Preparation method for highly acid Y type molecular sieve

A technology of molecular sieve and acid solution, which is applied in the direction of crystalline aluminosilicate zeolite and octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of micropore channel damage and molecular sieve lattice collapse, etc., so as to avoid the destruction of micropore channels, Low cost, less diffusion limiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

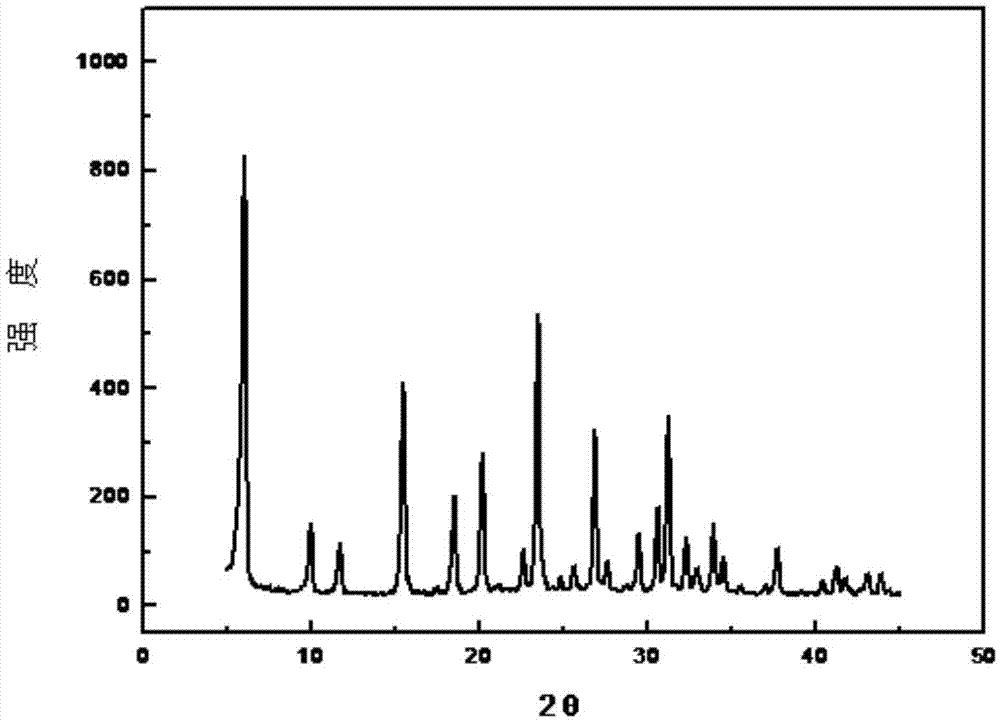

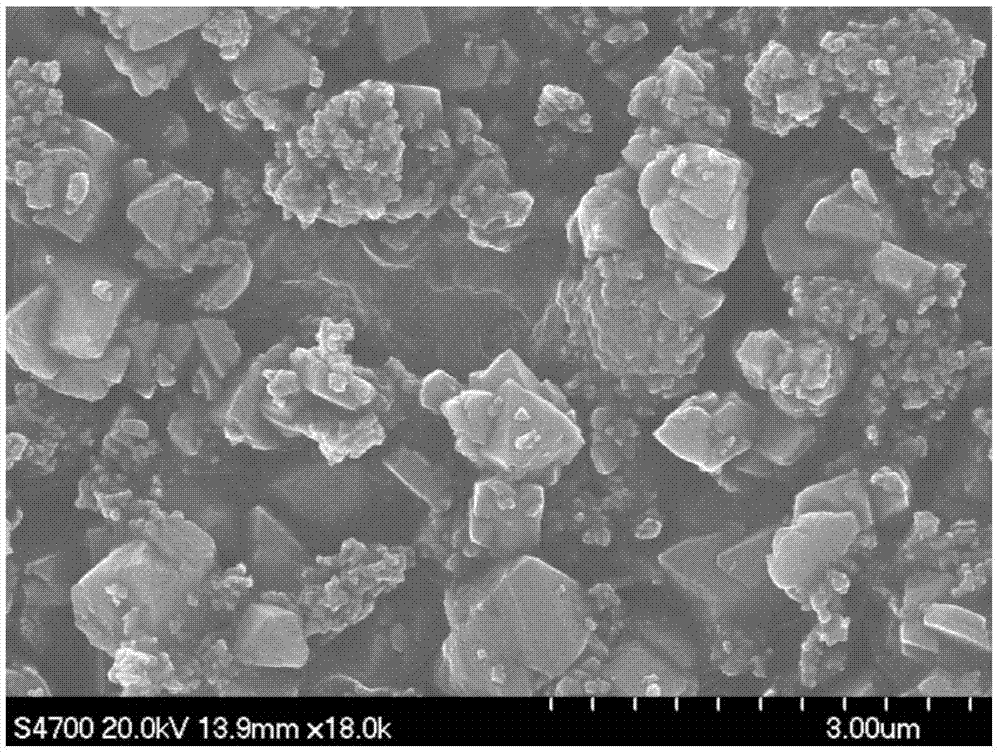

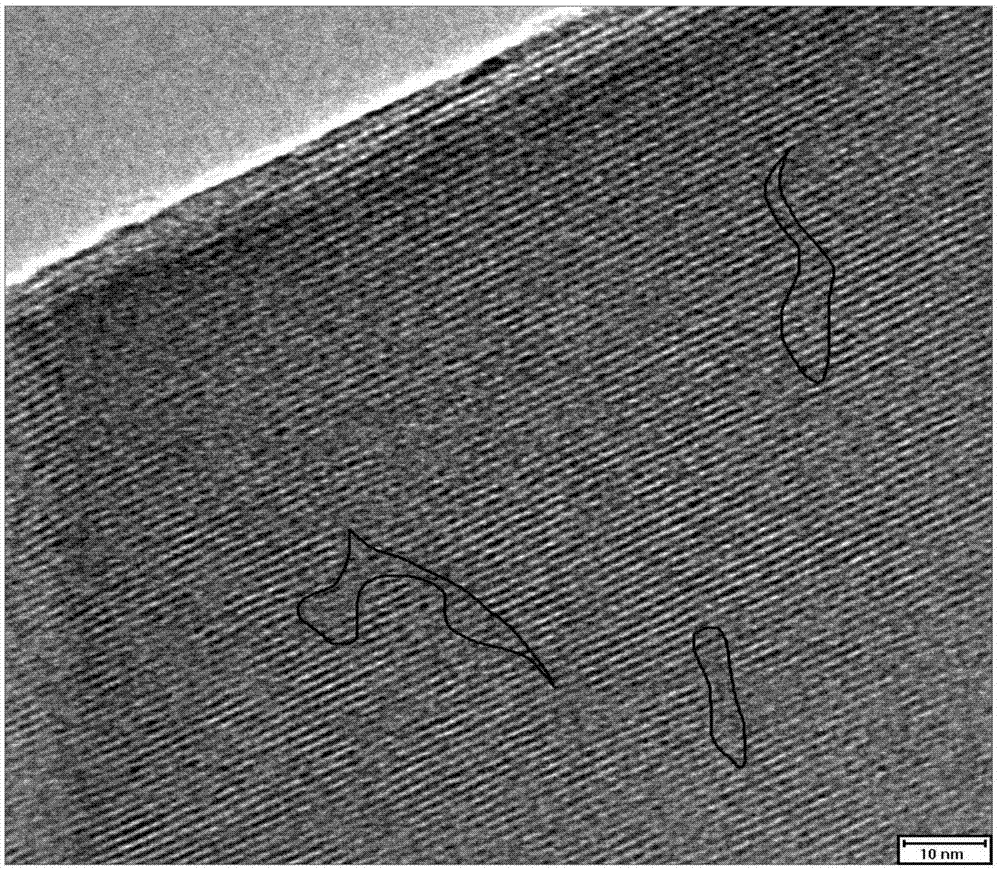

[0049] The present embodiment provides a kind of preparation method of Y-type molecular sieve, and it comprises the following steps:

[0050] (1) Weigh 30.3g of water glass, 7.09g of sodium hydroxide, 2.25g of sodium metaaluminate and mix with 44mL of deionized water, stir rapidly for 1 hour, and then stand in a water bath at 30°C for 3 hours to obtain a Y-type molecular sieve directing agent.

[0051] (2) Weigh water glass, 13g Y-type molecular sieve directing agent and deionized water and mix evenly, stir for 2 hours; dissolve low partial solution (sodium hydroxide and sodium aluminate in deionized water) and aluminum sulfate solution (aluminum sulfate octadecahydrate dissolved in deionized water) into the reaction system to obtain aluminosilicate gel (SiO 2 :Al 2 o 3 : Na 2 O: H 2 O=10:1.2:10:150), stir until the system is uniform, then crystallize at 90°C for 18h; the obtained product is cooled, washed, suction filtered (to neutral), and dried at 60°C to obtain NaY ty...

Embodiment 2

[0054] The present embodiment provides a kind of preparation method of Y-type molecular sieve, and it comprises the following steps:

[0055] (1) Weigh 30.3g of water glass, 7.09g of sodium hydroxide, 2.25g of sodium metaaluminate and mix with 44mL of deionized water, stir rapidly for 1 hour, then let stand in a water bath at 40°C for 4 hours to obtain a Y-type molecular sieve directing agent.

[0056] (2) Weigh water glass, 10g Y-type molecular sieve guide agent and deionized water and mix evenly, stir for 2 hours; dissolve low partial solution (sodium hydroxide and sodium aluminate in deionized water) and aluminum sulfate solution (aluminum sulfate octadecahydrate dissolved in deionized water) into the reaction system to obtain aluminosilicate gel (SiO 2 :Al 2 o 3 : Na 2 O: H 2 O=10:1.2:15.3:160), stir until the system is uniform, then crystallize at 90°C for 24h; the obtained product is cooled, washed, suction filtered (to neutral), and dried at 60°C to obtain NaY type...

Embodiment 3

[0059] The present embodiment provides a kind of preparation method of Y-type molecular sieve, and it comprises the following steps:

[0060] (1) Weigh 20 g of water glass, 8.09 g of sodium hydroxide, 2.25 g of sodium metaaluminate and 44 mL of deionized water, stir rapidly for 1 h, and then stand in a 45°C water bath for 5 h to obtain a Y-type molecular sieve directing agent.

[0061] (2) Weigh water glass, 10g Y-type molecular sieve guide agent and deionized water and mix evenly, stir for 2 hours; dissolve low partial solution (sodium hydroxide and sodium aluminate in deionized water) and aluminum sulfate solution (aluminum sulfate octadecahydrate dissolved in deionized water) into the reaction system to obtain aluminosilicate gel (SiO 2 :Al 2 o 3 : Na 2 O: H 2 O=12:1.4:17.1:190), stir until the system is uniform, and crystallize at 100°C for 24h; the obtained product is cooled, washed, suction filtered (to neutral), and dried at 60°C to obtain NaY type molecular sieve....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com