Method for enhancing electroluminescence of zinc oxide-gallium nitride heterostructure

A heterogeneous structure, zinc oxide technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as the influence of crystal structure and energy band structure on luminous efficiency, improve electroluminescent performance, increase internal quantum efficiency, and solve The effect of low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

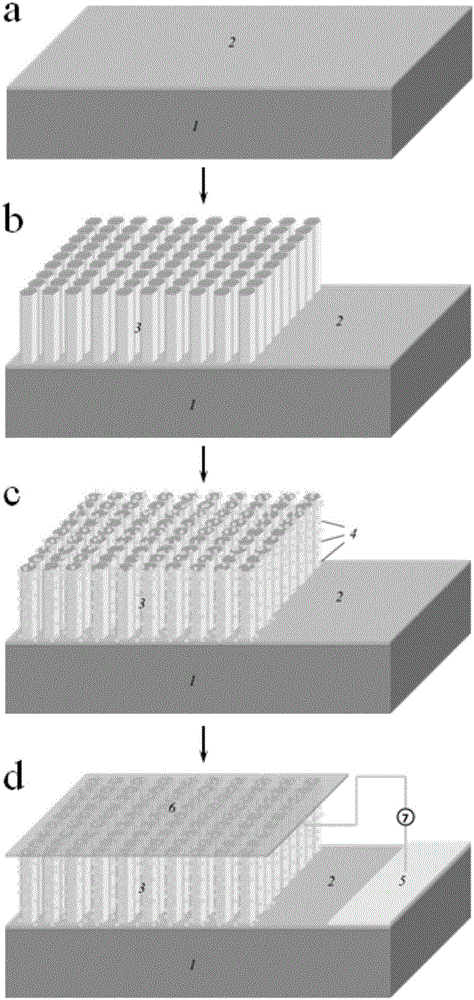

[0029] 1. Select ZnO powder and graphite powder with a purity of 98.00% and mix and grind them for 20 minutes at a mass ratio of 1:1, then place 0.5 g of the ground mixture into an opening at one end, and seal it with a quartz tube with a diameter and length of 3 cm and 30 cm, respectively. end;

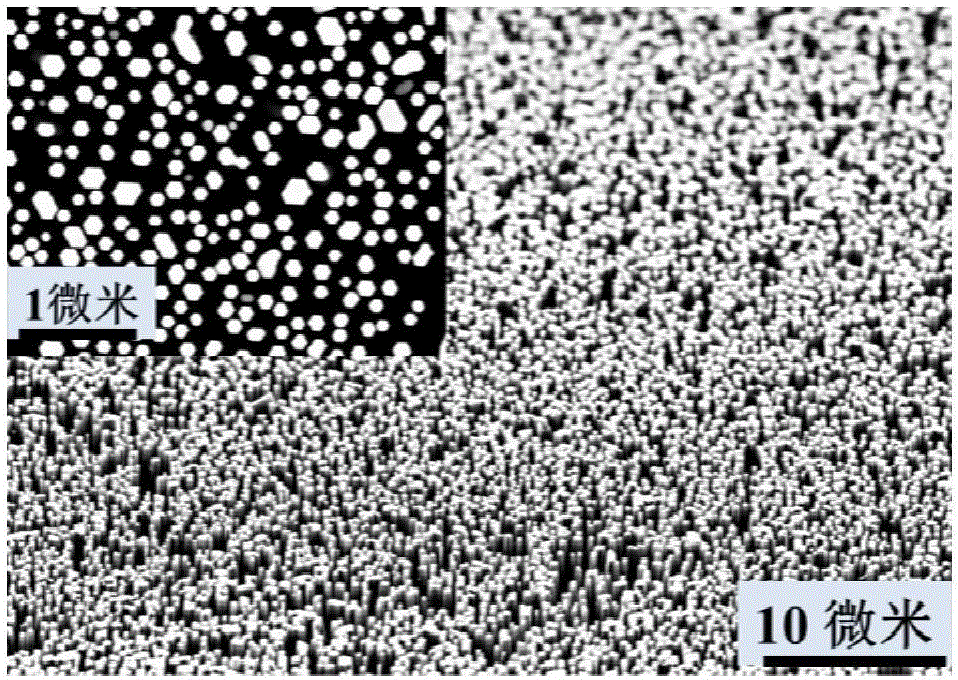

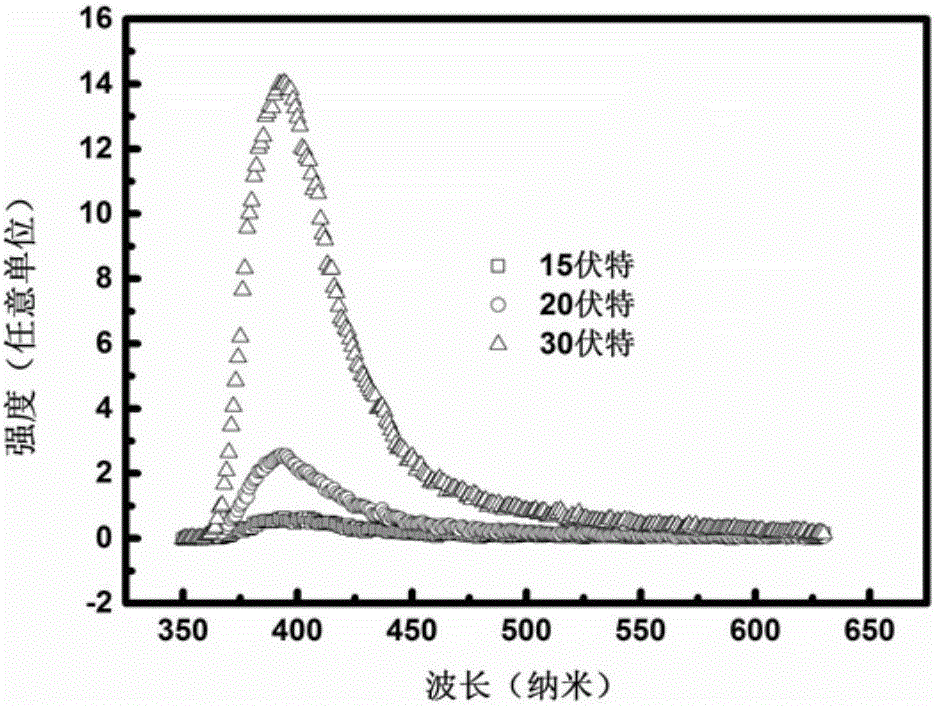

[0030] 2. Clean the 0.5cm*1.0cm p-GaN substrate 2 (0001) with acetone, absolute ethanol and deionized water at an ultrasonic frequency of 30KHz for 15min, then dry it with nitrogen, and place it at the open end of the quartz tube , about 3cm away from the nozzle, then place the quartz tube with the powder source and the substrate in a horizontal quartz tube furnace at a temperature of 1050°C; close the tube furnace, turn on the mechanical pump, evacuate to 266Pa, and ventilate with argon and oxygen, the flow rates were 150sccm and 15sccm, respectively, and reacted for 20 minutes; turn off the mechanical pump, ventilate the air to normal pressure, open the tube furnace, take out the s...

Embodiment 2

[0035] 1. Select ZnO powder and graphite powder with a purity of 98.50% and mix and grind them for 20 minutes at a mass ratio of 1:1, then place 0.5 g of the ground mixture into an opening at one end, and seal it with a quartz tube with a diameter and length of 3 cm and 30 cm, respectively. end;

[0036]2. Clean the 0.5cm*1.0cm p‐GaN substrate 2 (0001) with acetone, absolute ethanol and deionized water at an ultrasonic frequency of 60KHz for 10 minutes, and then dry it with nitrogen and place it on a quartz The open end of the tube is about 3 cm away from the tube mouth, and then the quartz tube equipped with the powder source and the substrate is placed in a horizontal quartz tube furnace at a temperature of 950 °C; the tube furnace is closed, the mechanical pump is turned on, and the vacuum is evacuated to 266Pa. Flow argon and oxygen at a flow rate of 130 sccm and 13 sccm respectively, and react for 23 minutes; turn off the mechanical pump, ventilate the air to normal press...

Embodiment 3

[0040] 1. Select ZnO powder and graphite powder with a purity of 99.00% and mix and grind them for 20 minutes at a mass ratio of 1:1, then place 0.5 g of the ground mixture into an opening at one end, and seal it with a quartz tube with a diameter and length of 3 cm and 30 cm, respectively. end;

[0041] 2. Clean the 0.5cm*1.0cm p-GaN substrate 2 (0001) with acetone, absolute ethanol and deionized water at an ultrasonic frequency of 50KHz for 13min, then dry it with nitrogen, and place it at the open end of the quartz tube , about 3cm away from the nozzle, then place the quartz tube with the powder source and the substrate in a horizontal quartz tube furnace at a temperature of 1000°C; close the tube furnace, turn on the mechanical pump, evacuate to 266Pa, and ventilate with argon and oxygen at flow rates of 180 sccm and 18 sccm respectively, and react for 15 minutes; turn off the mechanical pump, ventilate the air to normal pressure, open the tube furnace, take out the sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com