Method for preparing carbon-based organic fertilizer from biogas slurry

A technology of organic fertilizer and biogas slurry, which is applied in the field of biogas slurry treatment and resource utilization, can solve the problems of lower fertilizer efficiency and fertilization convenience than chemical fertilizers, high production cost, and high transportation cost, so as to achieve emission reduction of odorous substances and avoidance of odorous substances. The effect of additional additions and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

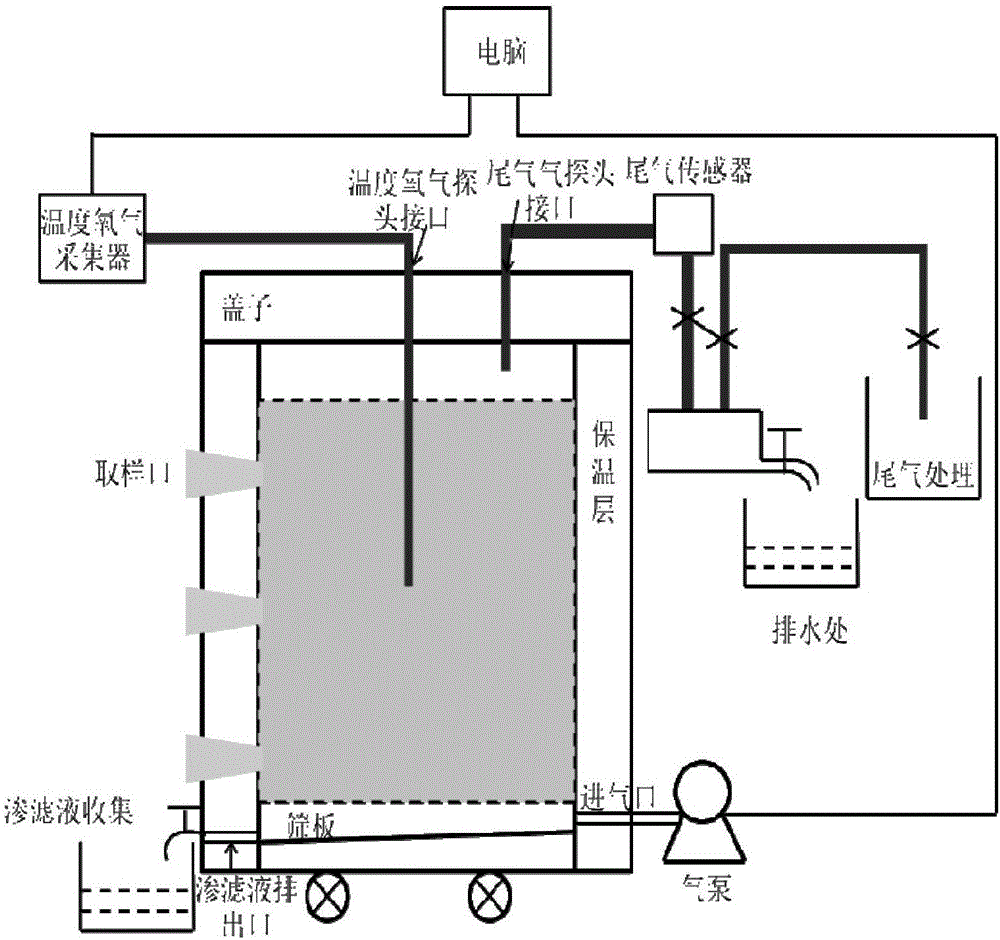

Image

Examples

Embodiment 1

[0045] 1) Crush 20kg of corn stalks to a length of 2cm and 5cm, put 5cm long stalks at the bottom of the cylindrical material bed to a height of 5cm, place 3kg of biochar evenly on the top, mix the remaining stalks with 4.8kg of biochar evenly, and load Into the material bed, the bottom of the material bed is equipped with a filter to facilitate the discharge of biogas slurry. The mass ratio of biochar to total straw was 0.39:1.

[0046] 2) Pass the biogas slurry 0.8m before solid-liquid separation to the top of the material bed through the water pump at a constant speed 3 Finally, all the materials are immersed in the biogas slurry. After the materials are soaked for 3 hours, the biogas slurry in the materials is filtered out through the filter.

[0047] 3) Let the material stand until the water content is 60%, put the material in the material bed into the fermenter, sprinkle 1.2kg of decomposed bacteria agent, stir evenly, and carry out aerobic fermentation. The ventilation...

Embodiment 2

[0051] 1) Crush 20kg of corn stalks to a length of 2cm and 5cm, put 5cm long stalks at the bottom of the cylindrical material bed to a height of 5cm, place 4kg of biochar evenly on the top, mix the remaining stalks with 7.2kg of biochar evenly, and load Into the material bed, the bottom of the material bed is equipped with a filter to facilitate the discharge of biogas slurry. The mass ratio of biochar to total straw was 0.56:1.

[0052] 2) Pass the biogas slurry 1.2m before solid-liquid separation to the top of the material bed through the water pump at a constant speed 3 Finally, all the materials are immersed in the biogas slurry. After the materials are soaked for 3 hours, the biogas slurry in the materials is filtered out through the filter.

[0053] 3) Let the material stand until the water content is 65%, put the material in the material bed into the fermenter, sprinkle 1.4kg of decomposed bacteria agent, stir evenly, and carry out aerobic fermentation. The ventilation...

Embodiment 3

[0057] 1) Crush 20kg of corn stalks to a length of 2cm and 8cm, put 8cm long stalks at the bottom of the cylindrical material bed to a height of 5cm, place 4kg of biochar evenly on the top, mix the remaining straw with 11.3kg of biochar evenly, and load Into the material bed, the bottom of the material bed is equipped with a filter to facilitate the discharge of biogas slurry. The mass ratio of biochar to total straw was 0.77:1.

[0058] 2) Pass the biogas slurry 1.8m before solid-liquid separation to the top of the material bed through the water pump at a uniform speed 3 Finally, all the materials are immersed in the biogas slurry. After the materials are soaked for 3 hours, the biogas slurry in the materials is filtered out through the filter.

[0059] 3) Let the material stand until the water content is 68%, put the material in the material bed into the fermenter, sprinkle 1.5kg of decomposed bacteria agent, stir evenly, and carry out aerobic fermentation. The ventilation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com