Multi-coating composite material taking magnesium/magnesium alloy as matrix and preparation method of multi-coating composite material

A composite material and magnesium alloy technology, applied in the field of multi-coated composite materials and its preparation, can solve the hazards of human bone and tissue growth, the deterioration of mechanical properties tensile strength, compressive yield strength and fatigue strength, and the improvement of corrosion resistance Porosity and other issues with small range, to achieve good advantages and controllability, superior corrosion resistance, and enhanced corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

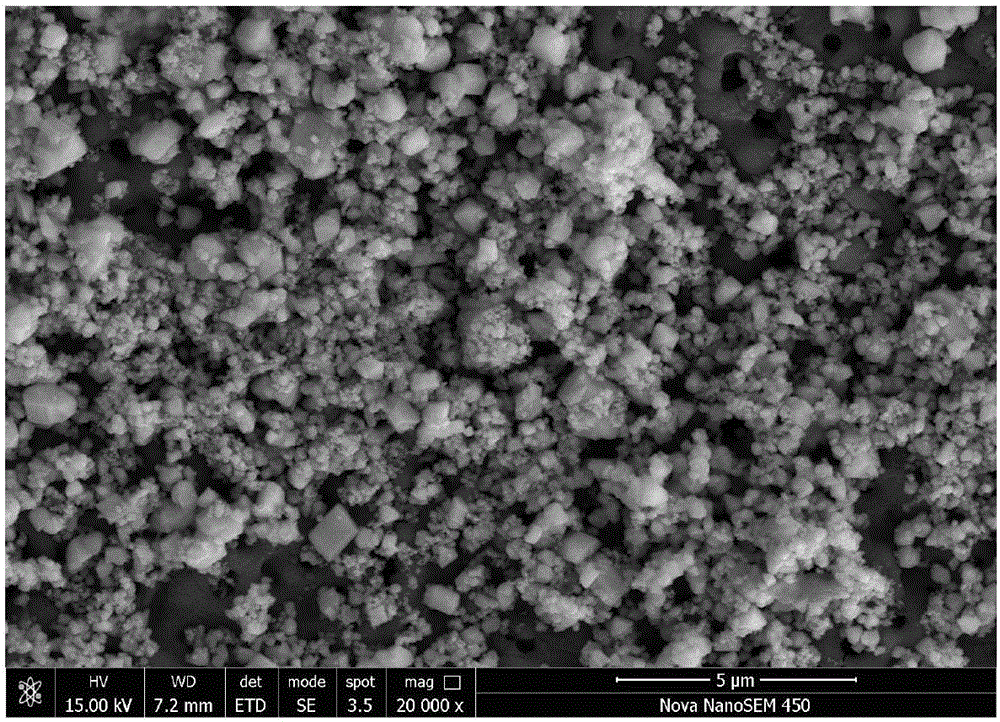

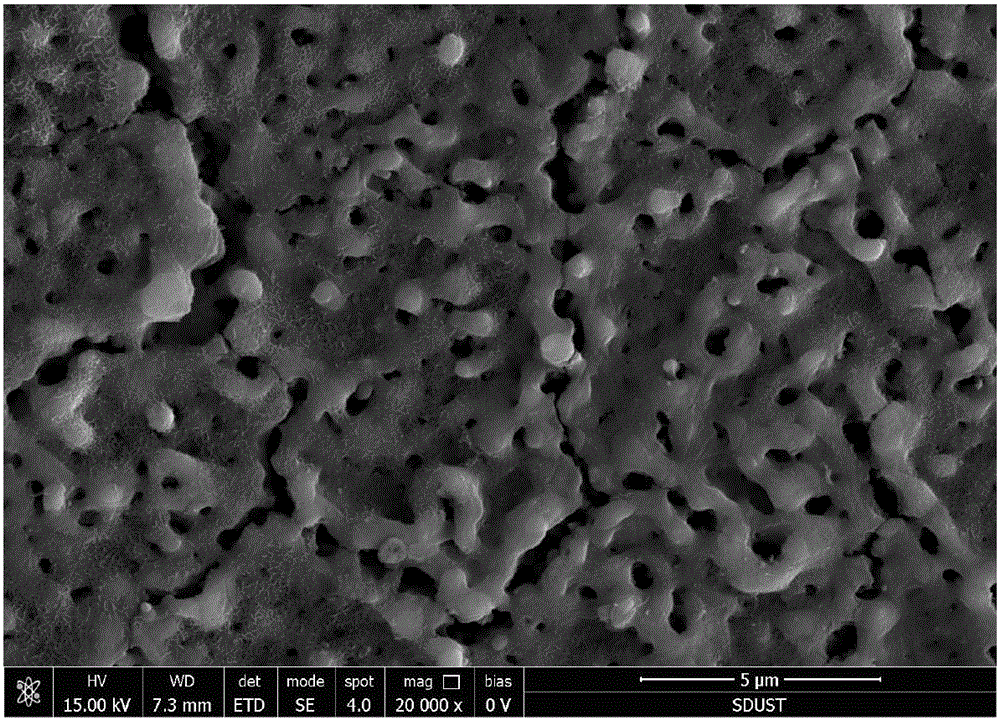

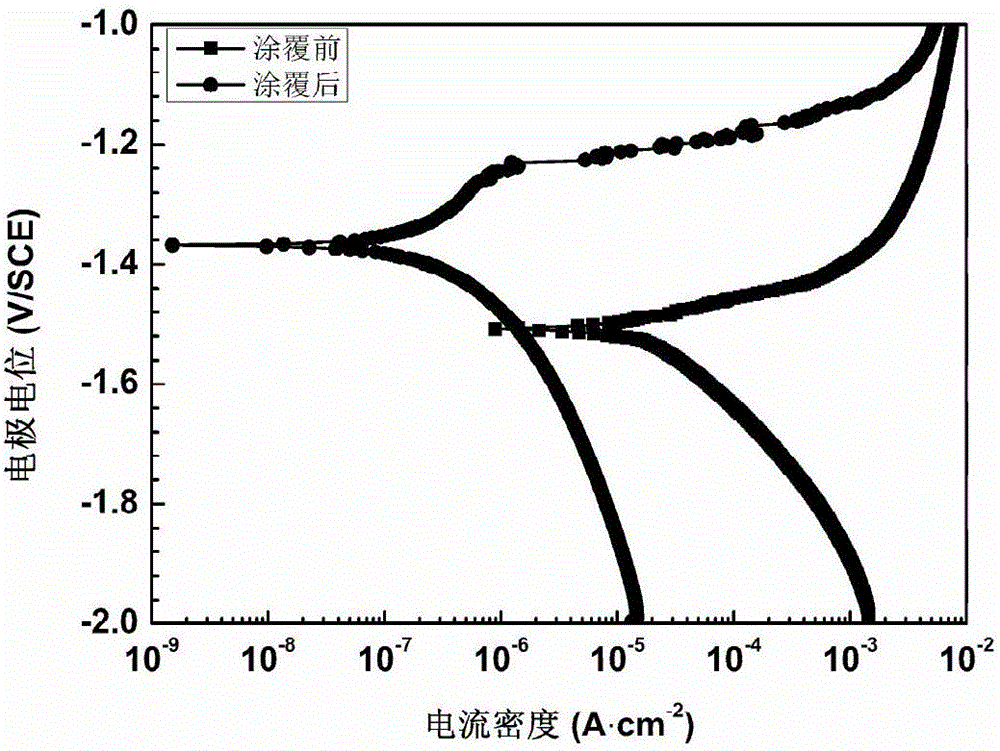

Embodiment 1

[0039] A multi-coated composite material based on magnesium alloy AZ31. The multi-coated composite material has a layered structure, and from the inside to the outside is a magnesium / magnesium alloy substrate, a micro-arc oxidation film coating, and a strong positive charge precursor. Body coating and mixed coating, the mixed coating includes five layers, each layer is stacked in turn, the next layer is coated on the previous layer, and each layer is modified two layers. A composite structure of a tin oxide coating and a negatively charged polyelectrolyte coating, wherein the modified tin dioxide coating is coated on the corresponding negatively charged polyelectrolyte coating. The modified tin dioxide coating is a crystalline coating. The total thickness of the mixed coating is 3-5 μm.

[0040] A self-assembly method to prepare nano-SnO based on magnesium alloy AZ31 2 The preparation method of the multi-coat composite material, comprises the steps:

[0041] Step 1, grindin...

Embodiment 2

[0056] The base material of this embodiment is magnesium alloy AZ91D, and the rest are the same as those of Embodiment 1.

Embodiment 3

[0058] The base material of this embodiment is magnesium, and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com