Activation and regeneration method of deactivated catalyst in process of synthesizing dimethyl oxalate by CO

A deactivated catalyst, dimethyl oxalate technology, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of promoting clean and efficient utilization, simple process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

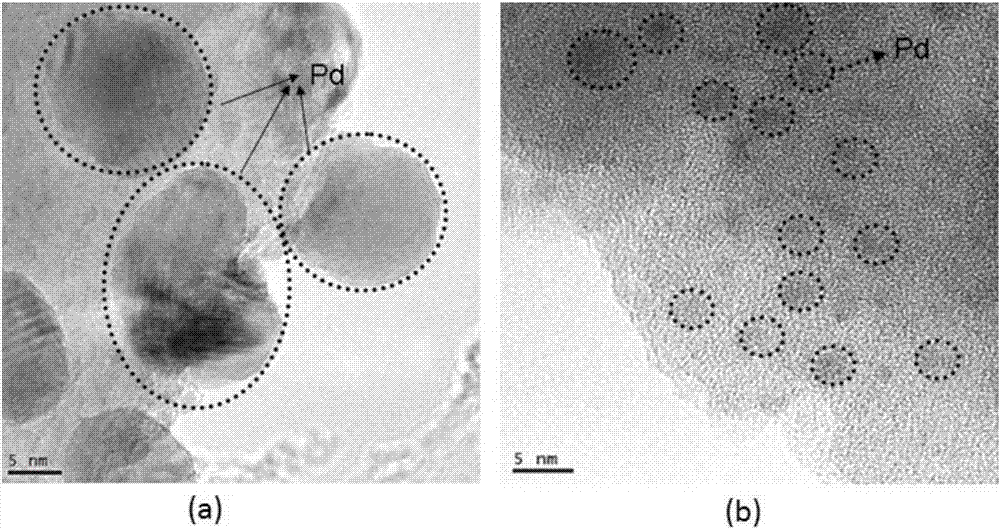

Image

Examples

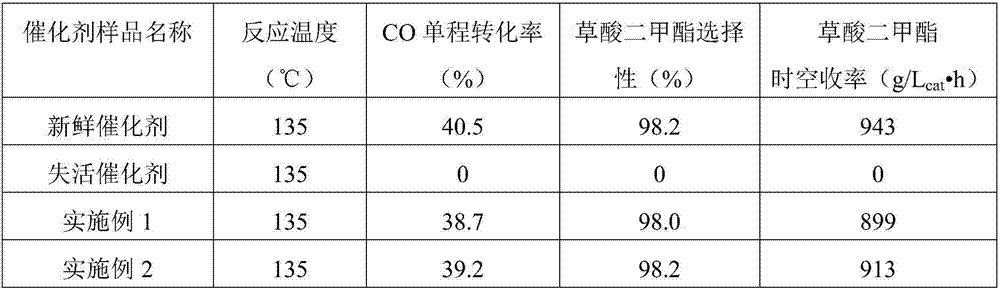

Embodiment 1

[0029] Put 10mL of deactivated catalyst and 20mL of 5mol / L sodium hydroxide solution in a 200mL reactor, and keep it in an oven at 180°C for 5 hours at a constant temperature. After the temperature drops to room temperature, the catalyst is suction-filtered and washed with water until the filtrate pH=7. The deactivated catalyst washed with alkali was soaked in 10 mL of polyethylene glycol solution with a concentration of 2 mol / L for 3 h, and after suction filtration, the catalyst was roasted in a muffle furnace at 600° C. for 4 h. Pack the calcined catalyst into a quartz tube with an inner diameter of 20mm with a heating jacket, control the heating temperature to 150°C, and feed 50mL / min N into the quartz tube through a rotameter. 2 and 50mL / min HCl, after ventilating for 5h, put the catalyst in 10mL of sodium hydroxide solution with a mass fraction of 20% and soak for 2h, suction filter, wash with distilled water until the filtrate pH=7, and then use 10mL of 30% sodium hydroxi...

Embodiment 2

[0031] Put 10mL of deactivated catalyst and 20mL of 4mol / L hexamethylenetetramine solution in a 200mL reactor, and keep it in an oven at 200°C for 6h at a constant temperature. After the temperature drops to room temperature, filter and wash the catalyst with water until the pH of the filtrate=7 . The deactivated catalyst washed with alkali was soaked in 10 mL of glucose solution with a concentration of 4 mol / L for 3 hours, and after suction filtration, the catalyst was roasted in a muffle furnace at 500°C for 6 hours. Pack the calcined catalyst into a quartz tube with an inner diameter of 20mm with a heating jacket, control the heating temperature to 180°C, and feed 30mL / min N into the quartz tube through a rotameter. 2 and 70mL / min HCl, after aeration treatment for 3h, then place the catalyst in a mixed solution of 10mL of 10% mass fraction of sodium hydroxide and sodium bicarbonate and soak for 3h, after soaking, wash the catalyst with distilled water until the filtrate pH=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com