A kind of aluminum-containing tober mullite autoclaved slag solid brick and its rapid preparation method

A mullite and solid brick technology, which is applied in the field of aluminum-containing tober mullite autoclaved slag solid bricks and its rapid preparation, can solve the problems of low quality, long production cycle, and poor durability of recycled bricks from construction waste. , to achieve good appearance, improve utilization rate and ensure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An aluminum-containing tobmullite autoclaved muck solid brick is prepared by weight percentage of the following components: muck 78.95%, cement 18%, sodium sulfate 3%, and nano titanium dioxide 0.05%. The cement is China Resources PO42.5 cement with a 28d strength of 48MPa. The titanium dioxide is hydrophilic, gold-red type, with a size of 40 nm.

[0036] A solid brick with aluminum-containing toble mullite autoclaved muck and a rapid preparation method thereof, including the following steps:

[0037] (1) Raw material pretreatment: the residual sludge of the muck is dried naturally or sun-dried, and the moisture content is 7.2%;

[0038] (2) Crushing and screening: The slag is crushed by a jaw crusher and passed through a site sieve with an aperture of 10mm. The slag with a particle size of less than 10mm is selected;

[0039] (3) Ingredients: weigh the slag, cement and admixtures according to the dry weight, add a part of water, and stir evenly. The moisture content of the mi...

Embodiment 2

[0049] An autoclaved solid brick with aluminum-containing toble mullite residue is prepared by weight percentage of the following components: 80.95% of residue, 15% of cement, 4% of sodium sulfate, and 0.05% of nanometer zirconium dioxide. The cement is China Resources PO42.5 cement with a 28d strength of 48MPa. The zirconium dioxide is hydrophilic and has a size of 40 nm.

[0050] A solid brick with aluminum-containing toble mullite autoclaved muck and a rapid preparation method thereof, including the following steps:

[0051] (1) Raw material pretreatment: the residual sludge of the muck is naturally dried or sun-dried, and the moisture content is 6.7%;

[0052] (2) Crushing and screening: The slag is crushed by a jaw crusher and passed through a site sieve with an aperture of 10mm. The slag with a particle size of less than 10mm is selected;

[0053] (3) Ingredients: weigh the slag, cement and admixtures according to the dry weight, add a part of water, and stir evenly. The moistu...

Embodiment 3

[0058] The difference between an aluminum-containing tobmullite residue autoclaved solid brick in this embodiment and embodiment 1: It is prepared by weight percentage from the following components: residue 79%, cement 18%, sodium sulfate 3 %. The preparation method and process are the same as in Example 1.

[0059] The performance of the finished product is tested according to GB11945-1999 "Autoclaved Lime-Sand Brick", and all indicators are qualified and reach the MU20 level requirement. The compressive strength is 23.5MPa, the flexural strength is 4.3MPa, the compressive strength after freezing is 21.8MPa, and the mass loss after freezing is 0.4%. The compressive strength and frost resistance can still meet the requirements of MU20 level, but all indexes are worse than the examples. 1.

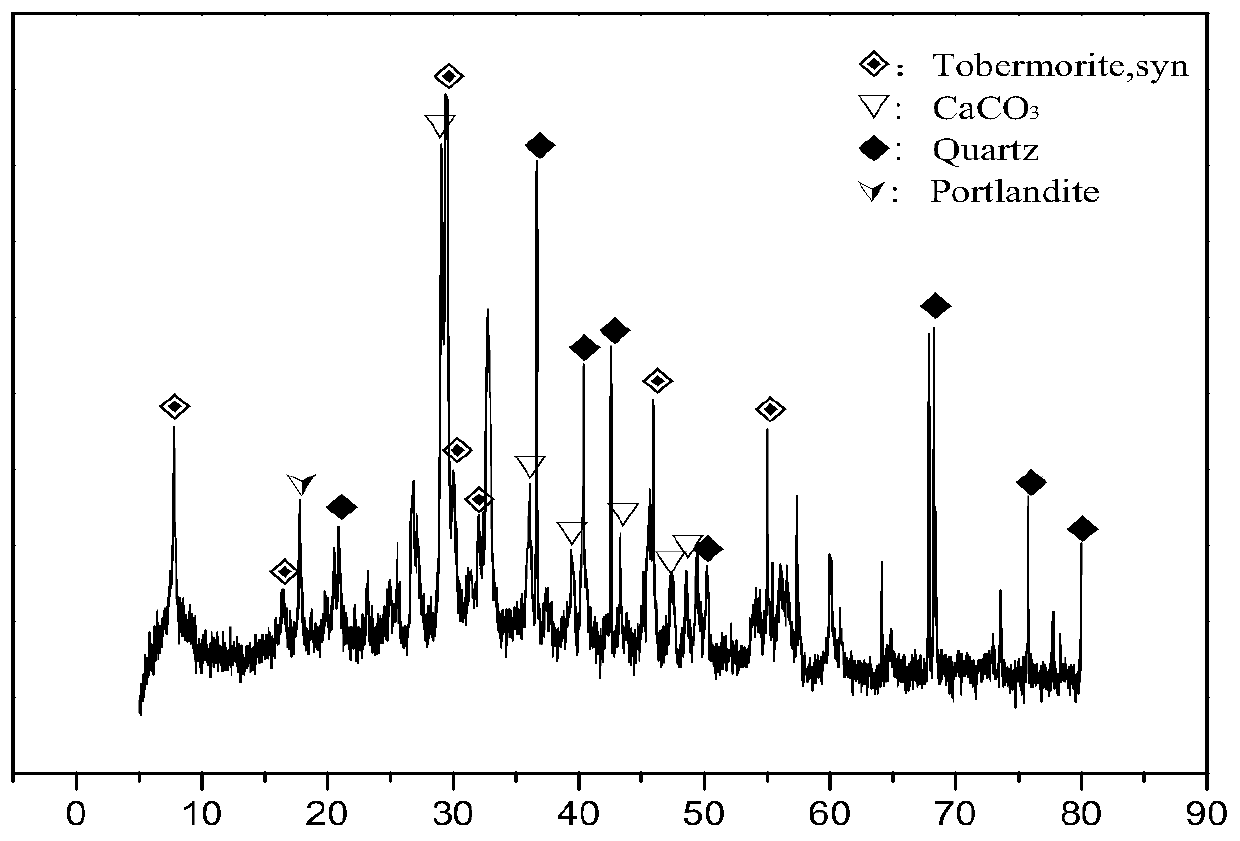

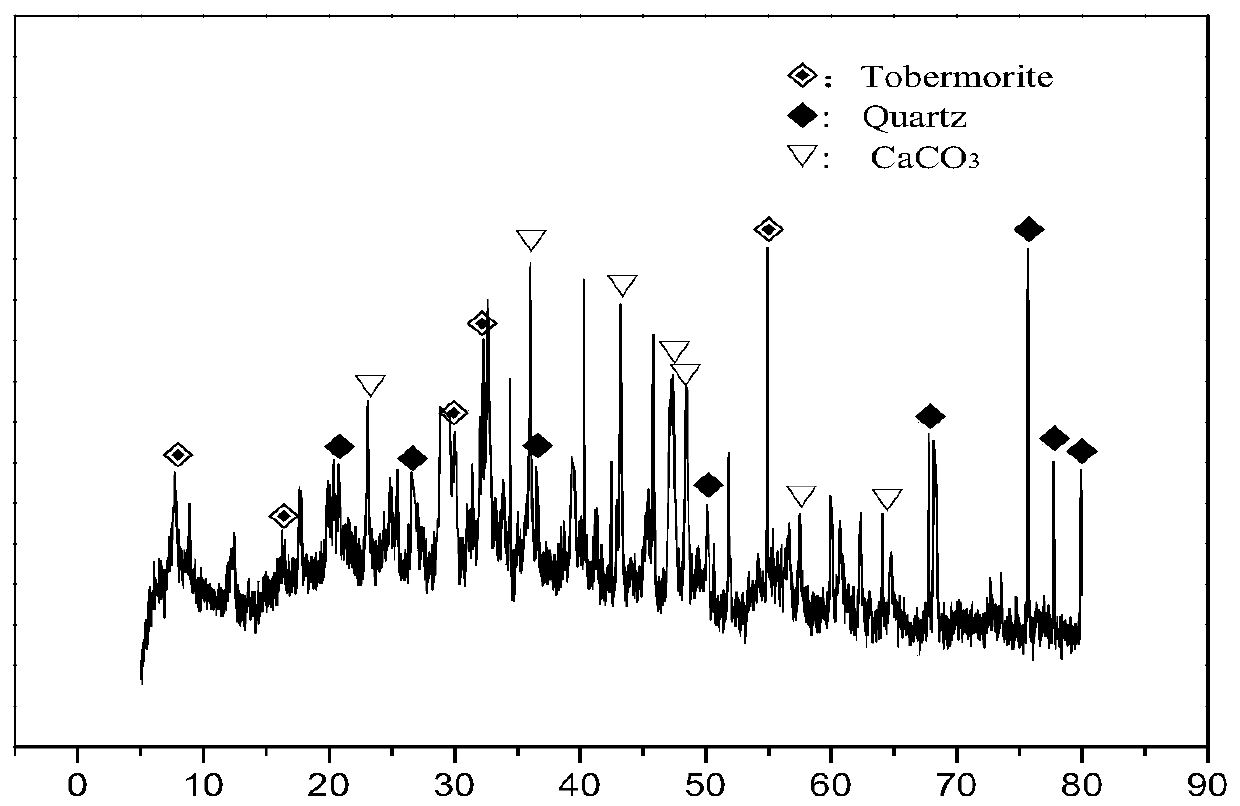

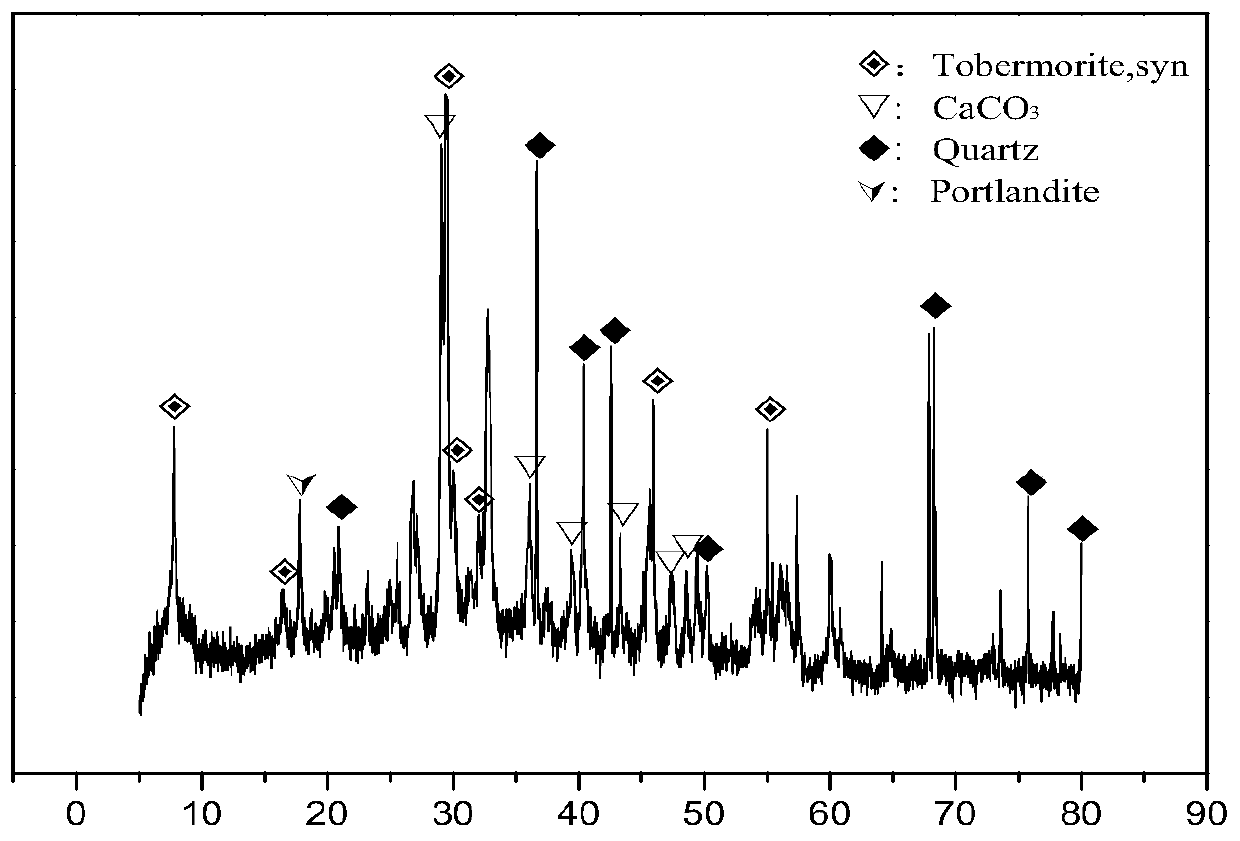

[0060] Crush and grind the muck bricks into powder, pass the 80μm standard sieve for X-ray diffraction analysis, delete the SiO in the XRD spectrum 2 And CaCO 3 The strongest peak and the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com