Silicon rubber-carbon sponge composite material and preparation method and application thereof

A composite material and carbon sponge technology, which is applied in the field of silicone rubber-carbon sponge composite material and its preparation, can solve problems such as fiber breakage, poor sensor sensitivity, and damage to the conduction network of electrical signals, and achieve cheap and easy preparation of materials. The effect of simple method and broad application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

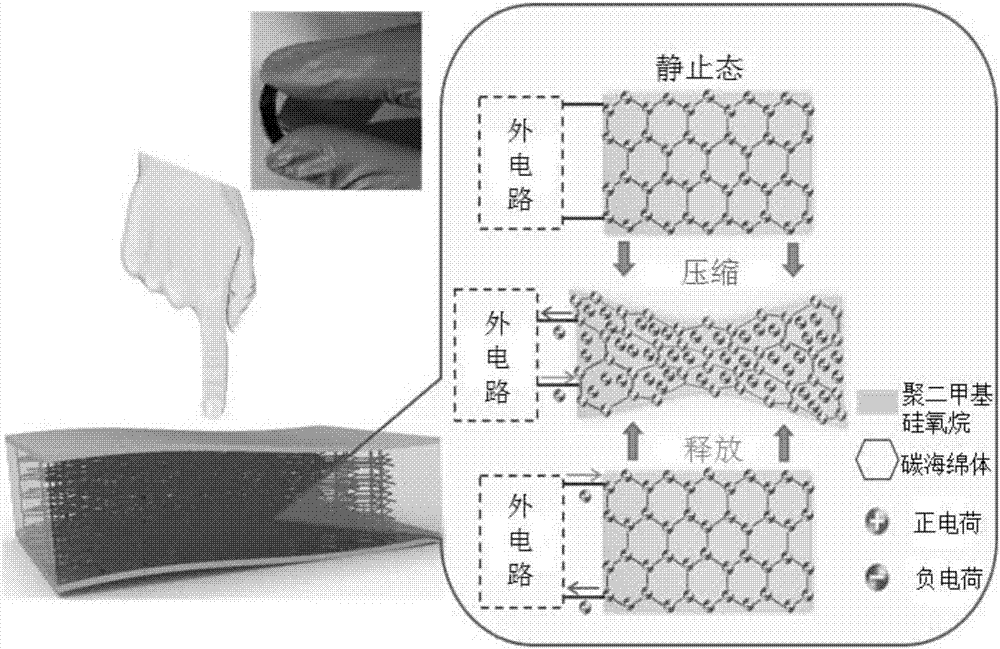

[0046] In yet another embodiment of the present invention, a method for preparing a silicone rubber-carbon sponge composite material is provided, comprising the steps of:

[0047] (1) The sponge is cleaned with ultrasonic waves, and the treated sponge is dried and decomposed by high-temperature carbonization to obtain a carbon sponge;

[0048] (2) placing the carbon sponge obtained in step (1) into a carbon nanotube solution for immersion treatment, taking out and drying to obtain a carbon nanotube-carbon sponge composite material;

[0049] (3) Mix and stir the insulator polymer and the curing agent to remove the foam, fill it into the carbon sponge, and cure it at high temperature, so that the insulator polymer is solidified on the carbon nanotube-carbon sponge composite material.

[0050] Wherein, in the step (1), the sponge is a polyester sponge or a polyether sponge, preferably, the sponge is a melamine-formaldehyde resin foam;

[0051] The specific steps of cleaning are ...

Embodiment 1

[0066] A preparation method of silicone rubber-carbon sponge composite material, comprising the steps of:

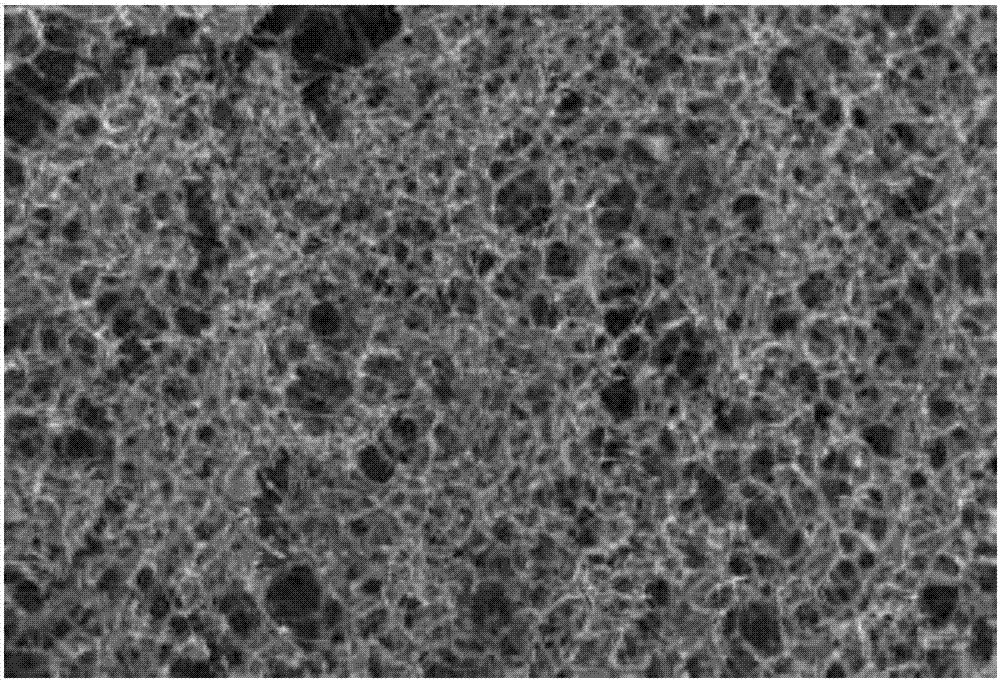

[0067] (1) The melamine-formaldehyde resin foam material is ultrasonically cleaned with acetone, ethanol and distilled water in sequence, and then dried in the air at 60°C before use; the dried sponge is carbonized and decomposed at a high temperature of 1000°C for 2 hours to obtain a carbon sponge ;

[0068] (2) Multi-walled carbon nanotubes and sodium dodecylbenzenesulfonate are added to the deionized aqueous solution by 2:1 mass ratio to prepare the multi-walled carbon nanotubes solution of 0.5g / L, and step (1) is processed The obtained carbon sponge is soaked in the multi-walled carbon nanotube solution for 10 minutes, taken out and dried at 60°C to obtain the carbon nanotube-carbon sponge composite material;

[0069] (3) Mix the polydimethylsiloxane and the curing agent in a mass ratio of 10:1 with a defoaming mixer for 10 minutes, remove the foam for 5 minutes, fi...

Embodiment 2

[0071] A preparation method of silicone rubber-carbon sponge composite material, comprising the steps of:

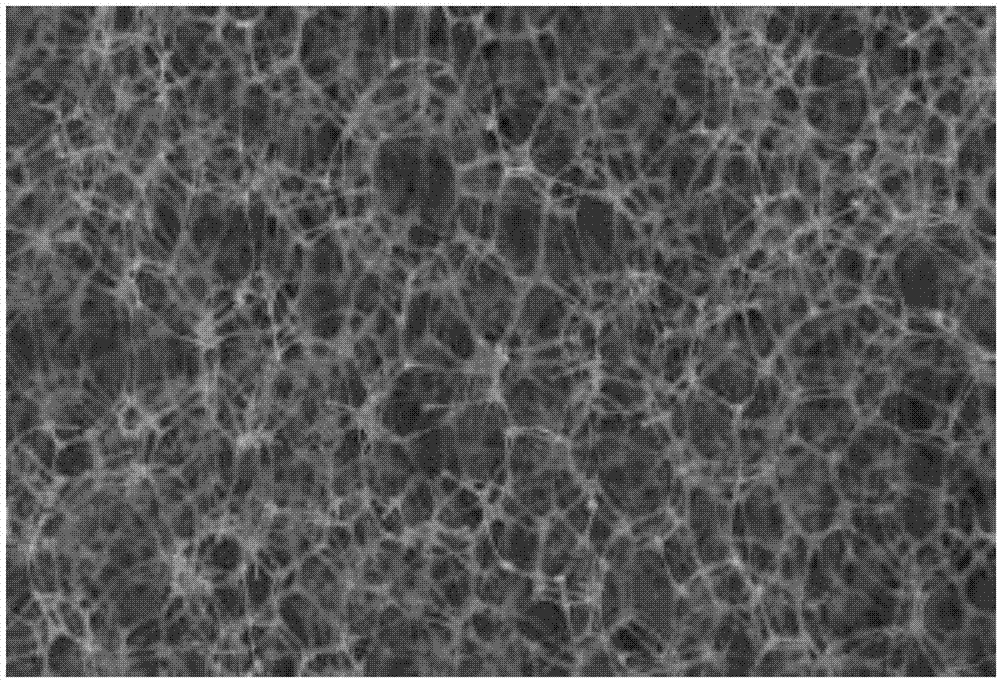

[0072] (1) The melamine-formaldehyde resin foam material is ultrasonically cleaned with acetone, ethanol and distilled water in sequence, and then dried in the air at 60°C before use; the dried sponge is carbonized and decomposed at a high temperature of 900°C for 2 hours to obtain carbon sponge;

[0073] (2) Multi-walled carbon nanotubes and sodium dodecylbenzenesulfonate are added to the deionized aqueous solution by 2:1 mass ratio to prepare the multi-walled carbon nanotubes solution of 0.5g / L, and step (1) is processed The obtained carbon sponge is soaked in the multi-walled carbon nanotube solution for 10 minutes, taken out and dried at 60°C to obtain the carbon nanotube-carbon sponge composite material;

[0074] (3) Mix the polydimethylsiloxane and the curing agent in a mass ratio of 10:1 with a defoaming mixer for 10 minutes, remove the foam for 5 minutes, fill i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com