Preparation method of lead-free high-Curie-point BaTiO3-based positive-temperature-coefficient thermal sensitive ceramic

A technology of positive temperature coefficient, heat-sensitive ceramics, applied in high-tech functional ceramics and its application fields, can solve problems such as inaccurate chemical compounding, achieve low room temperature resistivity, ensure consistency and repeatability, and high Curie temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

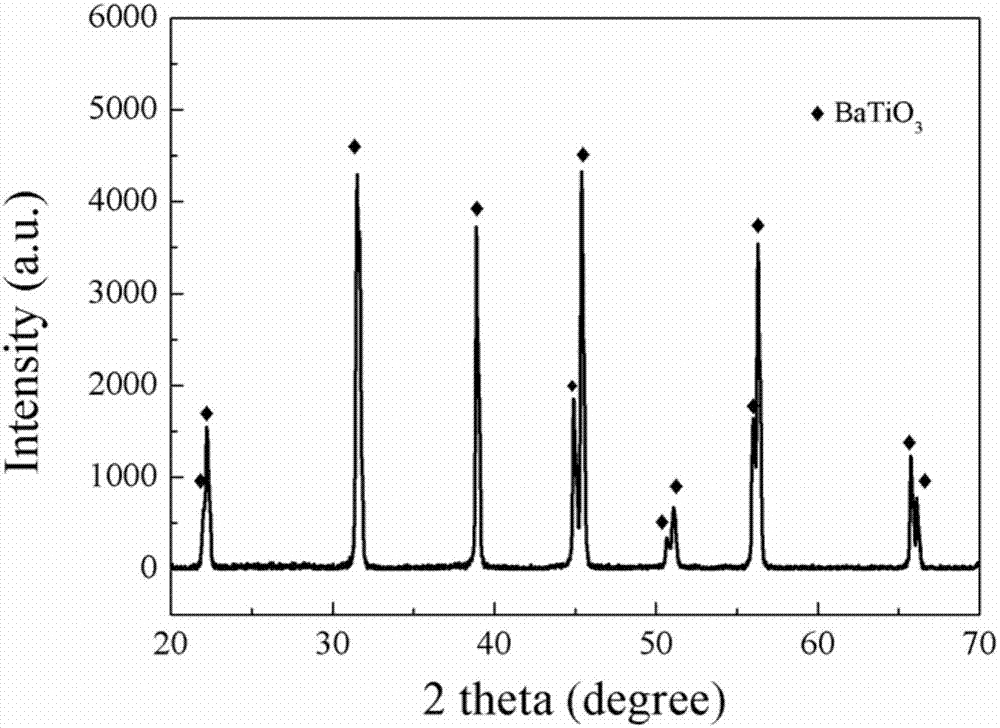

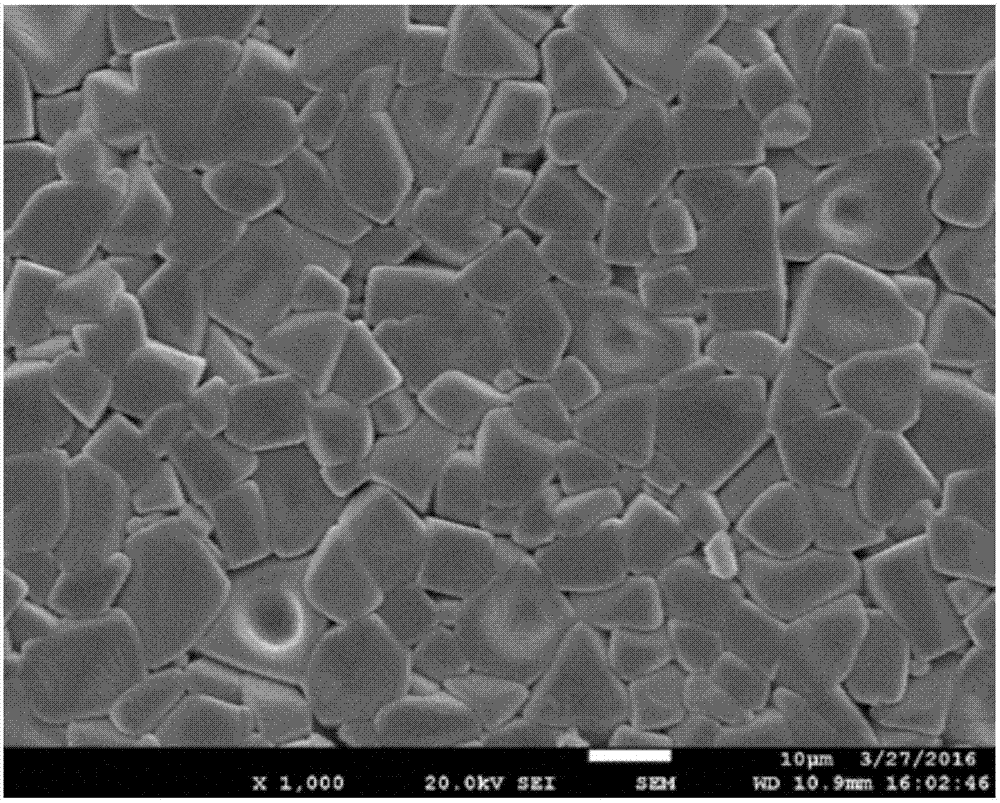

[0040] The present invention proposes a lead-free BaTiO with high Curie temperature, high lift-to-drag ratio, and low room temperature resistivity. 3 A thermosensitive ceramic based on a positive temperature coefficient and a preparation method thereof, wherein the ceramic is made of tetragonal perovskite BaTiO 3 phase as matrix, with (Bi 0.5 Na 0.5 )TiO 3 In order to increase the peak shifting agent of the Curie temperature, the rare earth oxide Ta 2 o 5 or Sm 2 o 3 Reduce room temperature resistivity and add transition metal oxide MnO 2 To improve the lift-to-drag ratio; the preparation method uses a one-pot method to prepare this lead-free BaTiO 3 Based on thermosensitive ceramics, the reduction-reoxidation sintering method is used to obtain BaTiO with excellent thermosensitive properties 3 Based on positive temperature coefficient heat-sensitive ceramics; the preparation method includes "weighing → mixing → ball milling → drying → calcining → grinding and sieving →...

Embodiment 1

[0053] Embodiment 1: BaTiO of the embodiment of the present invention 3 The manufacturing method and technological process of the base positive temperature coefficient heat-sensitive ceramics are as follows:

[0054] (1) According to the synthetic mole fraction of 91.2% BaTiO 3 powder, synthetic 8.8% (Bi 0.5 Na 0.5 )TiO 3 powder, plus a mole fraction of 0.3% Ta 2 o 5 Powder, weigh BaCO 3 、TiO 2 、 Bi 2 o 3 、Na 2 CO 3 and Ta 2 o 5 powdered reagents.

[0055] (2) Add all the reagents weighed in proportion to the ball mill tank of the planetary ball mill, and add 10 times the mass of ZrO 2 Grinding balls and 5 times the mass of anhydrous ethanol solvent, ball milling for 6 hours.

[0056] (3) Dry the finely ground and mixed slurry in an atmospheric drying oven at a temperature of 80° C. for 72 hours.

[0057] (4) The mixed powder after ball milling and drying is put into a crucible, and then calcined in a muffle furnace at a temperature of 900° C. for 4 hours.

[...

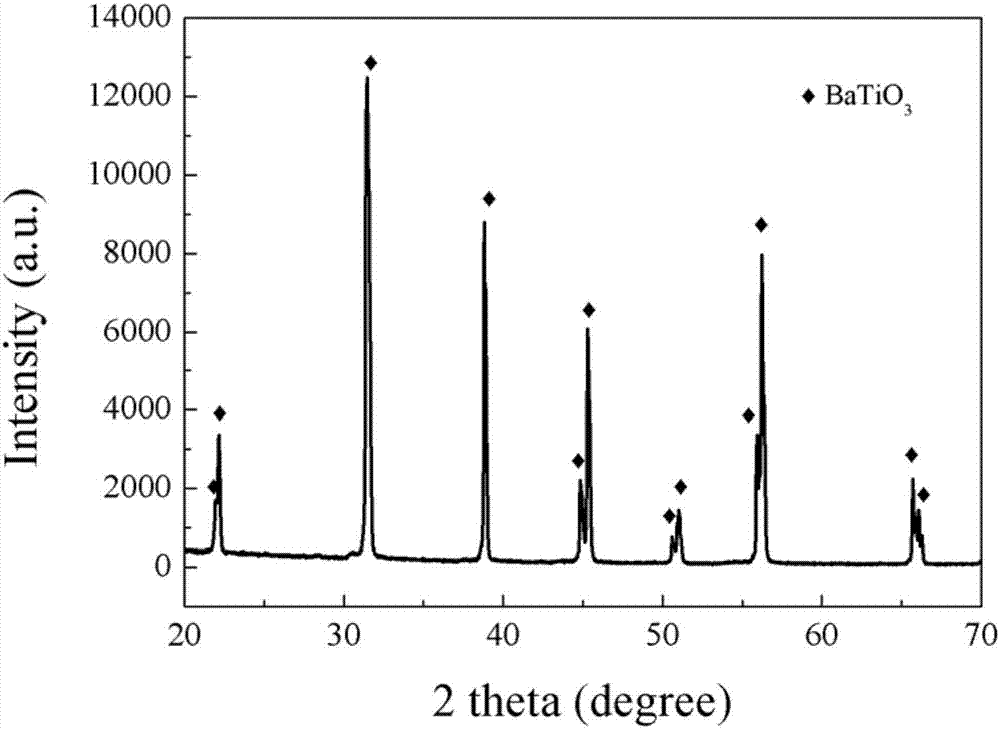

Embodiment 2

[0065] Embodiment 2: BaTiO of the embodiment of the present invention 3 The manufacturing method and technological process of the base positive temperature coefficient heat-sensitive ceramics are as follows:

[0066] (1) BaTiO with a synthetic mole fraction of 92% 3 powder, synthetic 8% (Bi 0.5 Na 0.5 )TiO 3 powder, plus a mole fraction of 0.3% Ta 2 o 5 powder and 0.04 mol% MnO 2 Powder, weigh BaCO 3 、TiO 2 、 Bi 2 o 3 、Na 2 CO 3 、 Ta 2 o 5 and MnO 2 powdered reagents.

[0067] (2) Add all the reagents weighed in proportion to the ball mill jar of the stirring ball mill, and add 10 times the mass of ZrO 2 Grinding balls and 5 times the mass of anhydrous ethanol solvent, ball milling for 18 hours.

[0068] (3) In an atmospheric pressure drying oven, dry the finely ground and mixed slurry at a temperature of 90° C. for 48 hours.

[0069] (4) Put the mixed powder after ball milling and drying into a crucible, and then calcinate in a muffle furnace at a temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

| Room temperature resistivity | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com