Preparation method of phosphate esterification starch adhesive based formaldehyde-free building inner wall putty

A technology of esterifying starch and starch, which is applied in the direction of starch-derived adhesives, adhesive types, filling pastes, etc., can solve the problems of high viscosity of starch adhesives and poor bonding strength that have not been reported on building interior wall putty. There are still some problems to be improved to achieve the effect of improved construction performance, good fluidity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing phosphated starch adhesive-based formaldehyde-free building interior wall putty, comprising the following steps:

[0044] a. Preparation of phosphated starch adhesive:

[0045] The first step: batching: be 1.3% sodium dihydrogen phosphate by mass percentage and raw material component, 10% starch, 10% mass percentage concentration is the NaOH aqueous solution of 20%, and 78.7% water (included in preparation process The proportioning of 8% in the second step and 70.7% in the fourth step) gets raw material sodium monohydrogen phosphate or / and sodium dihydrogen phosphate, starch, the NaOH aqueous solution that mass percent concentration is 20%, and water; 4 parts of washing water, each with a quality of 25% of the starch quality, set aside;

[0046] Preparation process:

[0047] The second step: esterification synthesis: add 8% water to sodium dihydrogen phosphate, stir to dissolve, adjust the pH value to 5.5 with NaOH aqueous solution with a mass p...

Embodiment 2~7

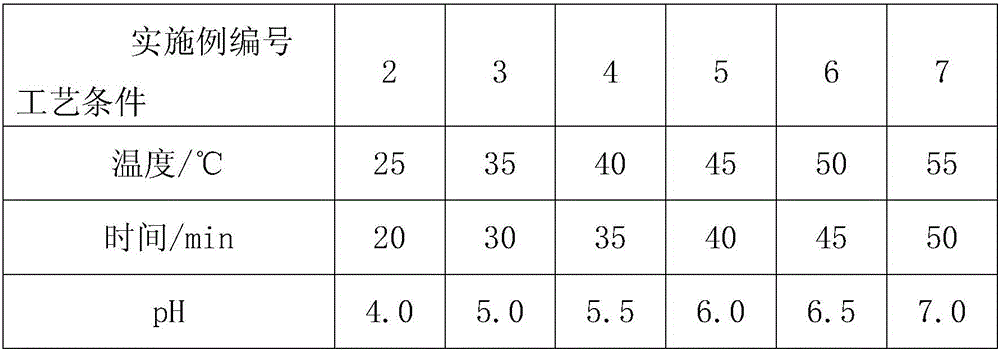

[0061] A preparation method of phosphated starch adhesive-based formaldehyde-free building interior wall putty, mainly aiming at changing the temperature, time, pH and other process conditions of esterification of phosphated starch adhesive, and the content of each raw material component Consistent with the preparation procedure and embodiment 1;

[0062] Table 1: The different technological conditions of esterification synthesis among the embodiment 2~7 are shown in the table below:

[0063]

[0064] The components, preparation process and construction process of the phosphated starch adhesive-based formaldehyde-free building interior wall putty in Examples 2 to 7 are the same as those in Example 1, and are omitted;

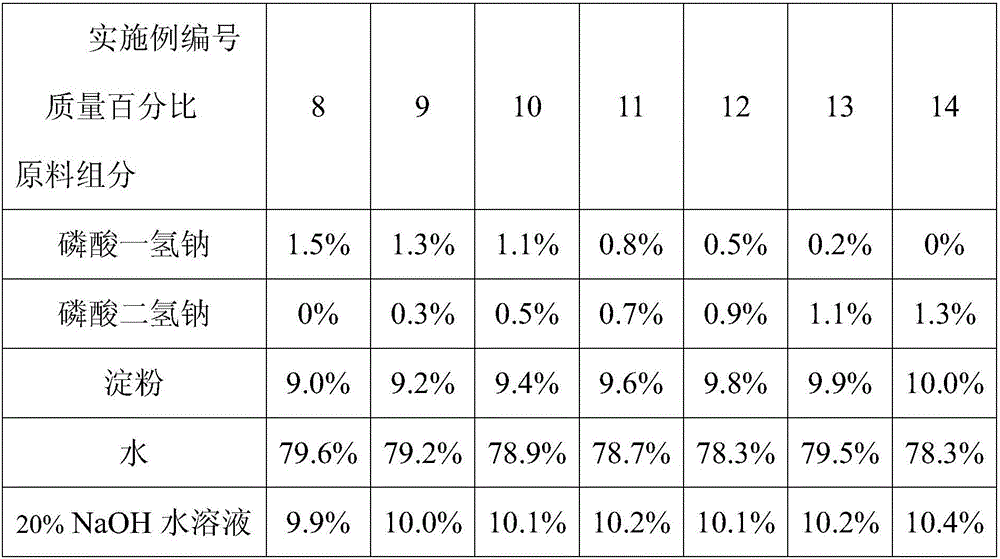

Embodiment 8~14

[0066] A method for preparing phosphated starch adhesive-based formaldehyde-free building interior wall putty, comprising the following steps:

[0067] a. Preparation of phosphated starch adhesive:

[0068] The specific mass percentages of each raw material component in the phosphated starch adhesive of each embodiment are shown in Table 2;

[0069] Configuration process: its preparation process is consistent with embodiment 1;

[0070] Table 2: The specific mass percentages of the components of the phosphated starch adhesive in each embodiment are shown in the following table:

[0071]

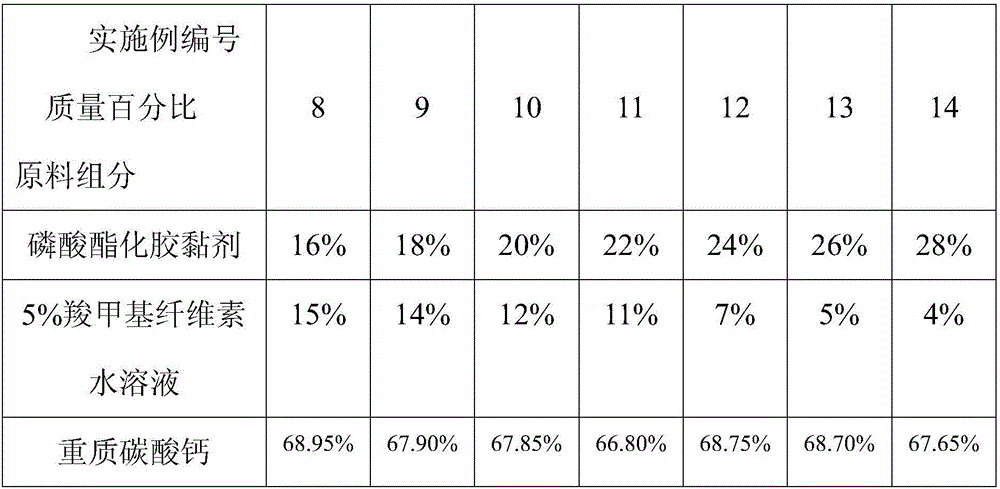

[0072] b. Preparation of phosphated starch adhesive-based formaldehyde-free building interior wall putty:

[0073] The specific mass percentage consumption of each raw material component of A component is shown in the following table 3 in each embodiment;

[0074] Configuration process: its preparation process is consistent with embodiment 1;

[0075] Table 3: The specific mass percent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com