Two-dimensional material powder preparation method and two-dimensional material powder dispersion liquid preparation method

A two-dimensional material and dispersion liquid technology, applied in chemical instruments and methods, binary selenium/tellurium compounds, nitrogen-metal/silicon/boron binary compounds, etc., can solve problems such as high cost, complicated process, and long time consumption , to achieve the effect of simple operation, wide range of sources and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The specific embodiment part of the present invention provides a method for preparing a two-dimensional material powder, and the method includes the following steps:

[0070] (1) Ball milling the raw material of the two-dimensional material to obtain a solid material;

[0071] (2) adding an initial dispersion solvent to the solid material obtained in step (1), and performing initial ultrasonic treatment to obtain a dispersion of the two-dimensional material in the initial dispersion solvent;

[0072] (3) Add a precipitating agent to the dispersion of the two-dimensional material in the primary dispersion solvent in step (2), and perform centrifugation and drying after the precipitation is complete to obtain a two-dimensional material powder.

[0073] The specific embodiment part of the present invention also provides a preparation method of the two-dimensional material powder dispersion prepared by the above method, the method is:

[0074] Add the above-mentioned two-d...

Embodiment 1

[0077] This embodiment provides a MoS 2 A method for preparing a two-dimensional material powder, the method comprising the following steps:

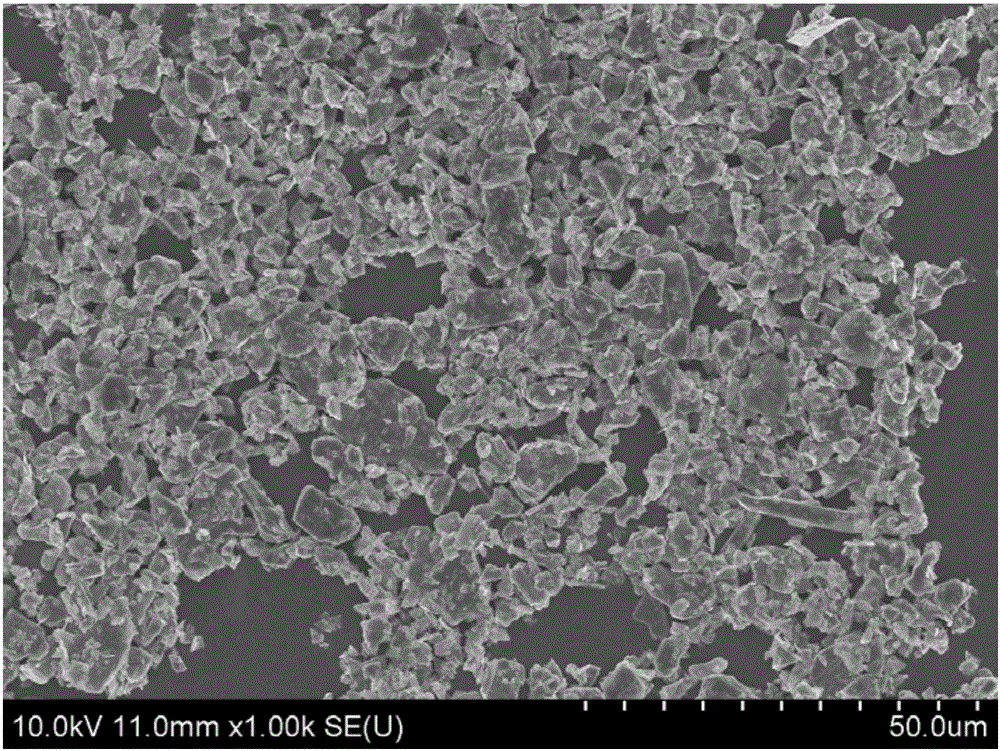

[0078] (1) 1 g of raw material MoS with an average size of 5 μm 2 (The scanning electron microscope such as figure 1 shown), 2g of grinding aid sodium chloride and 10g of agate balls with a diameter of 0.5mm were mixed, ball milled for 0.5h, and then the agate balls were separated, and the obtained samples were washed with water for several times until the sodium chloride was completely washed out, and dried in vacuum , to obtain solid material;

[0079] (2) Add 1L of primary dispersion solvent N-methylpyrrolidone (NMP) to the solid material obtained in step (1), and ultrasonicate with 100W ultrasonic power for 12h to obtain MoS 2 Dispersion in primary dispersion solvent;

[0080] (3) To step (2) MoS 2 Add 1L of precipitant ethyl acetate to the dispersion in the primary dispersion solvent, and after it has fully precipitated, centr...

Embodiment 2

[0085] This embodiment provides a MoS 2 The preparation method of the two-dimensional material powder is the same as that in Example 1.

[0086] This embodiment also provides the above-mentioned MoS 2 The preparation method of two-dimensional material powder ethanol dispersion liquid, described method is as follows:

[0087] 0.1g of the above MoS 2 The two-dimensional material powder was added to 5mL redispersant ethanol, and the power of 200W was ultrasonicated for 5h to obtain MoS 2 Two-dimensional material powder ethanol dispersion, its appearance photo is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com