A porous long-lasting luminescent material and its preparation method

A technology for long afterglow luminescence and tablet pressing, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of low brightness and insufficient afterglow time, and achieve the effects of increasing light absorption, improving luminescence performance, and improving refraction and diffuse reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the above-mentioned porous long-lasting luminescent material of the present invention is specifically implemented according to the following steps:

[0031] Step 1, raw material preparation: MCO 3 , SiO 2 , MgO, Eu 2 o 3 、Dy 2 o 3 By chemical expression M 2-x-y MgSi 2 o 7 :xEu 2+ ,yDy 3+ The required component ratio is weighed, where M is one of Sr, Ca, Ba, 0.01≤x≤0.06, 0.01≤y≤0.1, mixed evenly, and ground for 30-60 minutes to obtain the mixed raw material A;

[0032] Step 2, pre-calcining the mixed raw material A prepared in step 1 for the first time, the firing temperature is 900°C-1100°C, and the firing time is 2-4h;

[0033] Step 3. Add a pore-forming agent to the mixed raw material A after the first pre-calcination in step 2. The mass of the pore-forming agent is 1% to 10% of the mass of the mixed raw material A. Mix evenly and grind for 30-60 minutes, and then place In the tablet press, the pressure of the tablet press is set t...

Embodiment 1

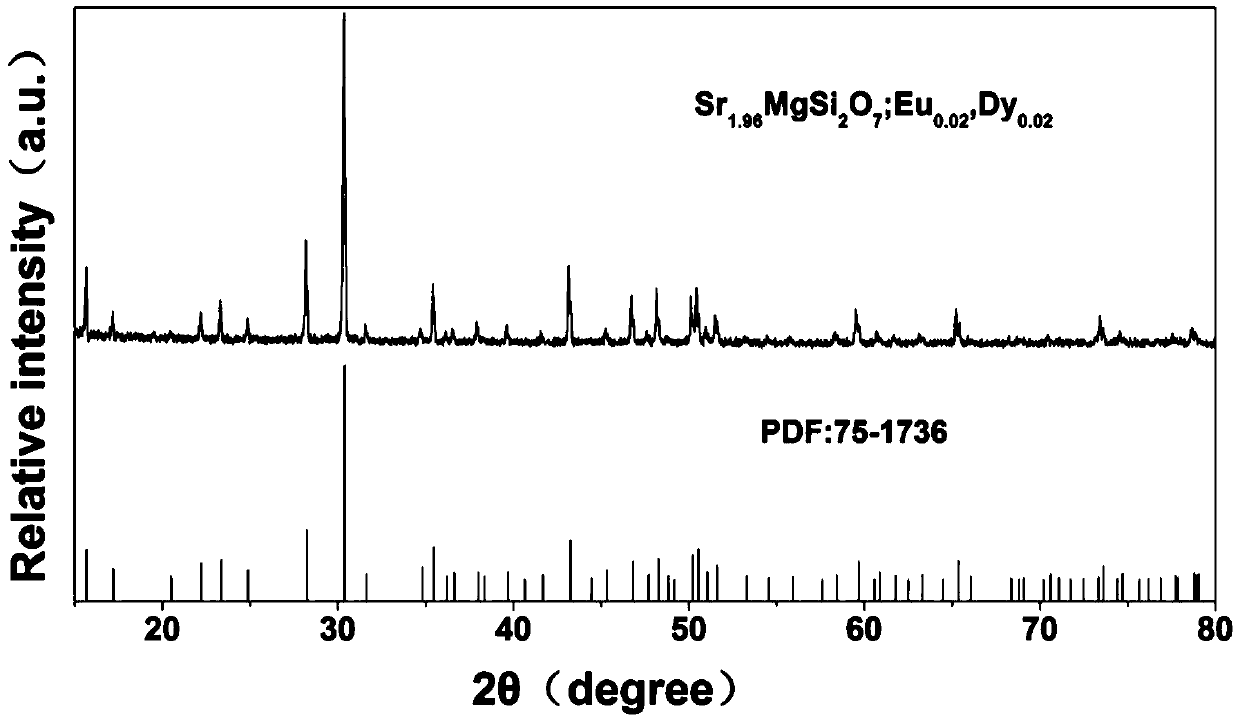

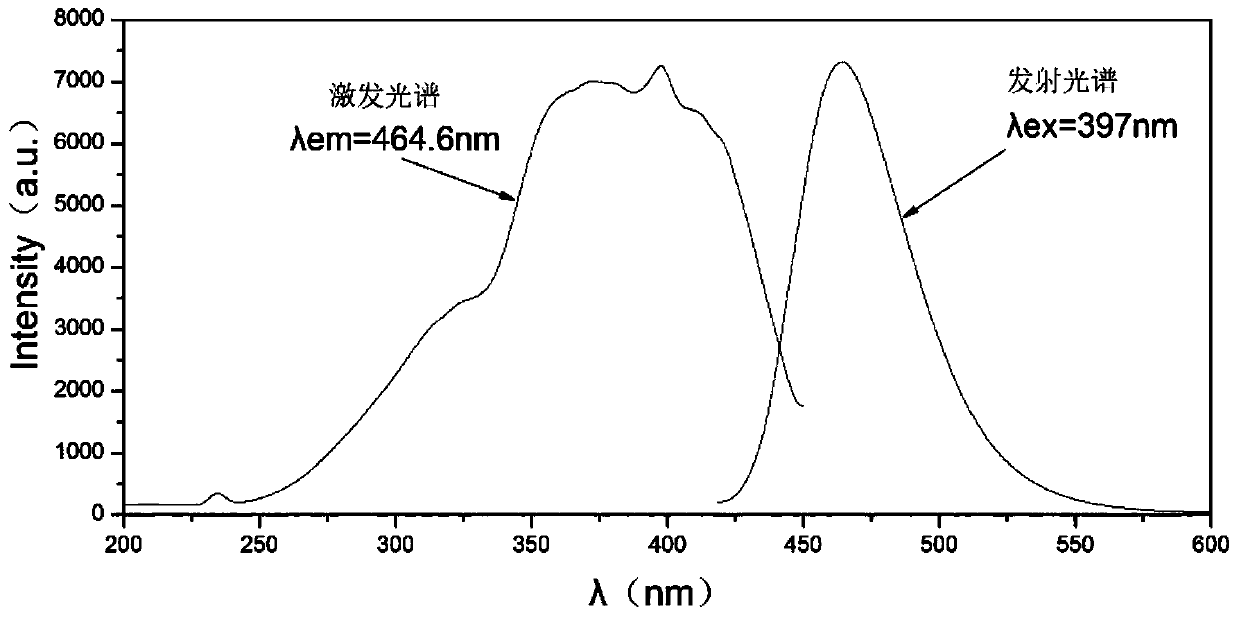

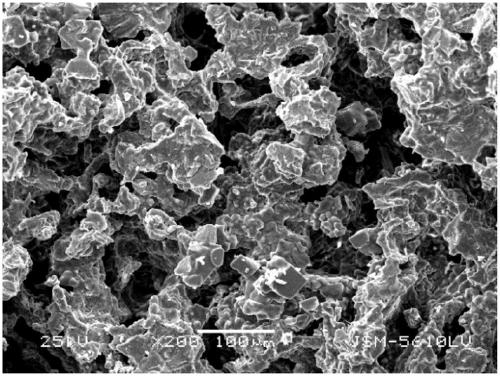

[0045] Chemical composition formula Sr 1.96 MgSi 2 o 7 :0.02Eu 2+ ,0.02Dy 3+ Preparation of porous long-lasting luminescent material:

[0046] Step 1. Take the x value as 0.02, the y value as 0.02, M as Sr, and weigh the strontium carbonate (SrCO 3 , purity is 99.0%) 1.4467g, magnesium oxide (MgO, purity is 98.5%) 0.2015g, silicon dioxide (SiO 2 , purity is 98.0%) 0.6048g, europium oxide (Eu 2 o 3 , purity is 99.99%) 0.01759g, dysprosium oxide (Dy 2 o 3 , purity is 99.99%) 0.01865g, mix uniformly, grind 60min, obtain mixed raw material A;

[0047] Step 2. Put the mixed raw material A obtained in step 1 into a corundum crucible, place it in a rapid heating resistance furnace, raise the temperature to 1100°C in an air atmosphere, keep it warm for 4 hours, cool with the furnace, and take it out after cooling to room temperature;

[0048] Step 3, add starch in the mixed raw material A after the firing of step 2 gained, starch is 5% of the quality of mixed raw material A,...

Embodiment 2

[0053] Chemical composition formula Sr 1.93 MgSi 2 o 7 :0.06Eu 2+ ,0.01Dy 3+ Preparation of porous long-lasting luminescent material:

[0054] Step 1. Take the x value as 0.06, the y value as 0.01, M as Sr, and weigh the strontium carbonate (SrCO 3 , purity is 99.0%) 1.4245g, magnesium oxide (MgO, purity is 98.5%) 0.2015g, silicon dioxide (SiO 2 , purity is 98.0%) 0.6048g, europium oxide (Eu 2 o 3 , purity is 99.99%) 0.05277g, dysprosium oxide (Dy 2 o 3 , the purity is 99.99%) 0.009325g, mixed uniformly and ground for 30min to obtain mixed raw material A;

[0055] Step 2. Put the mixed raw material A obtained in step 1 into a corundum crucible, place it in a rapid heating resistance furnace, raise the temperature to 1100°C in an air atmosphere, keep it warm for 3 hours, cool with the furnace, and take it out after cooling to room temperature;

[0056] Step 3. Add ammonium bicarbonate to the fired mixed raw material A obtained in step 2. The ammonium bicarbonate is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com