Carbon nanotube/phthalocyanine/polyaniline three-element composite material, and preparation method and application thereof

A technology of carbon nanotubes and composite materials, which is applied in the analysis of materials, material analysis by electromagnetic means, instruments, etc., can solve the problem of uniform distribution of difficult polyaniline, achieve high specific surface area, improve gas sensing performance, and high conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

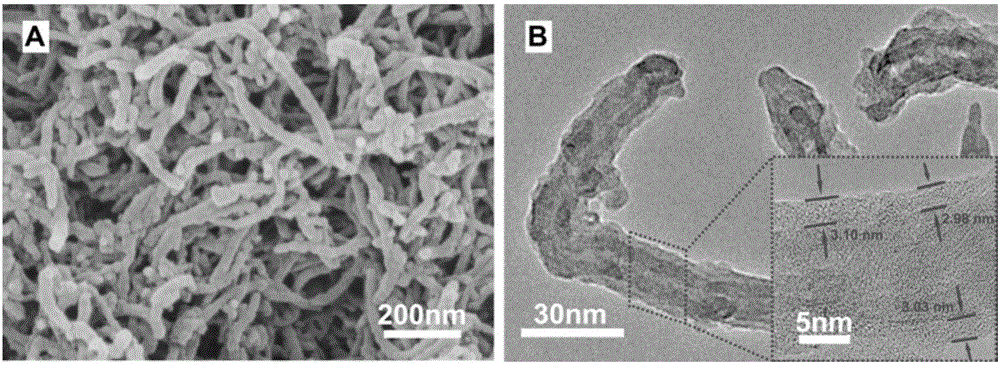

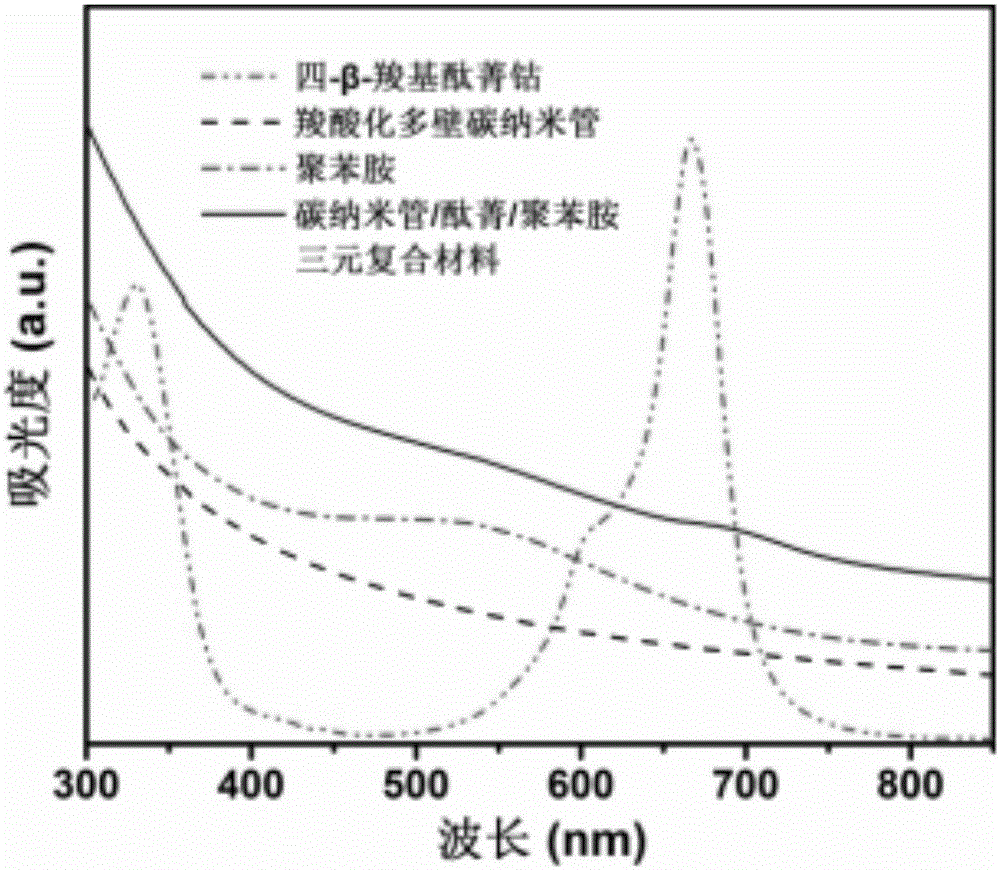

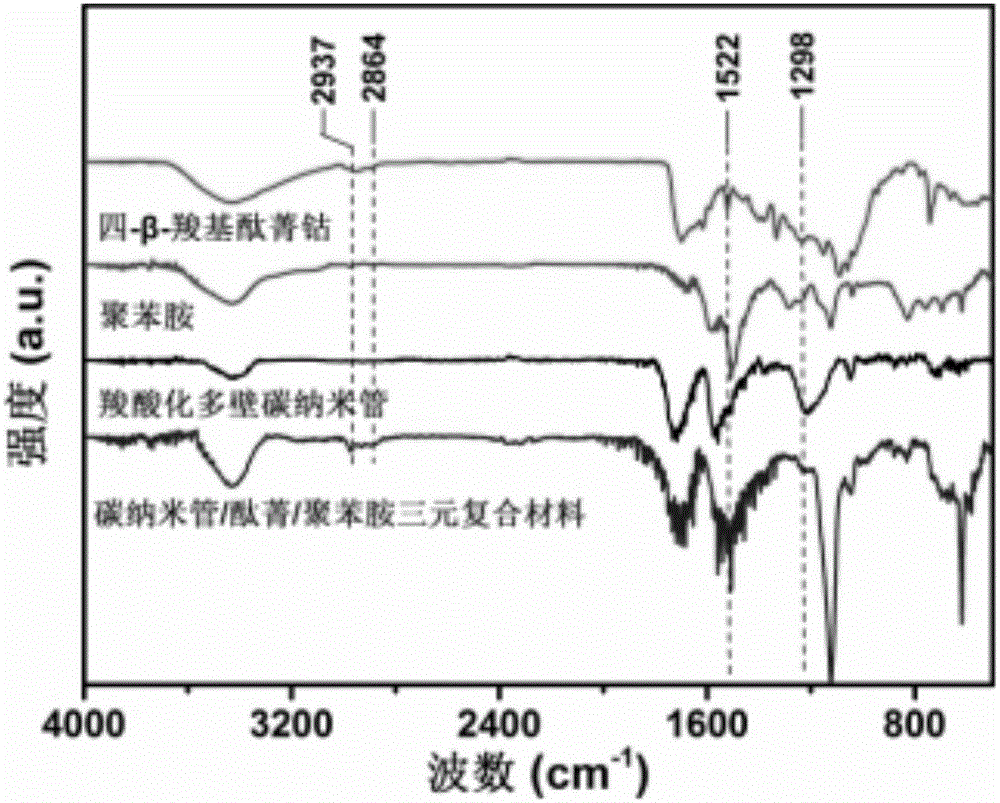

[0026] Embodiment 1: The carbon nanotube / phthalocyanine / polyaniline ternary composite material in this embodiment is composed of 0.40% carboxylated multi-walled carbon nanotubes and 2.48% tetra-β-carboxyphthalocyanine cobalt , 1.20% aniline, 4.97% ammonium persulfate, 48.04% N,N-dimethylformamide (DMF) and 42.91% distilled water; the specific preparation method is achieved through the following steps:

[0027] Step 1, divide the distilled water into two equal parts, and add ammonium persulfate to one of the distilled waters to prepare ammonium persulfate solution;

[0028] Step 2. Add tetra-β-carboxymetallophthalocyanine cobalt and carboxylated multi-walled carbon nanotubes to N,N-dimethylformamide (DMF) sequentially, ultrasonically vibrate for 2h at an ultrasonic frequency of 40kHz, and centrifuge Separate, wash with distilled water, dry at 80°C, then add aniline and another portion of distilled water weighed in step 1, vibrate ultrasonically for 30min at an ultrasonic freque...

specific Embodiment approach 2

[0047] Specific embodiment two: the carbon nanotube / phthalocyanine / polyaniline ternary composite material in this embodiment is made of 0.60% carboxylated multi-walled carbon nanotube, 1.47% tetra-beta-carboxy manganese phthalocyanine , 0.60% aniline, 3.95% ammonium persulfate, 46.92% N,N-dimethylformamide (DMF) and 46.46% distilled water; the specific preparation method is achieved through the following steps:

[0048] Step 1, divide the distilled water into two equal parts, and add ammonium persulfate to one of the distilled waters to prepare ammonium persulfate solution;

[0049] Step 2. Add tetra-β-carboxymetallomanganese phthalocyanine and carboxylated multi-walled carbon nanotubes to N,N-dimethylformamide (DMF) in turn, ultrasonically vibrate for 3h at an ultrasonic frequency of 40kHz, and centrifuge Separate, wash with distilled water, dry at 80°C, then add aniline and another portion of distilled water weighed in step 1, vibrate ultrasonically for 40min at an ultrasoni...

specific Embodiment approach 3

[0056] Specific Embodiment Three: The carbon nanotube / phthalocyanine / polyaniline ternary composite material in this embodiment is composed of 0.50% carboxylated multi-walled carbon nanotubes and 2.09% tetra-beta-carboxyphthalocyanine nickel , 1.00% aniline, 4.02% ammonium persulfate, 47.12% N,N-dimethylformamide (DMF) and 45.27% distilled water; the specific preparation method is achieved through the following steps:

[0057] Step 1, divide the distilled water into two equal parts, and add ammonium persulfate to one of the distilled waters to prepare ammonium persulfate solution;

[0058] Step 2, adding tetra-β-carboxymetallic nickel phthalocyanine and carboxylated multi-walled carbon nanotubes to N,N-dimethylformamide (DMF) in turn, ultrasonically vibrating for 2.5h at an ultrasonic frequency of 40kHz, Centrifuge, wash with distilled water, dry at 80°C, then add aniline and another portion of distilled water weighed in step 1, vibrate ultrasonically for 35 minutes at an ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com