reaction kettle at 200°C for 20h, filter, and filter cake After being fully washed with water and alcohol, dried at 80°C for 16 hours to obtain the attapulgite / molybdenum sulfide composite material, the subsequent detection is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com