A kind of polyaryletherketone foam material containing phthalein side group and preparation method thereof

A technology of polyaryletherketone and foam materials, which is applied in the field of polyaryletherketone foam materials containing phthalein side groups and its preparation, can solve the problems of low foaming ratio and uneven cell size, and achieve high foaming ratio, Uniform cells and wide foaming window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention firstly provides a kind of preparation method of polyaryletherketone foam material containing phthalein side group, and this method comprises:

[0040] Step 1: Molding polyaryletherketone containing phthalein side groups on a sulfur press to obtain a cross-linked polyaryletherketone sample containing phthalein side groups;

[0041] Step 2: In the autoclave, place the cross-linked polyaryletherketone sample containing phthalein side groups obtained in step 1 in supercritical CO 2 In the process, the swelling and infiltration are carried out at the saturation temperature of 200-350°C and the saturation pressure of 8-30MPa, the saturation time is 0.5-3h, the pressure is released quickly, and then the foam is taken out from the autoclave and cooled to room temperature to obtain phthalein-containing Side group polyaryletherketone foam material;

[0042] The polyaryletherketone containing phthalein side groups is in an amorphous state.

[0043] According...

Embodiment 1

[0061] Add phenolphthalein (70.7mmol), difluorobenzophenone (70mmol), K 2 CO 3 (80.5mmol), TMS (65.5ml), toluene (35ml), under the condition of nitrogen protection, heat the above mixture to 140°C to azeotropically remove water, keep the temperature for 2h, remove toluene, continue to heat to 220°C for 2.5h, cool down, Add 250ml DMAc to dilute, precipitate in ethanol / water, filter, pulverize the precipitate, and repeatedly boil and wash with deionized water 5 times to remove inorganic salts and residual solvents, and dry to obtain polyaryletherketone (PEK-C ).

[0062] The dried PEK-C sample (Mw=13.5×10 4 , PDI=2.8) Molding in a sulfur press, temperature 360 ° C, pressure 5 MPa, stop heating after 30 minutes, after the temperature drops below 100 ° C, release the pressure and take out the sample, thickness 4mm.

[0063] Place the prepared PEK-C sample in an autoclave, seal the autoclave, and use high-pressure CO 2 Purge the autoclave 2-3 times, the purpose is to remove t...

Embodiment 2

[0070] The dried PEK-C sample (Mw=13.5×10 4 , PDI=2.8) Molding in a sulfur press, temperature 360 ° C, pressure 5 MPa, stop heating after 30 minutes, after the temperature drops to 100 ° C, release the pressure and take out the sample, thickness 4 mm.

[0071] Place the dried PEK-C sample in the autoclave, seal the body of the autoclave, and use high-pressure CO 2 Purge the autoclave 2-3 times, the purpose is to remove the air in the cavity, and then inject CO into the autoclave through the pressurization system 2 Gas, control the constant pressure to 10MPa, increase the temperature of the kettle to 290°C, keep the pressure for 2.5h, then quickly reduce the pressure to normal pressure through the pressure reducing valve, the pressure reduction rate is >10MPa, and open the kettle to take out the sample and cool it to room temperature , so as to obtain PEK-C foam samples.

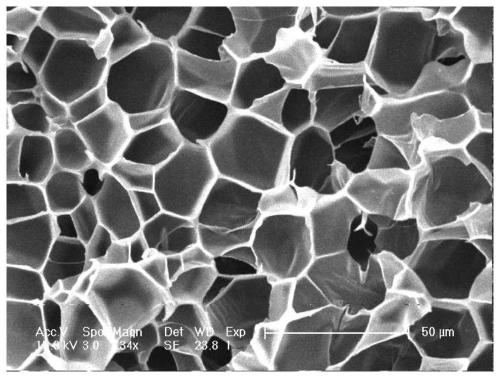

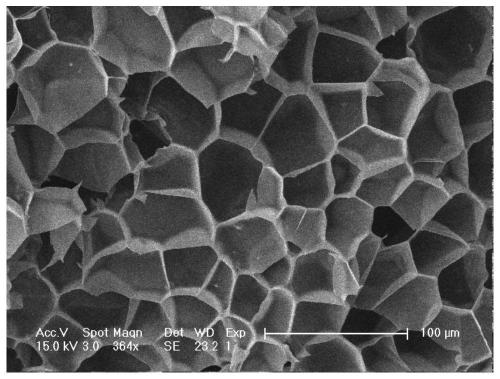

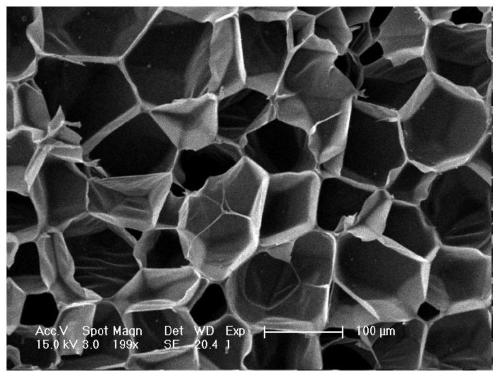

[0072] The sample obtained in Example 2 is quenched with liquid nitrogen, and the section is subjected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com