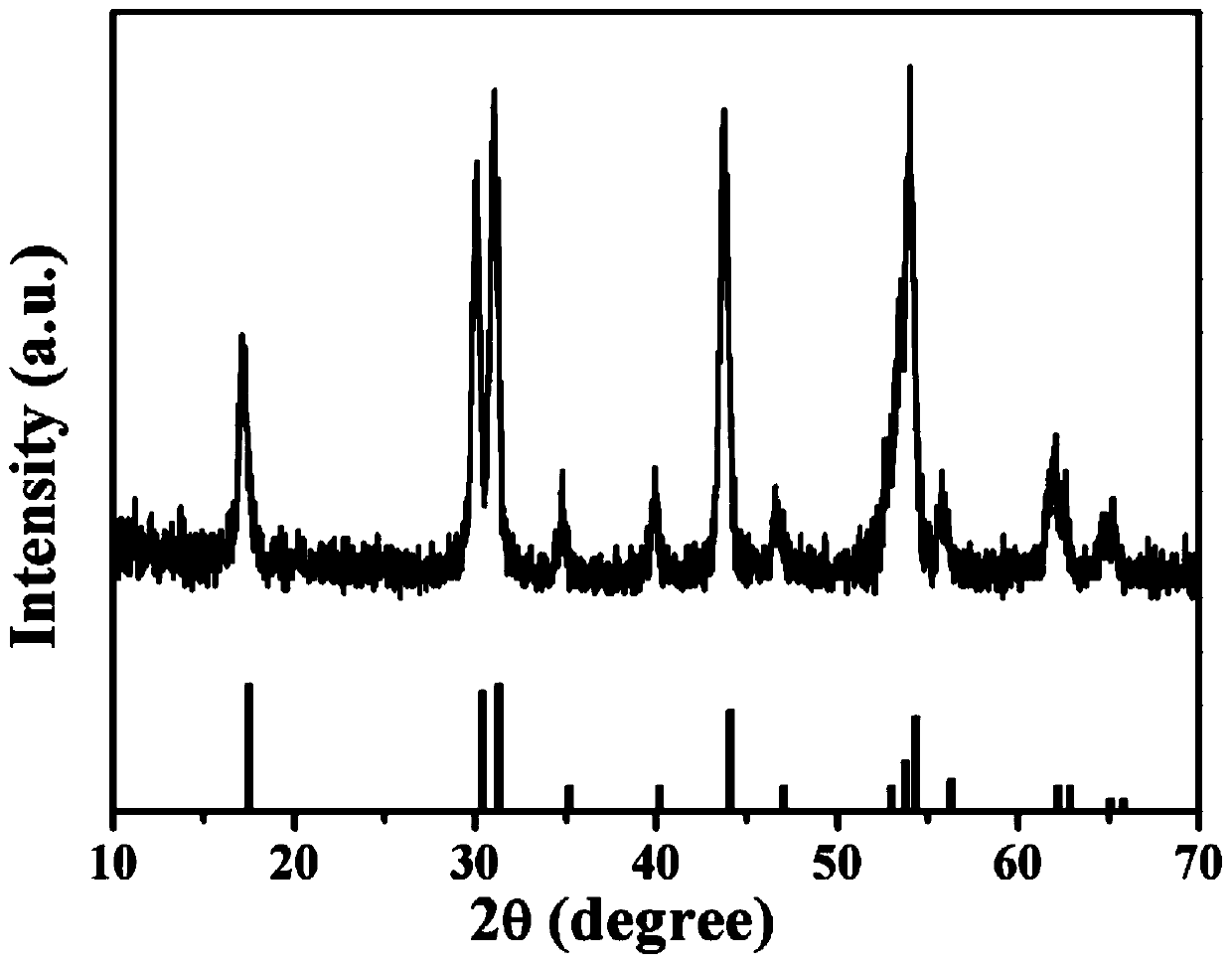

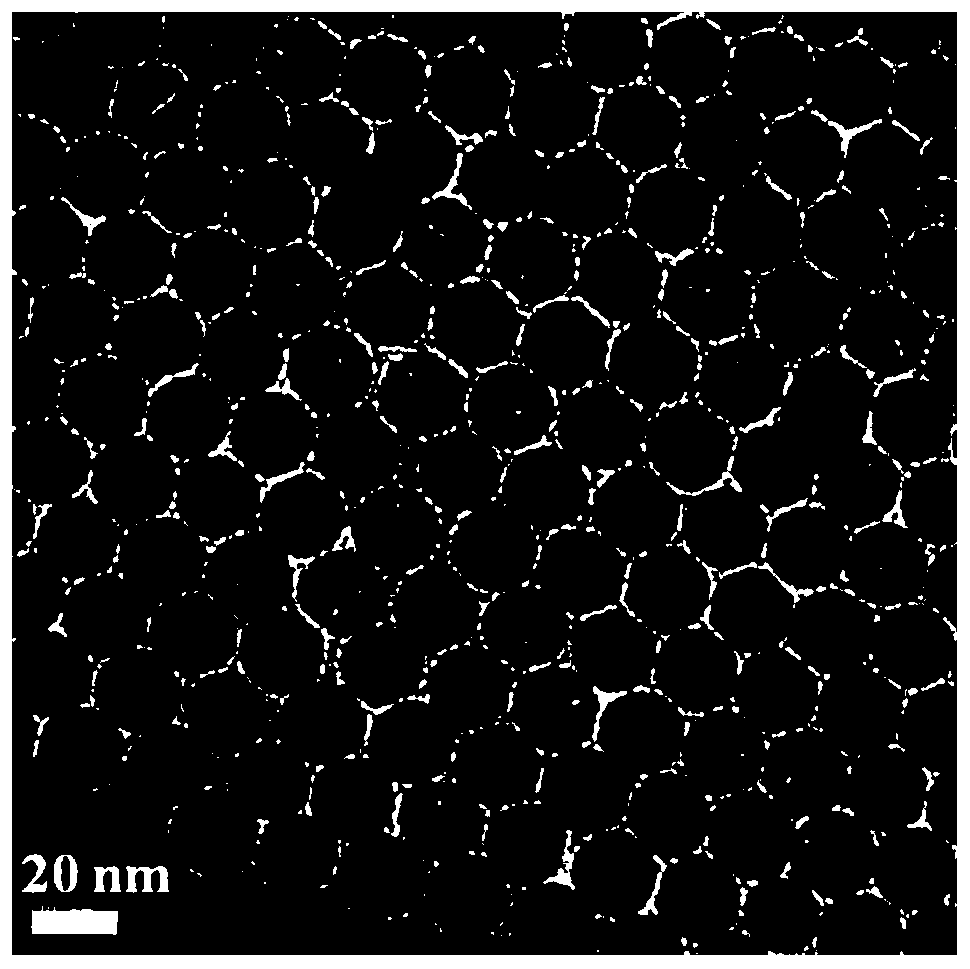

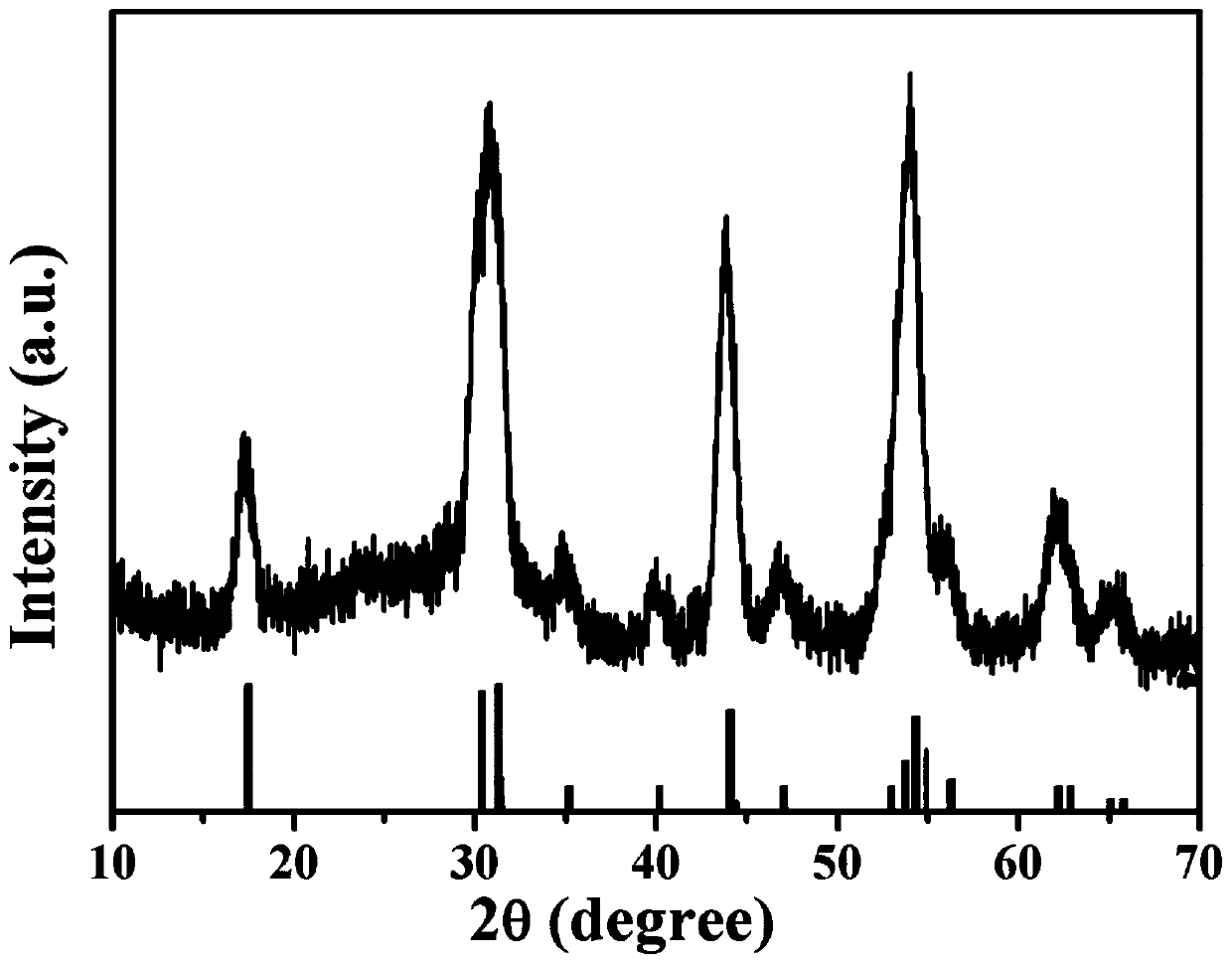

A kind of ultra-small size hexagonal phase nano-matrix material and preparation method thereof

A technology of nano-matrix and matrix material, applied in luminescent materials, nano-technology, nano-optics, etc., can solve the problem of large size of nano-materials, and achieve the effect of low luminous threshold and high luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] First prepare the rare earth salt, each composition and the mole percentage in the rare earth salt are 76% of rare earth lutetium chloride, 20% of rare earth ytterbium chloride, 2% of rare earth erbium chloride, and 2% of rare earth neodymium chloride. Put the rare earth salt, 15mL octadecene, and 6mL oleic acid in a 100mL three-necked flask to obtain a rare earth solution. Under the protection of argon, the rare earth solution was heated and stirred while heating. When the heating temperature reached 50°C, it was kept for 20 Minutes, then continue to heat when the temperature reaches 160 ° C for 30 minutes, then cool to room temperature to obtain the first solution.

[0044] Dissolve 2.5mmol sodium hydroxide in 8mL methanol solution to prepare a 0.31mol / L sodium source methanol solution, and dissolve 4mmol ammonium fluoride in 8mL methanol solution to prepare a 0.5mol / L ammonium fluoride methanol solution. The source methanol solution and the ammonium fluoride methanol...

Embodiment 2

[0047] First prepare the rare earth salt, each component in the rare earth salt and its mole percentage are 90% of rare earth ytterbium chloride, 1% of rare earth thulium chloride, and 9% of rare earth gadolinium chloride. 1. Place 6mL oleic acid in a 100mL three-necked flask to obtain a rare earth solution. Under the protection of argon, heat the rare earth solution and stir while heating. When the heating temperature reaches 70°C, keep it warm for 30 minutes, and then continue heating when the temperature When it reaches 160°C, keep it warm for 30 minutes and then cool to room temperature to obtain the first solution.

[0048] Dissolve 2.5mmol sodium hydroxide in 8mL methanol solution to prepare a 0.31mol / L sodium source methanol solution, and dissolve 4mmol ammonium fluoride in 8mL methanol solution to prepare a 0.5mol / L ammonium fluoride methanol solution. The source methanol solution and the ammonium fluoride methanol solution were successively added dropwise in the first...

Embodiment 3

[0051] First prepare the rare earth salt, each component in the rare earth salt and its mole percentage is 99.9% of rare earth ytterbium chloride (89.8% of rare earth ytterbium chloride is used as matrix material, 10% of rare earth ytterbium chloride is used as sensitizer) and rare earth Erbium chloride 0.1%, put the configured 1mmol rare earth salt, 18mL octadecene, and 3mL oleic acid into a 100mL three-necked flask to obtain a rare earth solution. Under the protection of argon, the rare earth solution is heated, and the Stir, keep warm for 30 minutes when the heating temperature reaches 55°C, then continue heating, keep warm for 30 minutes when the temperature reaches 160°C, then cool to room temperature to obtain the first solution.

[0052] Dissolve 2mmol sodium chloride in 6mL methanol solution to prepare a 0.33mol / L sodium source methanol solution, dissolve 6mmol ammonium fluoride in 10mL methanol solution to prepare a 0.6mol / L ammonium fluoride methanol solution, and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com