Method for preparing peptide calcium by using fish bone

A technology of fish bone and peptide calcium, which is applied in the field of preparation of peptide calcium products, can solve problems such as fish bone softening, achieve the effects of promoting dissolution, improving enzymatic hydrolysis efficiency, and increasing utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

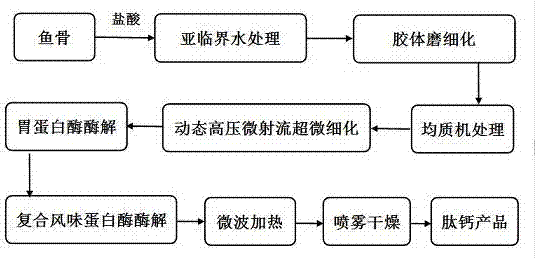

Image

Examples

Embodiment 1

[0030] 1. Subcritical water treatment fish bones

[0031] (1) Mixing fish bones with hydrochloric acid solution: mix fish bones with hydrochloric acid solution with a pH value of 2.0 at a solid-to-liquid ratio of 1:10;

[0032] (3) Subcritical water treatment: subcritical water treatment was carried out on the mixture of fish bone and hydrochloric acid, the subcritical water temperature was set at 120 °C, and the treatment time was 2.0 h.

[0033] 2. Dynamic high-pressure micro-jet ultra-fine fishbone

[0034] The colloid mill was used to treat the fishbone mixture three times, and then a 40 MPa homogenizer was used to treat it twice, and then the dynamic high-pressure micro-jet was used for ultra-fine treatment. The micro-jet pressure was set at 140 MPa, and the number of treatments was 4 times.

[0035] 3. Enzymatic hydrolysis of fish bones with protease

[0036] (1) Pepsin enzymatic hydrolysis of fish bones: Pepsin was used to enzymatically hydrolyze fish bones treated wi...

Embodiment 2

[0044] 1. Subcritical water treatment fish bones

[0045] (1) Mixing fish bones with hydrochloric acid solution: mix fish bones with hydrochloric acid solution with a pH value of 2.5 at a solid-to-liquid ratio of 1:10;

[0046] (3) Subcritical water treatment: Subcritical water treatment was performed on the mixture of fish bone and hydrochloric acid. The subcritical water temperature was set at 125 °C and the treatment time was 1.5 h.

[0047] 2. Dynamic high-pressure micro-jet ultra-fine fishbone

[0048] The colloid mill was used to treat the fishbone mixture twice, and then a homogenizer of 10-40 MPa was used to treat it twice, and then the dynamic high-pressure micro-jet was used for ultra-fine treatment. The micro-jet pressure was set at 160 MPa, and the number of treatments was 2. Second-rate.

[0049] 3. Enzymatic hydrolysis of fish bones with protease

[0050] (1) Pepsin enzymatic hydrolysis of fish bones: Pepsin was used to enzymatically hydrolyze fish bones treat...

Embodiment 3

[0058] 1. Subcritical water treatment fish bones

[0059] (1) Mixing fish bones with hydrochloric acid solution: mix fish bones with hydrochloric acid solution with a pH value of 2.0 at a solid-to-liquid ratio of 1:15;

[0060] (3) Subcritical water treatment: Subcritical water treatment was performed on the mixture of fish bone and hydrochloric acid. The subcritical water temperature was set at 130°C and the treatment time was 2.0 h.

[0061] 2. Dynamic high-pressure micro-jet ultra-fine fishbone

[0062]The fishbone mixture was treated twice with a colloid mill, then twice with a 30 MPa homogenizer, and then ultra-micronized with a dynamic high-pressure micro-jet. The pressure of the micro-jet was set at 180 MPa, and the number of treatments was three times.

[0063] 3. Enzymatic hydrolysis of fish bones with protease

[0064] (1) Pepsin enzymatic hydrolysis of fish bones: Pepsin was used to enzymatically hydrolyze fish bones treated with dynamic high-pressure micro-jet, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com