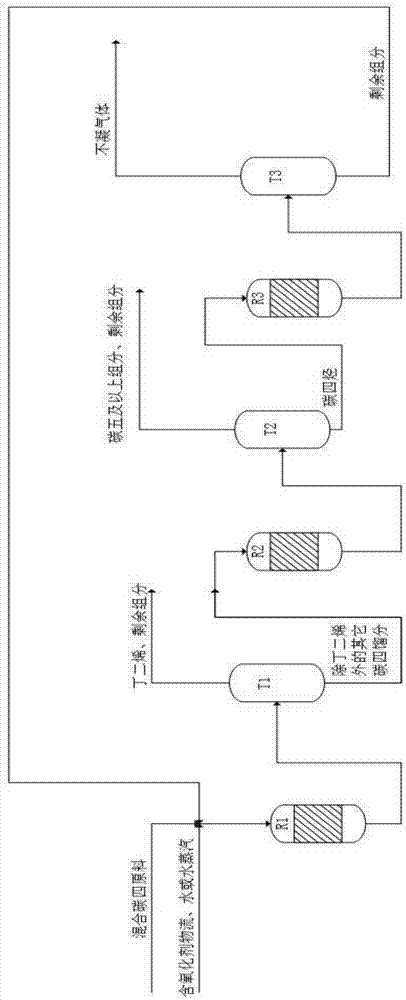

Conversion and utilization process for mixed C4

A technology of mixing C4 and process, applied in the field of oil refining, which can solve the problems of difficult to achieve catalytic effect, high energy consumption, and inability to solve catalyst wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] This embodiment provides an oxidative dehydrogenation catalyst, and the specific preparation process of the catalyst includes the following steps:

[0085] (1) At first the precursor zinc nitrate hexahydrate 1785g of metal A used, the precursor nickel nitrate hexahydrate 90g of B, the precursor calcium chloride hexahydrate 197.1g of C, the precursor tungsten trioxide 5g of D are ground into 50 mesh microspheres; secondly, zinc nitrate hexahydrate is divided into two parts of 1071g and 714g according to the ratio of 60% and 40%, and nickel nitrate hexahydrate, calcium chloride hexahydrate and tungsten trioxide are mixed uniformly;

[0086] (2) Configure 8.5L 2mol / L ferric nitrate solution, under stirring conditions, first gradually add 1071g zinc nitrate hexahydrate into the ferric nitrate solution, react for 70 minutes, then slowly add nickel nitrate hexahydrate, chlorinated hexahydrate The mixture of calcium and tungsten trioxide, after reacting for 90 minutes, slowly ...

Embodiment 2

[0091] This embodiment provides an oxidative dehydrogenation catalyst, and the specific preparation process of the catalyst includes the following steps:

[0092] (1) Firstly, 622.5g of copper nitrate precursor of metal A used, 116.4g of cobalt nitrate hexahydrate precursor of B, 20.8g of barium chloride precursor of C, and 12g of tungsten trioxide precursor of D are ground to 70 mesh Microspherical; Secondly, copper nitrate is divided into two parts of 404.6g and 217.9g according to the ratio of 65% and 35%, and cobalt nitrate hexahydrate, barium chloride and tungsten trioxide are mixed uniformly;

[0093] (2) Configure 36L of 0.5mol / L ferric nitrate solution, under stirring conditions, first gradually add 404.6g of copper nitrate to the ferric nitrate solution, react for 60 minutes, then slowly add nickel nitrate hexahydrate and calcium chloride hexahydrate And the mixture of tungsten trioxide, after reacting for 70 minutes, slowly add 217.9g of copper nitrate, and after rea...

Embodiment 3

[0098] This embodiment provides an oxidative dehydrogenation catalyst, and the specific preparation process of the catalyst includes the following steps:

[0099] (1) First, 297.5g of the precursor of metal A, zinc nitrate hexahydrate, 25.4g of manganese sulfate monohydrate, the precursor of metal A, 266g of strontium chloride hexahydrate, the precursor of C, and 13.9g of tungsten trioxide, the precursor of metal Grinding into 40 mesh microspheres; secondly, zinc nitrate hexahydrate is divided into two parts of 208.3g and 89.2g according to the ratio of 70% and 30%, and manganese sulfate monohydrate, strontium chloride hexahydrate and tungsten trioxide are mixed evenly;

[0100] (2) Configure 10L of 0.7mol / L ferric nitrate solution, under stirring conditions, first gradually add 208.3g of zinc nitrate hexahydrate into the ferric nitrate solution, react for 30 minutes, then slowly add manganese sulfate monohydrate and chlorine hexahydrate The mixture of strontium chloride and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com