Compound sludge dehydrating agent as well as preparation method and application thereof

A kind of sludge dehydrating agent and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of not very prominent effect, increase transportation costs, hinder subsequent treatment, etc., achieve the overall consumption of less, good Market prospect, the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

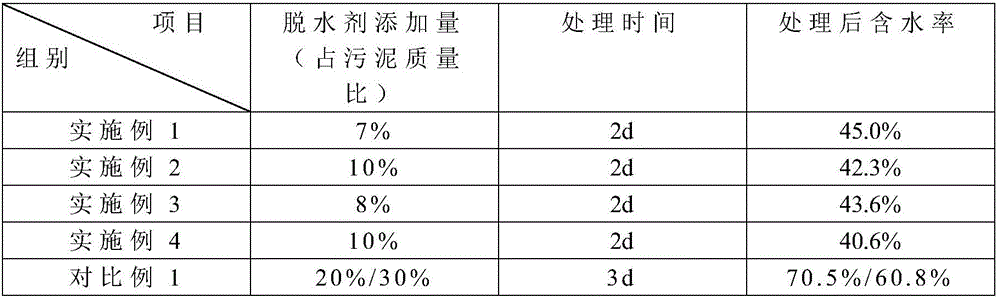

Examples

Embodiment 1

[0026] Mix 2 parts of cationic polyacrylamide, 15 parts of a mixture of bentonite and zeolite, 40 parts of superphosphate, 33 parts of magnesium oxide, 10 parts of fly ash and lime, and dry at 100°C for 30 minutes. The dehydrating agent is sealed and stored for later use.

Embodiment 2

[0028] Mix 3 parts of polydimethyldiallyl ammonium chloride, 10 parts of kaolin, 40 parts of sodium dihydrogen phosphate, 35 parts of calcium oxide, 5 parts of a mixture of fly ash and red mud, and dry at 70°C for 60 minutes. The obtained sludge dewatering agent is sealed and stored for later use.

Embodiment 3

[0030] Mix 5 parts of cationic polyacrylamide, 12 parts of sepiolite, 35 parts of ammonium dihydrogen phosphate, 25 parts of magnesium oxide, and 8 parts of fly ash, dry at 80°C for 50 minutes, and seal the obtained sludge dehydrating agent Save for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com