Method for improving catalytic selectivity of supported catalyst and application thereof

A supported catalyst and selectivity technology, applied in catalytic reactions, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as incompatibility between conversion rate and selectivity, difficulty in ensuring active components, and decline in catalyst selectivity , to achieve the effect of improving molecular size selectivity and chemical reaction site selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Selective Catalytic Hydrogenation of Alkenes over Molecular Sieve Catalysts

[0019] Choose an aperture of A-type molecular sieves, Pt / molecular sieve supported catalysts were prepared by the traditional impregnation method. Before the reaction, the prepared catalyst was dried in a vacuum oven at 120° C. for 10 h. Weigh 20 mg of processed The molecular sieve catalyst was placed in a 12ml glass bottle, 3ml of ethyl acetate, 62.5 μL of n-hexene and 65 μL of cis-cyclooctene were added, and sealed with a silica gel stopper. Then use a vacuum pump to pump out the gas in the bottle, and inject pure hydrogen at the same time, and repeat the operation 5 times. After the mixture was ultrasonically dispersed for 10 min, the reaction was stirred at room temperature for 24 h.

Embodiment 2

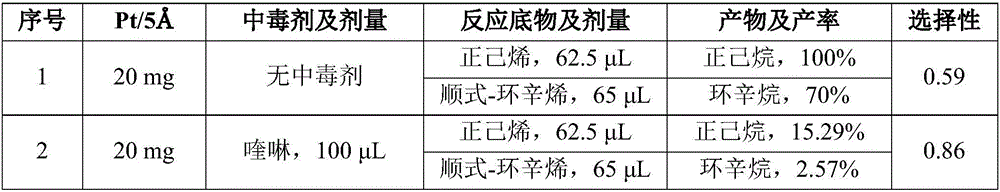

[0020] Example 2: Selective Catalytic Hydrogenation of Alkenes with Poisoned Pt / Molecular Catalyst

[0021] Take by weighing 20mg of processed in embodiment 1 The molecular sieve catalyst was placed in a 12ml glass bottle, 2ml of ethyl acetate and 100μL of poisoning agent quinoline were added, sealed with a silica gel stopper, the mixture was ultrasonically dispersed for 10min, and stirred at room temperature for 2h. Centrifuge, wash 3 times with ethyl acetate, dry, and place in a 12ml glass bottle. Add 3 mL of ethyl acetate, 62.5 μL of n-hexene, and 65 μL of cis-cyclooctene, and seal with a silicone stopper. Then use a vacuum pump to pump out the gas in the bottle, and inject pure hydrogen at the same time, and repeat the operation 5 times. After the mixture was ultrasonically dispersed for 10 min, the reaction was stirred at room temperature for 24 h. The reaction product yield and selectivity of comparative examples 1 and 2 are as shown in table 1.

[0022] Table 1 T...

Embodiment 3

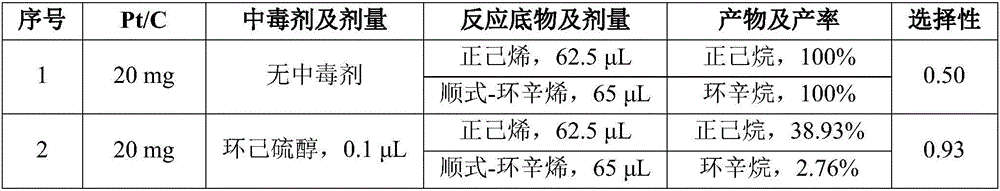

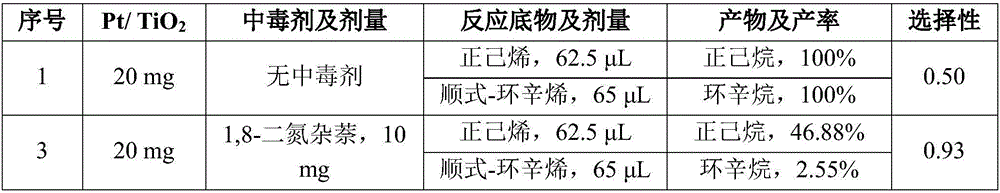

[0024] Example 3: Selective catalytic hydrogenation of olefins before and after Pt / C catalyst poisoning

[0025] According to the process of Examples 1 and 2, the catalyst carrier was replaced by activated carbon to carry out the Pt / C catalyst catalytic hydrogenation reaction, and the results are shown in Table 2.

[0026] Table 2Pt / C catalyst is used for the catalytic hydrogenation reaction result of n-hexene and cis-cyclooctene

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com