Growth method of N-type superlattice contact layer

A superlattice and contact layer technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as improving and detrimental chip luminous efficiency and reducing contact layer Schottky voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

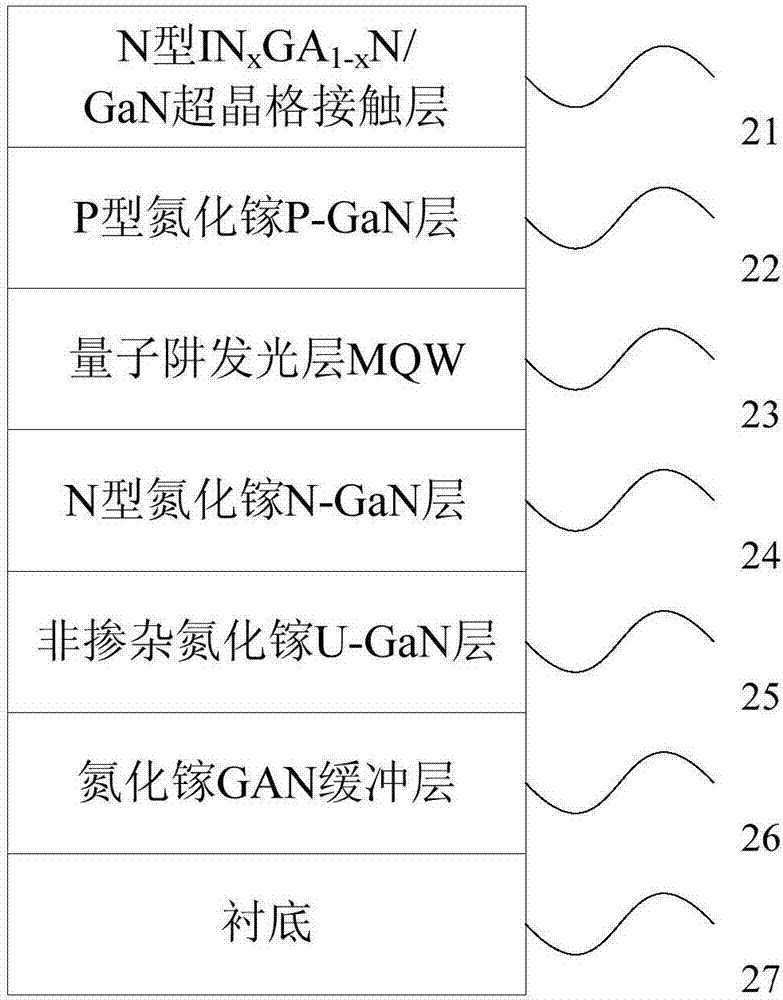

[0037]The N-type IN x GA 1-x The N / GaN superlattice contact layer is N-type (IN 0.15 GA 0.85 N / GaN) 3 Superlattice contact layer, N-type (IN 0.15 GA 0.85 N / GaN) 3 The thickness of the superlattice contact layer is 15 nm, where IN 0.15 GA 0.85 The thickness of N super is 2 nm, the thickness of GaN is 3 nm, the SiH 4 The dopant rubs at a concentration of 1.2 x 10e 21 cm -3 .

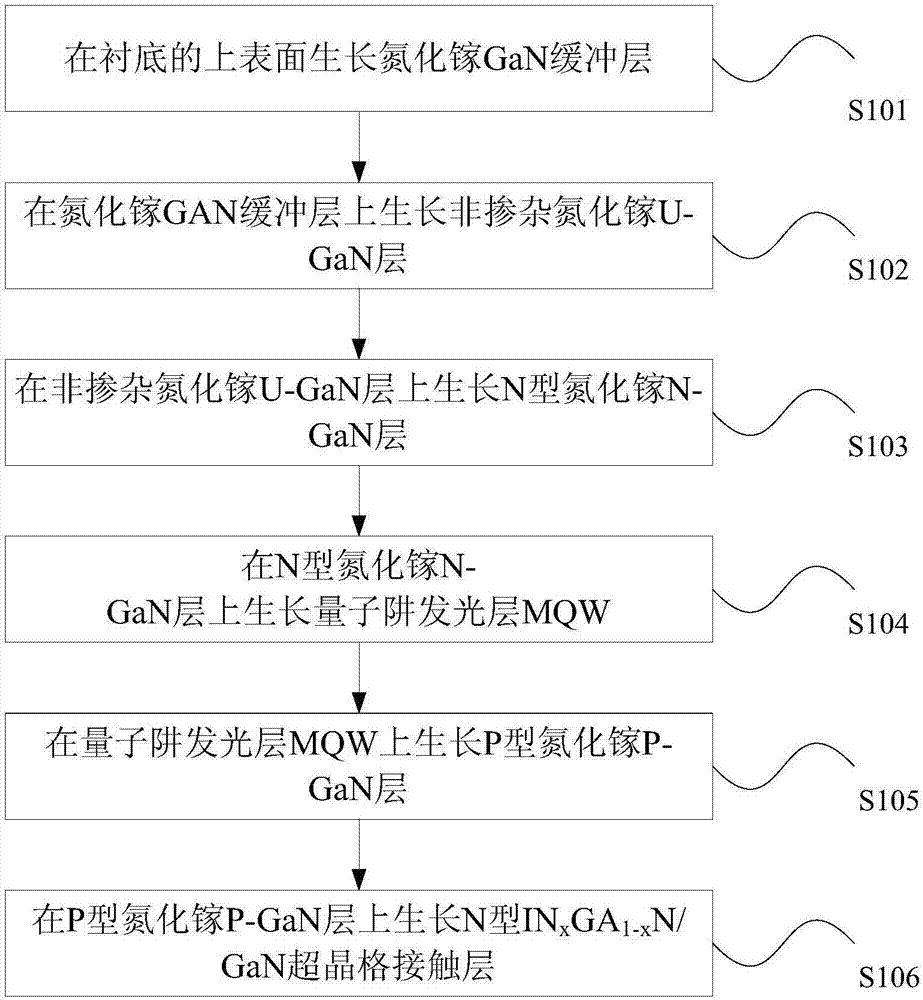

[0038] And the growth method of the N-type INGAN / GAN superlattice contact layer is described in detail, the method includes:

[0039] 1. Put the sapphire (Patterned Sapphire Substrate, PSS for short) substrate 21 into the reaction chamber, the flow ratio of N2:H2:NH3 is (0:120:0) liters per minute (Standard Liter per Minute, SLM for short), The pressure of the reaction chamber is 500 Torr, the temperature is raised to 1070° C., and stabilized for 300 seconds, and the substrate 21 is purified at high temperature.

[0040] 2. Lower the temperature to 550° C., the flow ratio of N2:H2:NH3 is (75:1...

Embodiment 2

[0047] The N-type IN x GA 1-x The N / GaN superlattice contact layer is N-type (IN 0.1 GA 0.9 N / GaN) 4 Superlattice contact layer, N-type (IN 0.1 GA 0.9 N / GaN) 4 The thickness of the superlattice contact layer is 16 nm, where N-type IN 0.1 GA 0.9 The thickness of N is 2 nm, the thickness of GaN is 2 nm, the SiH 4 The dopant rubs at a concentration of 1.9×10e 20 cm -3 -1.2×10e 21 cm -3 between.

[0048] 1. Put the sapphire (Patterned Sapphire Substrate, PSS for short) substrate 21 into the reaction chamber, the flow ratio of N2:H2:NH3 is (0:120:0) liters per minute (Standard Liter per Minute, SLM for short), The pressure of the reaction chamber is 500 Torr, the temperature is raised to 1080° C., and stabilized for 300 seconds, and the substrate is purified at high temperature.

[0049] 2. Lower the temperature to 550° C., the flow ratio of N2:H2:NH3 is (75:150:56) SLM, the pressure of the reaction chamber is controlled at 500 Torr, and a low-temperature GaN buffer l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com