Modified seamless trolley wire insulation material and preparation method thereof

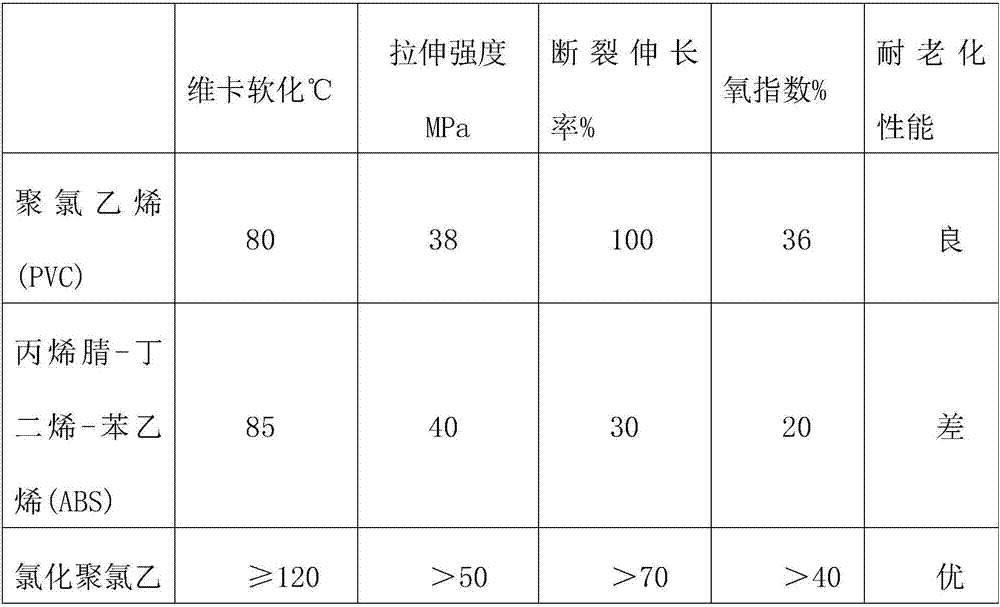

An insulating material and seamless technology, which is applied in the field of modified seamless trolley line insulating material and its preparation, can solve the problems of poor low temperature impact resistance, poor aging resistance, and high temperature resistance, etc. Excellent high-temperature performance, improved processing performance, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

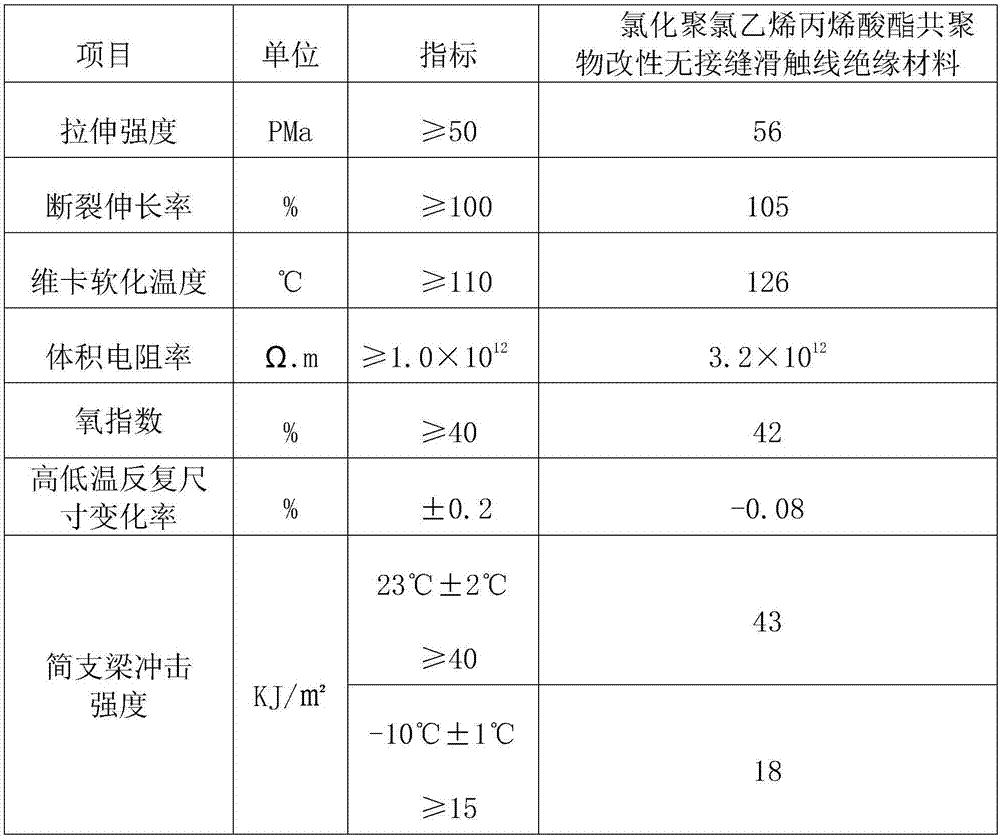

[0025] A modified seamless trolley line insulating material, the chlorinated polyvinyl chloride acrylate copolymer modified seamless trolley line insulating material is composed of the following components in parts by mass: chlorinated polyvinyl chloride resin 100 2 parts of acrylate copolymer processing modifiers; 8 parts of acrylate copolymer impact modifiers; 30 parts of common vinyl chloride 5 type resins; 4 parts of composite stabilizers; 2.0 parts of lubricants; 15 parts of calcium carbonate; 1.6 parts of pigment.

[0026] Wherein, the chlorine content of the chlorinated polyvinyl chloride resin is more than 67%, the acrylate copolymer processing modifier is K-125, and the acrylate copolymer impact modifier is KM-355, so The composite stabilizer is a calcium-zinc composite stabilizer.

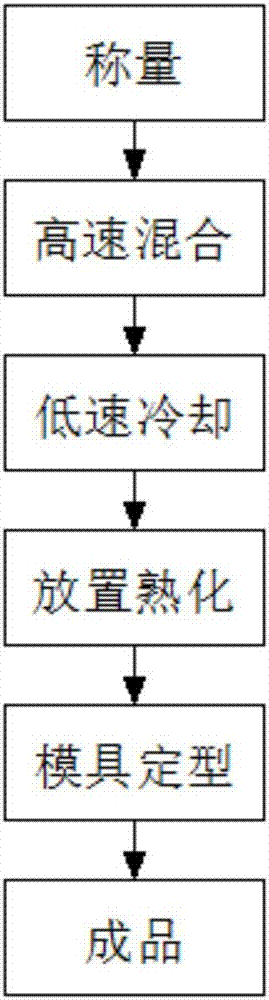

[0027] A preparation method of a modified seamless trolley line insulating material, comprising the following steps: weighing, high-speed mixing, low-speed cooling, standing and aging, m...

Embodiment 2

[0035] A modified seamless trolley line insulating material, the chlorinated polyvinyl chloride acrylate copolymer modified seamless trolley line insulating material is composed of the following components in parts by mass: chlorinated polyvinyl chloride resin 150 4 parts of acrylate copolymer processing modifiers; 10 parts of acrylate copolymer impact modifiers; 40 parts of common vinyl chloride 5 type resins; 8 parts of composite stabilizers; 3.0 parts of lubricants; 25 parts of calcium carbonate; Pigment 2.0 parts.

[0036] Wherein, the chlorine content of the chlorinated polyvinyl chloride resin is more than 67%, the processing modifier of the acrylate copolymer is K-125, and the impact modifier of the acrylate copolymer is KM-355, so The composite stabilizer is a calcium-zinc composite stabilizer.

[0037] A preparation method of a modified seamless trolley line insulating material, comprising the following steps: weighing, high-speed mixing, low-speed cooling, standing ...

Embodiment 3

[0045] A modified seamless trolley line insulating material, the chlorinated polyvinyl chloride acrylate copolymer modified seamless trolley line insulating material is composed of the following components in parts by mass: chlorinated polyvinyl chloride resin 130 3 parts of acrylate copolymer processing modifiers; 9 parts of acrylate copolymer impact modifiers; 35 parts of common vinyl chloride 5 type resins; 6 parts of composite stabilizers; 2.5 parts of lubricants; 20 parts of calcium carbonate; 1.8 parts of pigment.

[0046] Wherein, the chlorine content of the chlorinated polyvinyl chloride resin is more than 67%, the acrylate copolymer processing modifier is K-125, and the acrylate copolymer impact modifier is KM-355, so The composite stabilizer is a calcium-zinc composite stabilizer.

[0047] A preparation method of a modified seamless trolley line insulating material, comprising the following steps: weighing, high-speed mixing, low-speed cooling, standing and aging, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com