Abrasion-resistant slurry pump

A slurry pump and pump body technology, which is applied in the field of rotary power pump equipment, can solve problems such as difficulty in meeting use requirements, many types and specifications of ceramic sheets, pump body rupture, etc., to achieve good anti-abrasion effect, process and cost advantages, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

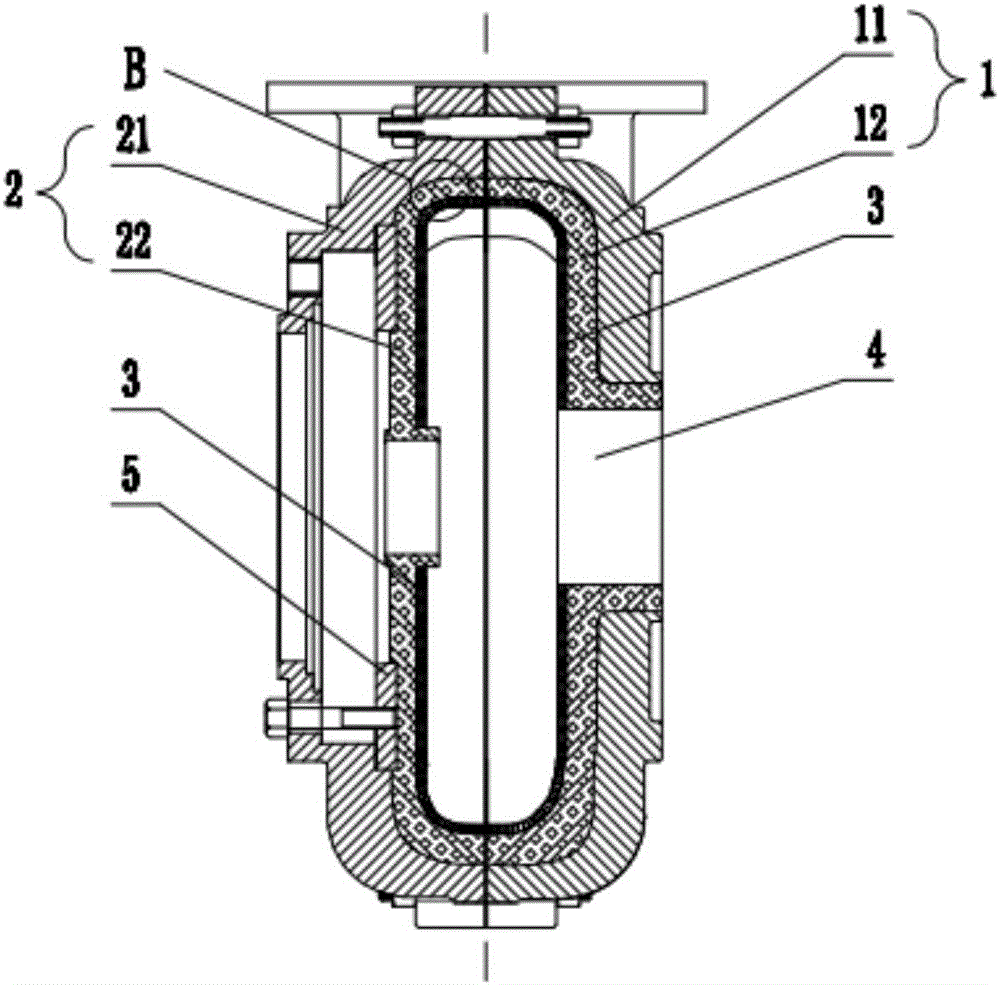

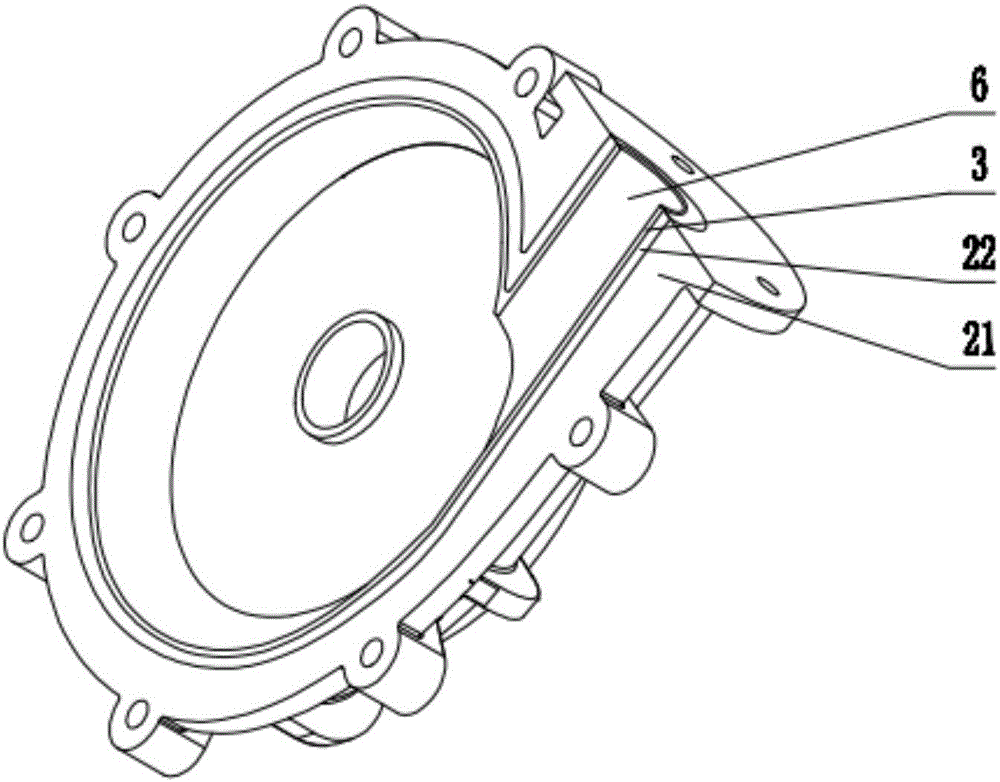

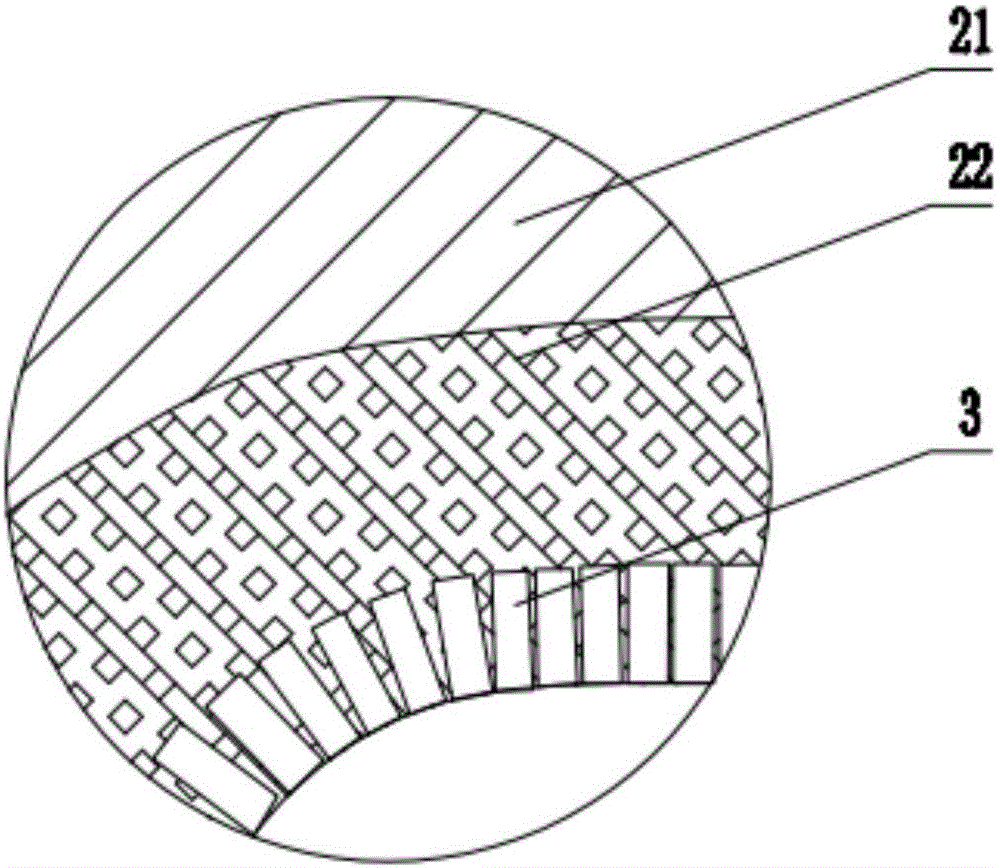

[0035] Specific embodiments of the present invention 1 refer to Figure 1-5As shown, a wear-resistant slurry pump body of the present invention includes a front pump body 1 provided with a suction port 4, a rear pump body 2, and a discharge port 6. The front pump body 1 and the rear pump body 2 are at least three layers The material is composed of a metal shell, a composite wear-resistant material, and a ceramic sheet 3 embedded in the composite wear-resistant material. Among them, the metal shell layer can improve the mechanical strength of the pump body to meet the strength requirements of the pump body. There are two functions of the composite wear-resistant material: one is to fill the gap between the ceramic sheets 3, and use the binder in the composite wear-resistant material to fix the ceramic sheet 3; the other is to use the composite wear-resistant material to resist the fine particles of the medium Scouring wear. Moreover, the ceramic sheet has excellent wear resis...

Embodiment 2

[0041] Specific embodiment 2 of the present invention refers to Image 6 As shown, the main structure of Embodiment 2 of the present invention is the same as that of Embodiment 1. The difference is that in this embodiment, an anti-extrusion wear-resistant plate 9 is provided on the flow surface of the pump body located in the axial projection area of the impeller. , the anti-extrusion plate wear-resistant plate 9 has a larger area, so its bonding surface with the adhesive is also larger, and its fixing reliability is still high. The anti-extrusion wear-resistant plate 9 on the front pump body 1 is a zirconia ceramic annular plate with an outer diameter of 300 mm and an inner diameter of 150 mm and a thickness of 12 mm; while the anti-extrusion wear-resistant plate 9 on the rear pump body 2 is 8 pieces with an outer diameter 300mm silicon nitride ceramic fan-shaped plate with an inner diameter of 120mm, an angle of 45 degrees, and a thickness of 12mm. The setting of the anti...

Embodiment 3

[0044] Figure 7 The implementation 3 of the present invention shown is roughly the same as the embodiment 2, the difference is that the anti-extrusion wear-resistant plate 9 is arranged on the anti-extrusion metal skeleton 10, and the anti-extrusion wear-resistant plate 9 is hard alloy with a thickness of 3mm , the material is YG6 tungsten-cobalt alloy, the anti-extrusion metal frame 10 is a carbon steel plate with a thickness of 12mm, and the anti-extrusion wear-resistant plate 9 can be fixed on the anti-extrusion metal frame 10 by copper brazing, or it can be fixed on the anti-extrusion metal frame 10 with an adhesive 10 on the anti-extrusion metal skeleton. By setting the anti-extrusion metal skeleton 10, on the one hand, the ability of the pump body to resist extrusion damage caused by particles with a hardness of about 10 mm can be improved, and on the other hand, the thickness of the expensive anti-extrusion wear-resistant plate 9 can be reduced , thereby reducing manu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com